Asynchronous rib spalling control device of isolated coal pillar composite type coal wall

A control device and composite technology, applied in the installation of bolts, pillars/brackets, mining equipment, etc., can solve the problems affecting the control stability of non-synchronous blades, the fracture of hinged shafts and hinged columns, and the failure of hydraulic support support. It achieves the effect of convenient radial and axial support, preventing the blade side, and improving the bearing force of the hinge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

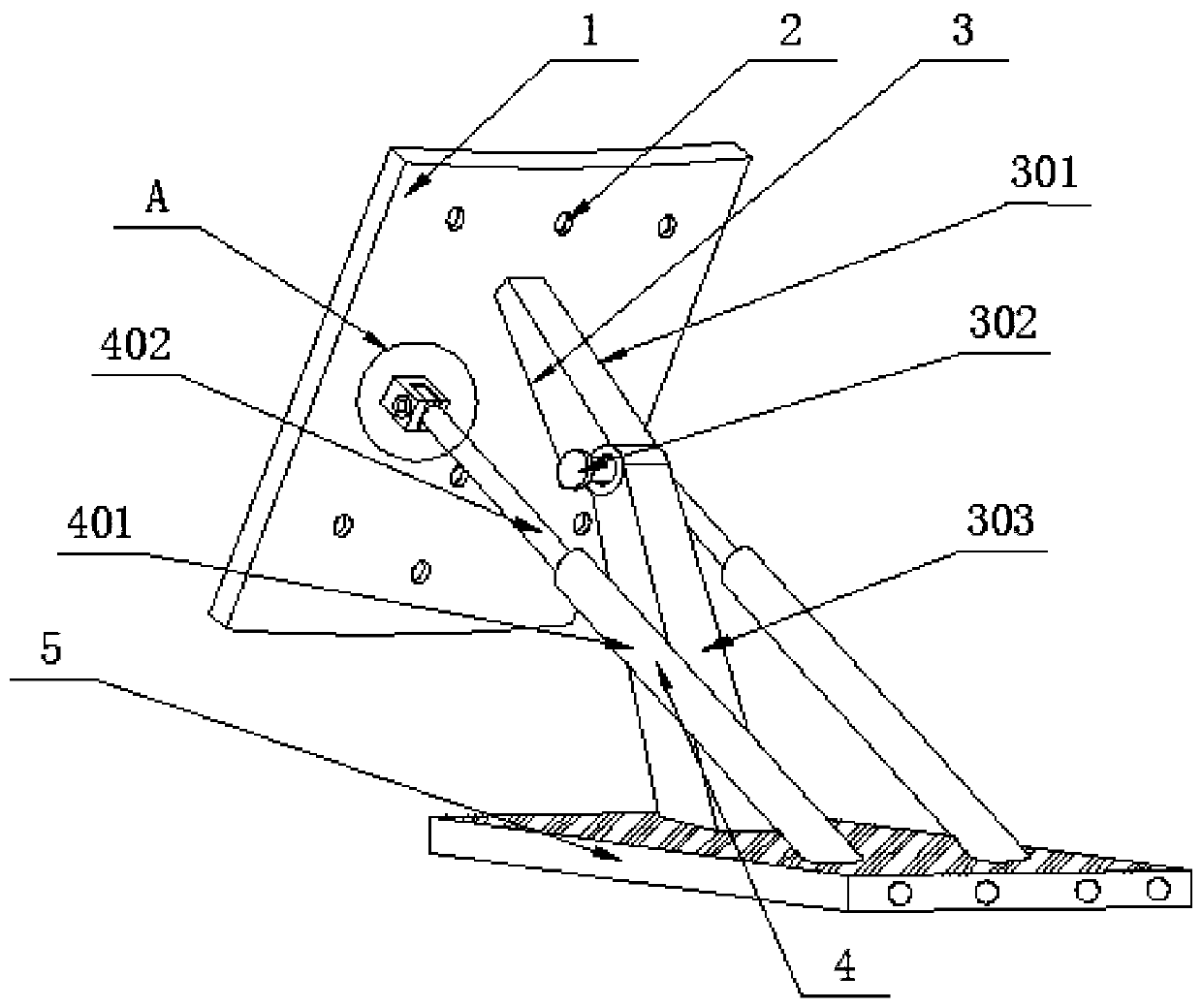

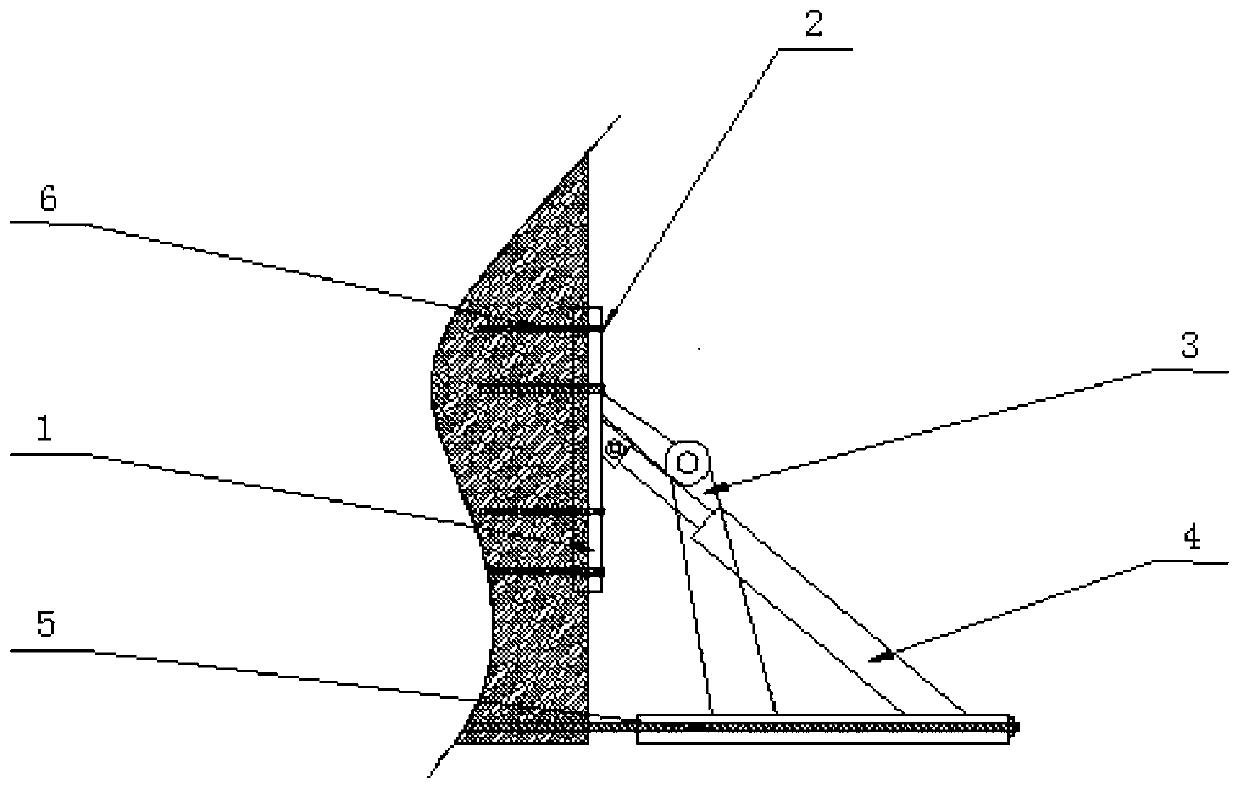

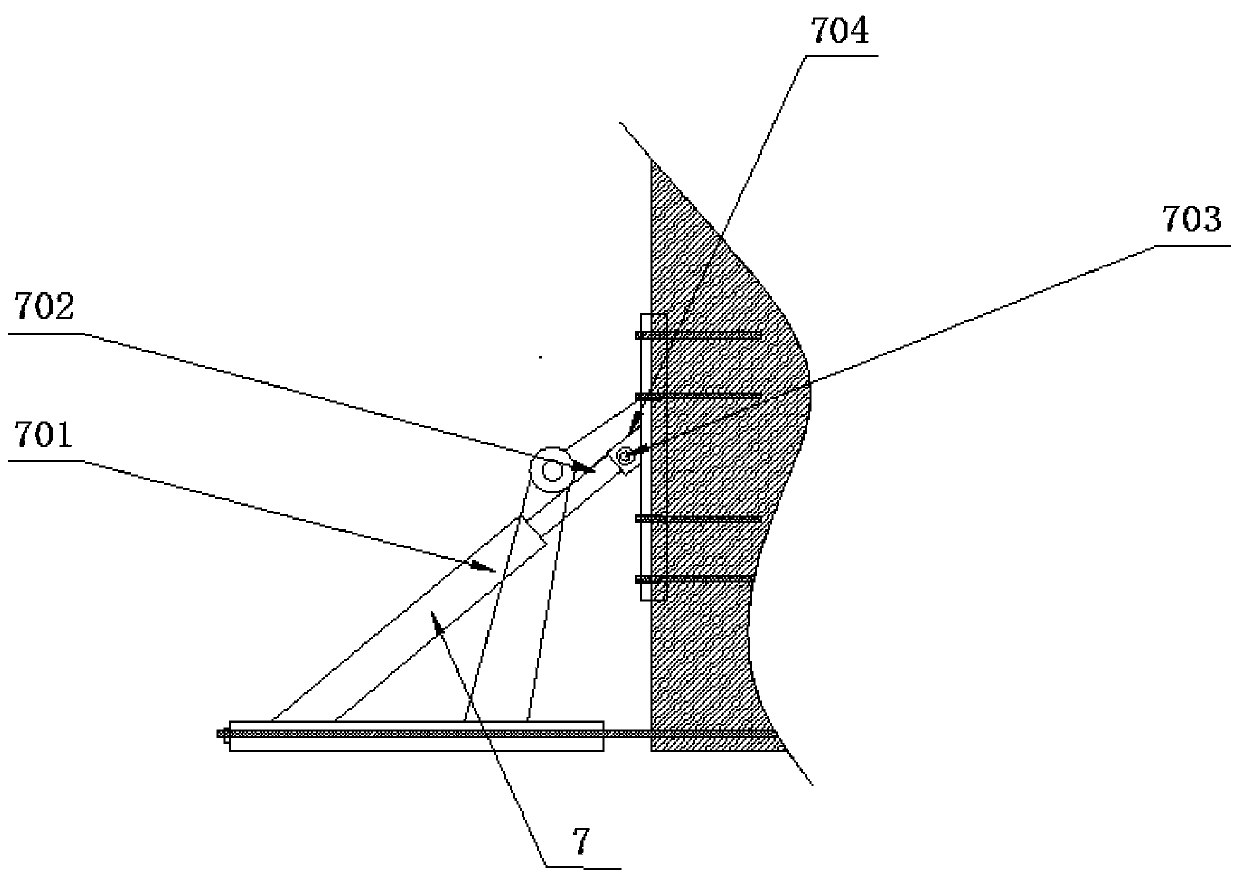

[0026] see Figure 1~6 , in an embodiment of the present invention, a non-synchronous flap side control device for an isolated island coal pillar composite coal wall, including a side side protection plate 1, a support seat 5 side side support mechanisms and a hydraulic support control mechanism, wherein the side side protection The board 1 is installed on the support seat 5 with an adjustable angle by adopting a side support mechanism, and it is characterized in that the position of the hinged connection between the side support mechanism and the side protection plate 1 adopts the hydraulic support The control mechanism is connected so that the hydraulic support control mechanism can be used to fine-tune the support angle of the apron guard plate 1 when the asynchronous apron is controlled.

[0027] In this embodiment, the hydraulic support control mechanism includes a radial hydraulic ring 406 and an axial hydraulic ring 405, wherein a hinged locking seat 404 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com