Gas flow sputtering device, target for gas flow sputtering, and manufacturing method of sputtering target raw material

A technology of airflow sputtering and manufacturing method, which is applied in the directions of sputtering coating, sputtering coating, record carrier manufacturing, etc., can solve the problem of difficult to completely eliminate particles, etc., and achieve the effect of low cost and high production efficiency

Active Publication Date: 2021-12-07

JX NIPPON MINING & METALS CO LTD

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the current mechanical pulverization and mixing method, there is a physical limit to the mi

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Login to View More

Abstract

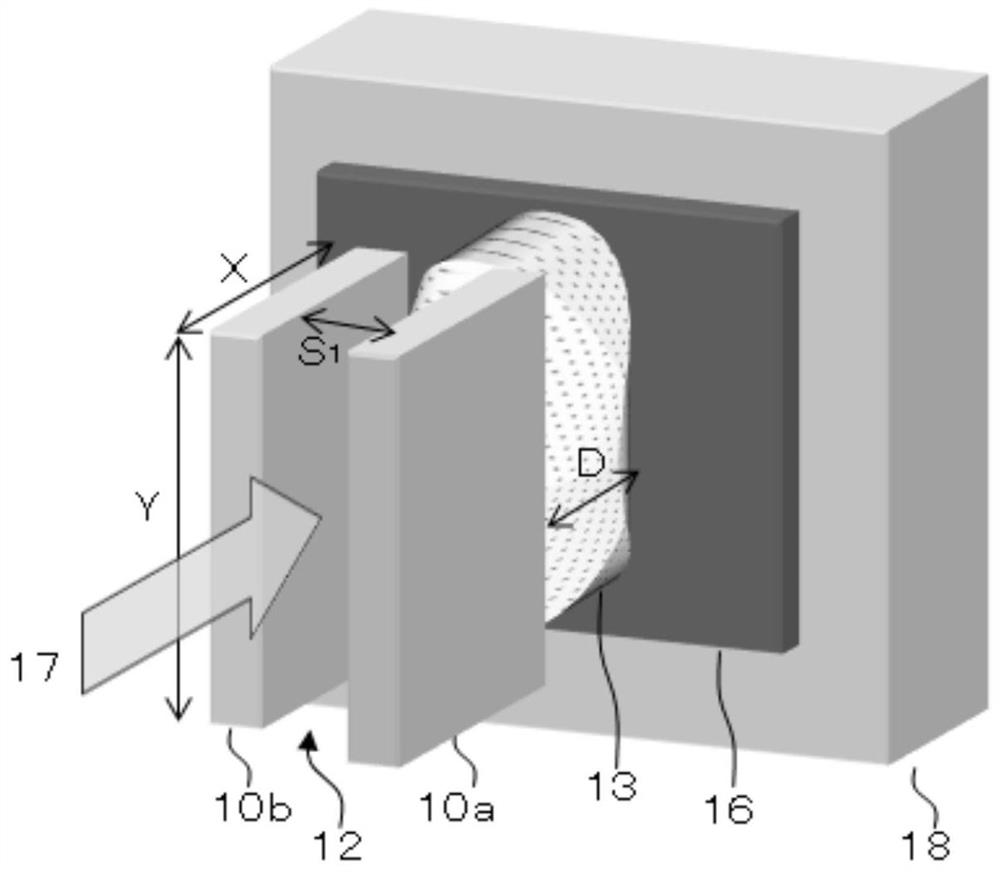

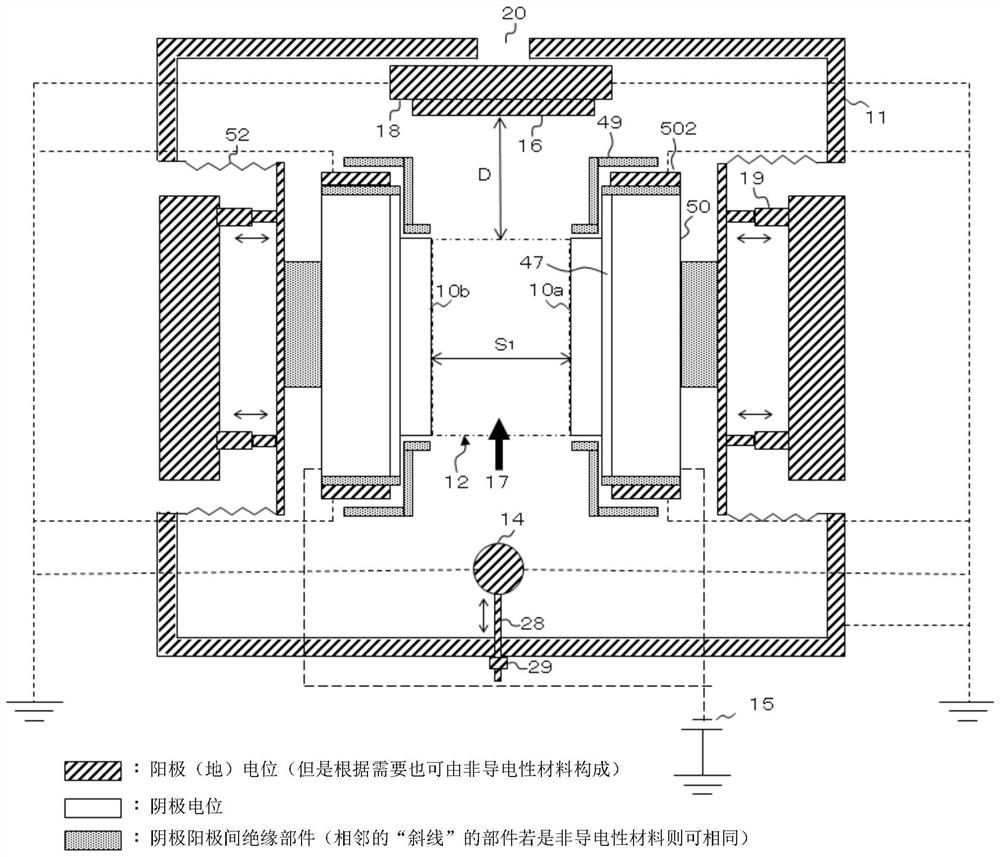

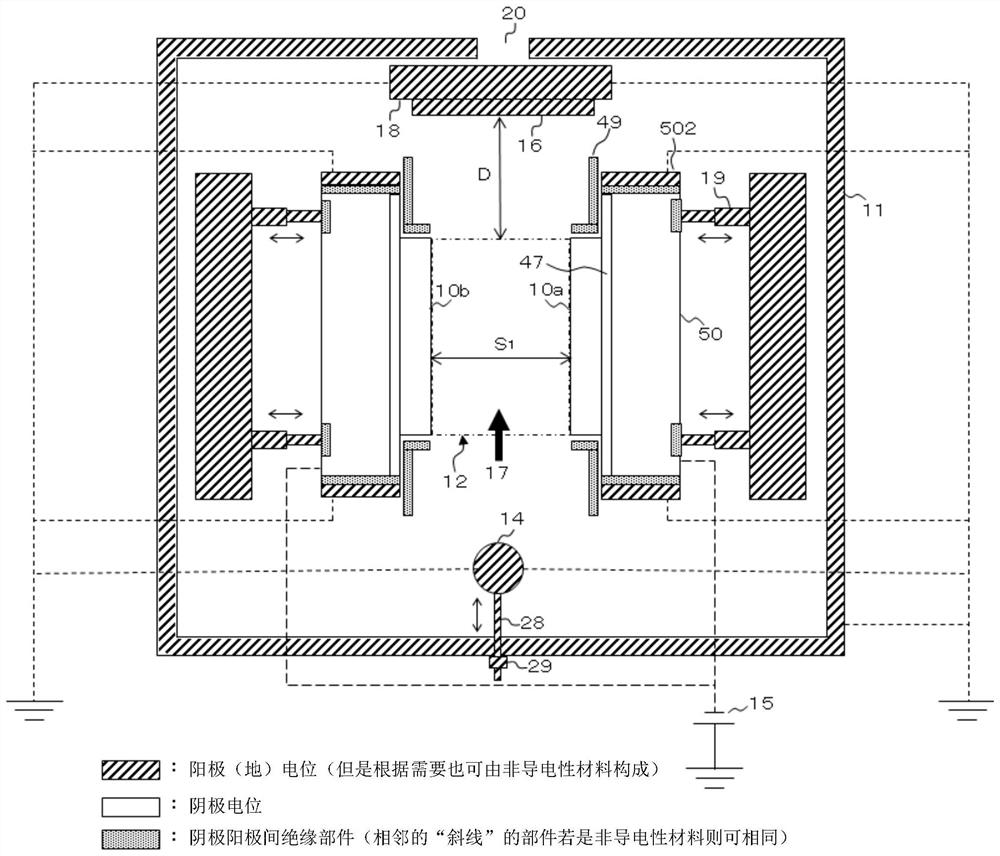

The invention provides a gas flow sputtering device suitable for manufacturing sputtering target raw materials stably and at a high sputtering rate for a long time. The gas flow sputtering device is provided with: a sputtering chamber, the inside of which can be vacuumed; a pair of flat targets arranged in the sputtering chamber with their sputtering faces facing each other at intervals; one or more gas an exhaust port for supplying sputtering gas between the pair of flat targets; an exhaust port for exhausting the sputtering gas; A space between the flat targets is disposed on a side opposite to the gas discharge port; and an interval adjustment mechanism capable of adjusting an interval between the pair of flat targets.

Description

technical field [0001] The present invention relates to a gas flow sputtering device, a target for gas flow sputtering and a method for manufacturing raw materials for the sputtering target. Background technique [0002] In the field of magnetic recording typified by hard disk drives, materials based on ferromagnetic metals Co, Fe, or Ni are used as materials for magnetic thin films responsible for recording. For example, a Co—Cr-based or Co—Cr—Pt-based ferromagnetic alloy containing Co as a main component is used for the recording layer of a hard disk employing an in-plane magnetic recording method. In the recording layer of the hard disk using the perpendicular magnetic recording method that has been put into practical use in recent years, a composite material in which nonmagnetic particles such as oxides and carbon are dispersed in a Co-Cr-Pt-based ferromagnetic alloy mainly composed of Co is used. Material. [0003] From the viewpoint of high productivity, sputtering t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C14/34G11B5/851

CPCC23C14/34G11B5/851

Inventor 小庄孝志高见英生中村祐一郎武智幹雄三上智广

Owner JX NIPPON MINING & METALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com