Efficient screening device for quartz sand production

A screening device, quartz sand technology, applied in the direction of screen, solid separation, grid, etc., can solve the problems of low screening efficiency and inability to screen, and achieve high screening efficiency, improve efficiency, and improve the effect of discharging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

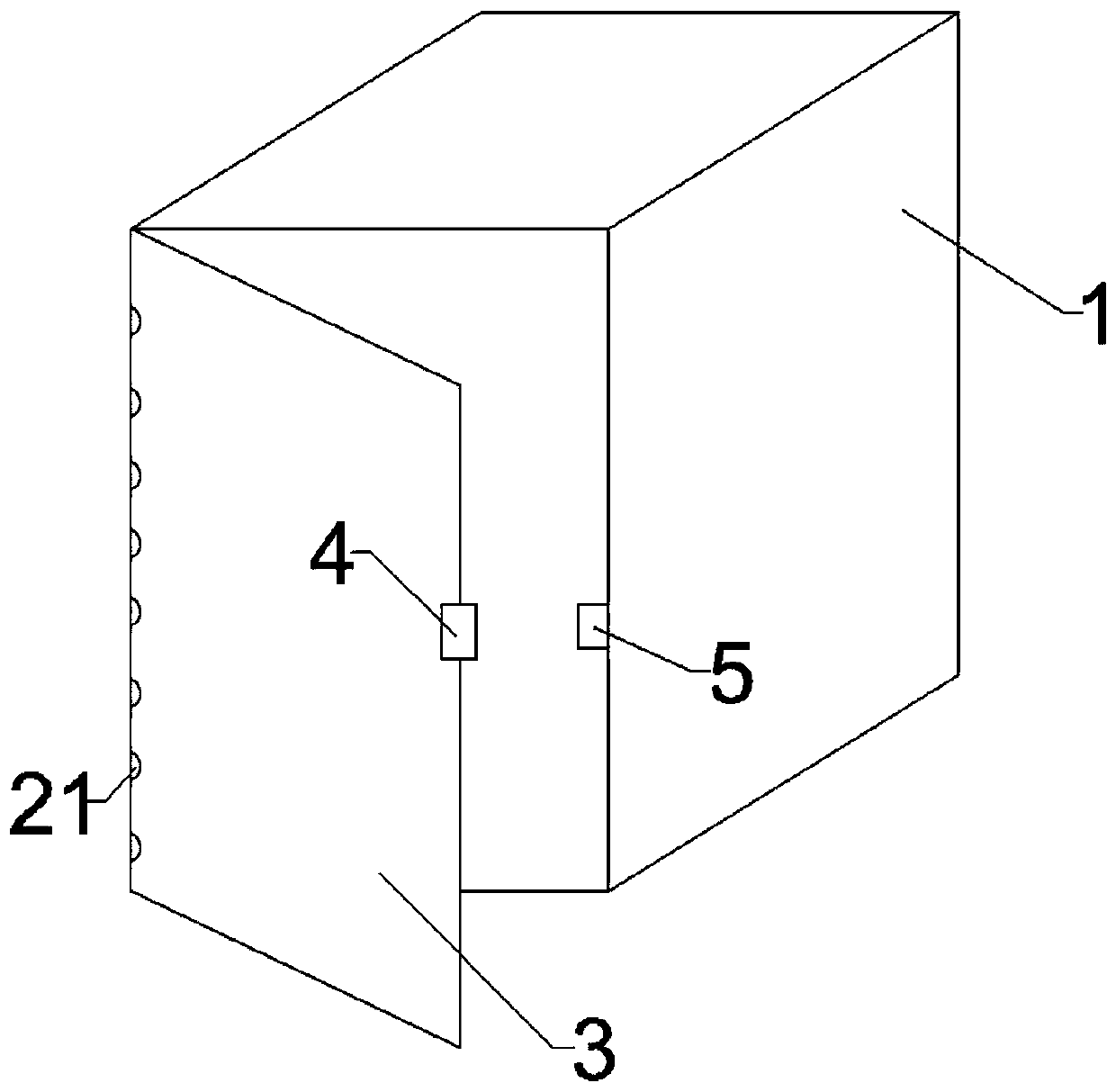

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as Figure 1-4 As shown, a high-efficiency screening device for quartz sand production includes a box body 1 and a mounting seat 2. The box body 1 is connected with a closed door 3 through a movable shaft 21. The closed door 3 is provided with a lock block 4, and the lock block 4 is connected to the box body. The body 1 is provided with a lock groove 5 for cooperating setting, and the front and rear sides of the installation seat 2 are provided with electric telescopic rods 6, and the two electric telescopic rods 6 are jointly connected with the bottom of the box body 1, and the top of the box body 1 is provided with a feed port 7 for feeding Just below the port 7 is located in the area between the two partitions 19, and the bottom is provided with a discharge port 8; the quartz sand enters the box body 1 from the feed port 7, and the partition 19 can isola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com