Large-roll cloth winding and unwinding machine based on circular dragging principle

A cloth and roll machine technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems that affect the appearance and quality of finished products, the gap between cloth rollers, layering and lamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

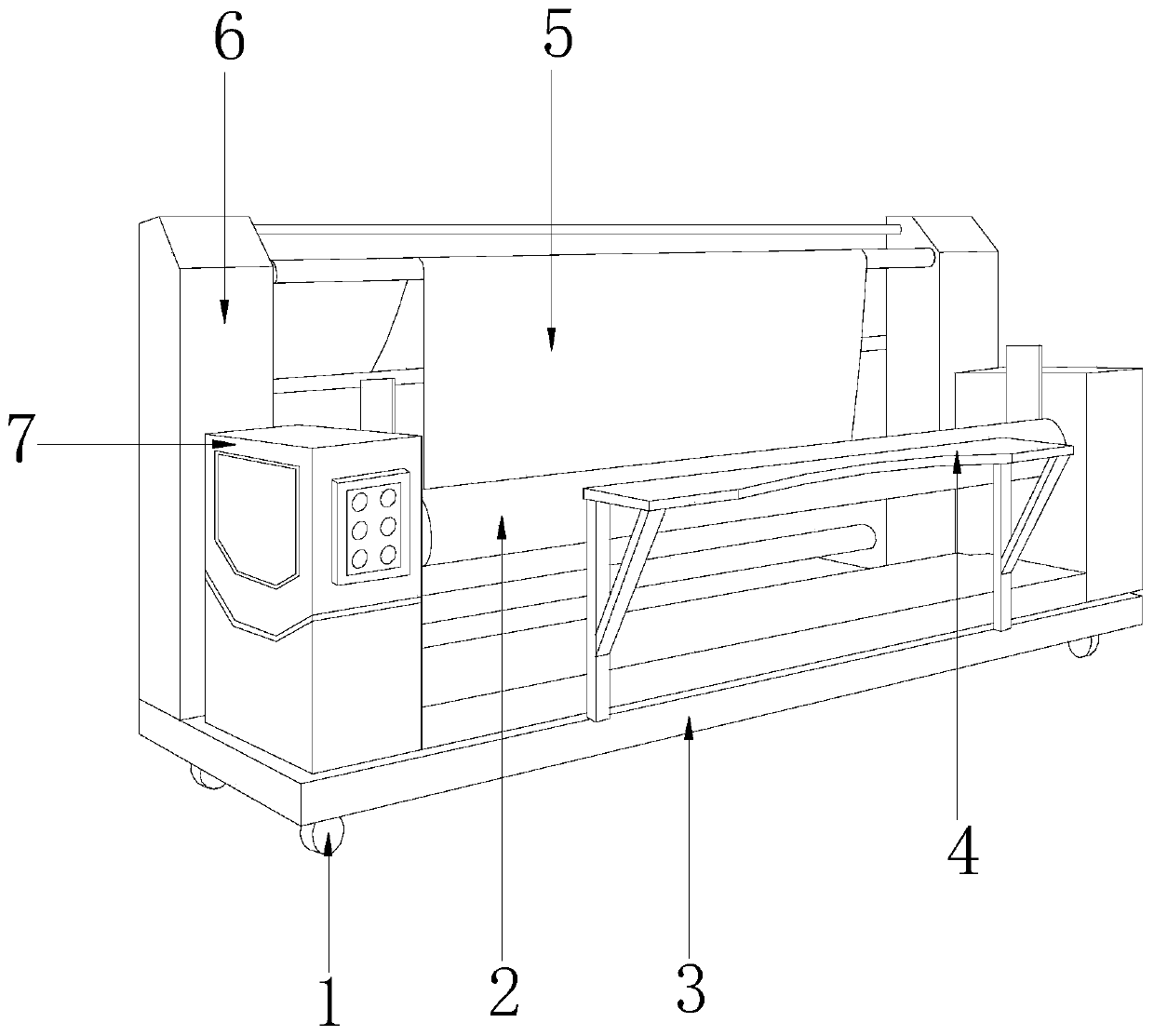

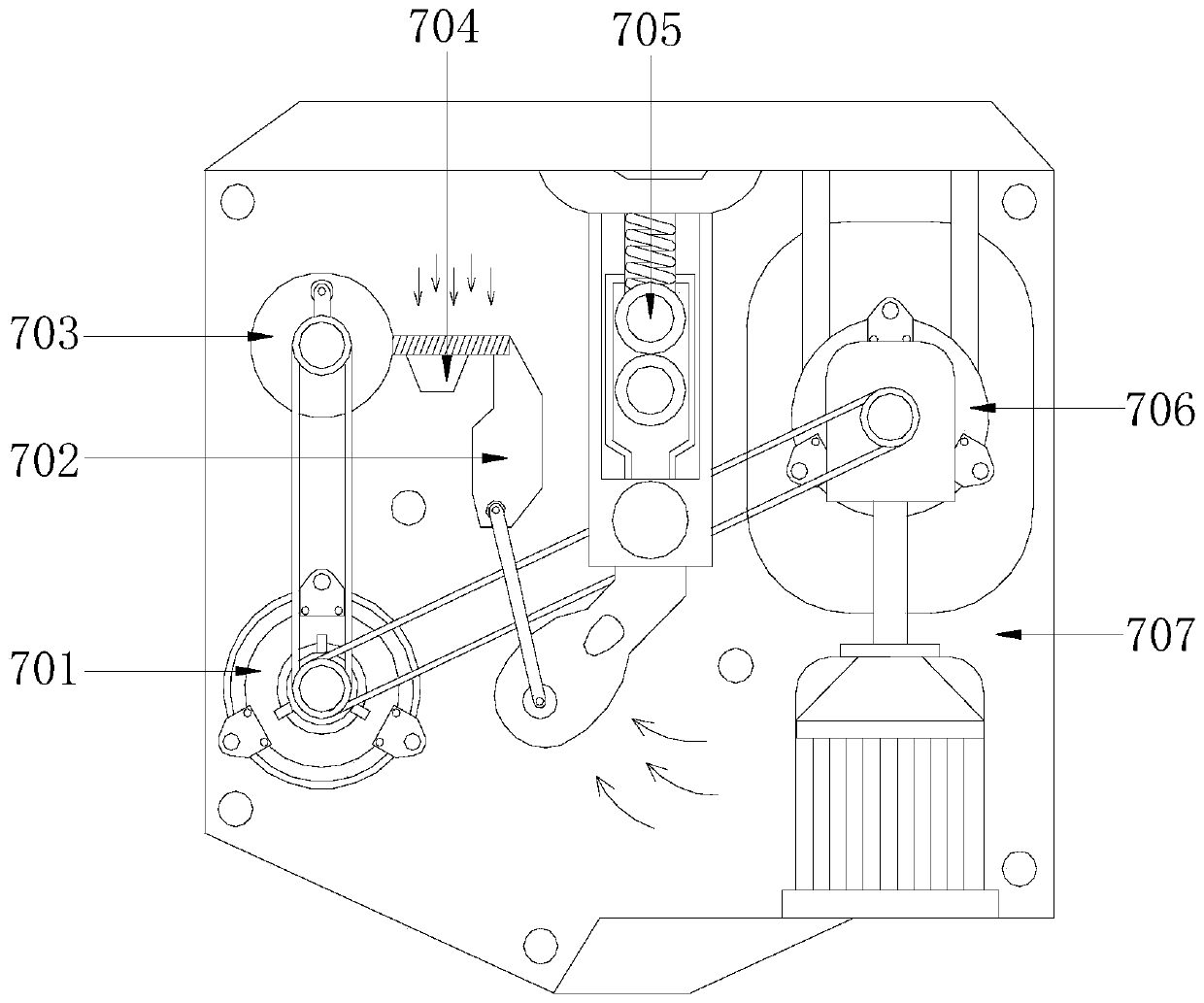

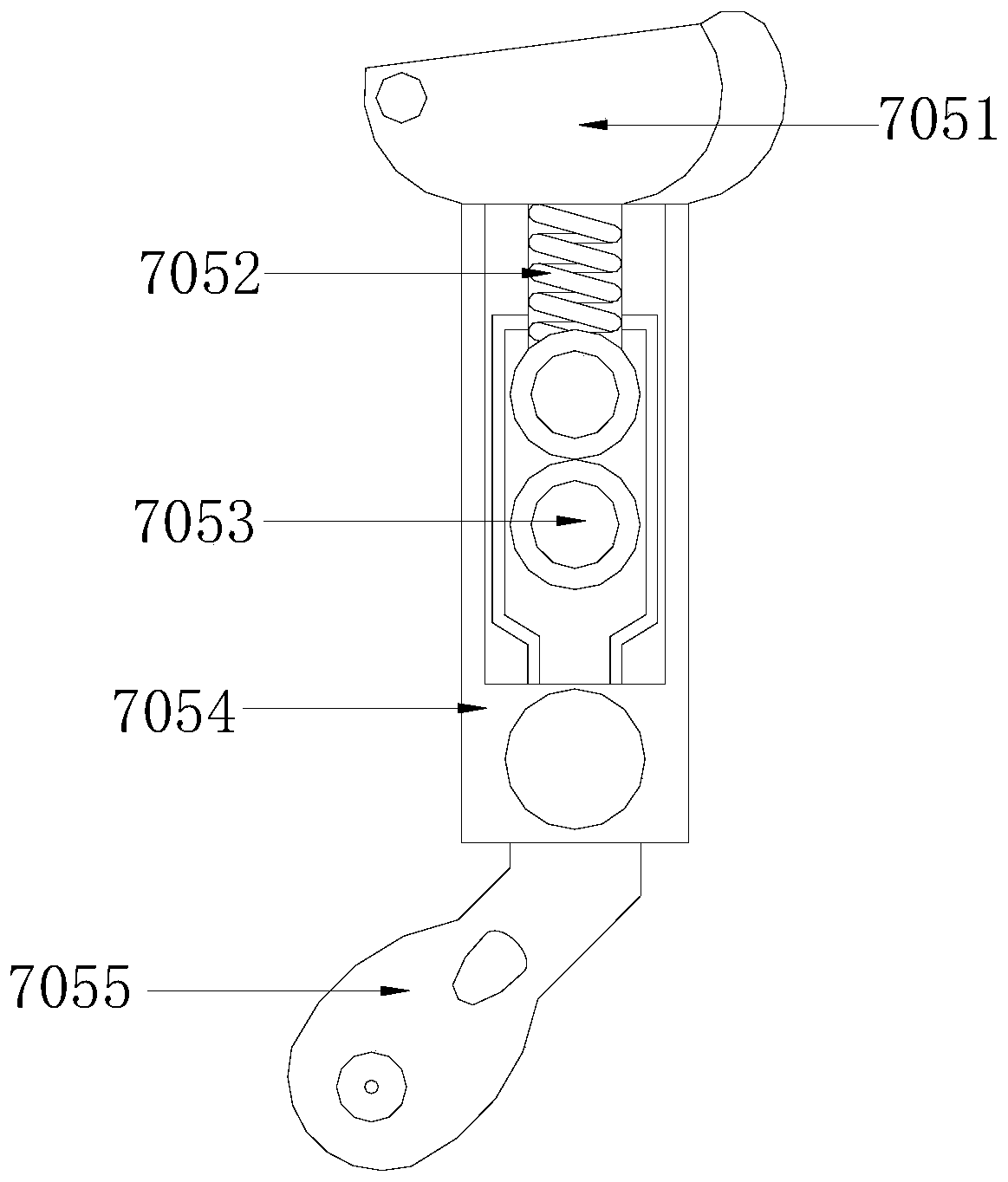

[0029] see Figure 1-Figure 6 , the present invention provides a large roll cloth unwinding and unwinding machine based on the principle of cyclic dragging, its structure includes a moving wheel 1, a roller 2, a bottom plate 3, a workbench 4, a spinning cloth 5, a vertical arm 6, and a power cabinet 7. The moving wheel 1 is provided with four, and is installed on the four corners of the base plate 3 by a buckling mode, and the vertical arm 6 is provided with two, and is installed on both ends of the surface of the base plate 3 by a buckling mode, and the two sides of the base plate 3 are provided with There is a power cabinet 7, the two ends of the roller 2 are connected through the interior of the power cabinet 7, the woven fabric 5 is connected to the roller 2, the workbench 4 is installed in the middle of the front end of the bottom plate 3 by buckling, and the power is started The roller 2 is driven to rotate behind the cabinet 7, and then the woven fabric 5 is rewound. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com