Continuous compaction treatment system for reinforced carbon fiber cloth wall surface

A carbon fiber cloth and treatment system technology, applied in building maintenance, construction, building construction, etc., can solve problems such as inability to construct, fail to achieve reinforcement effects, and fail to come up with effective solutions to ensure continuity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

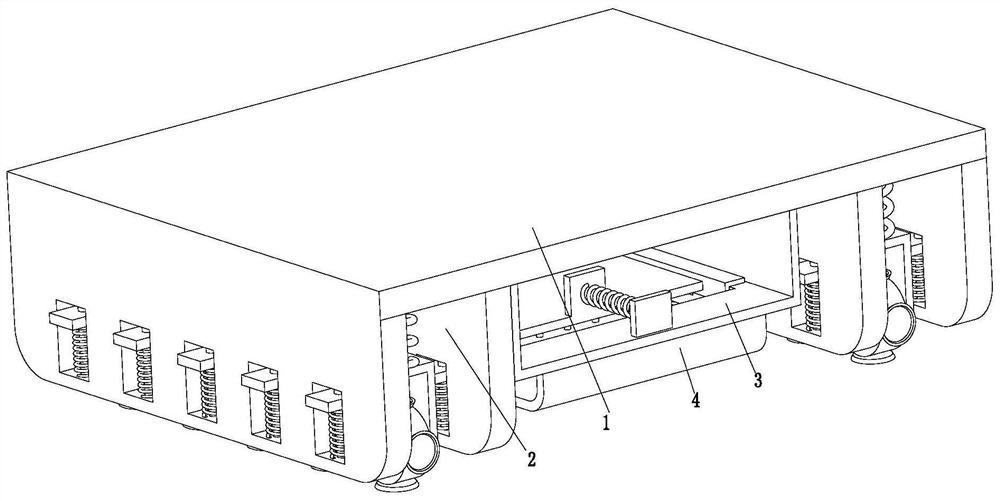

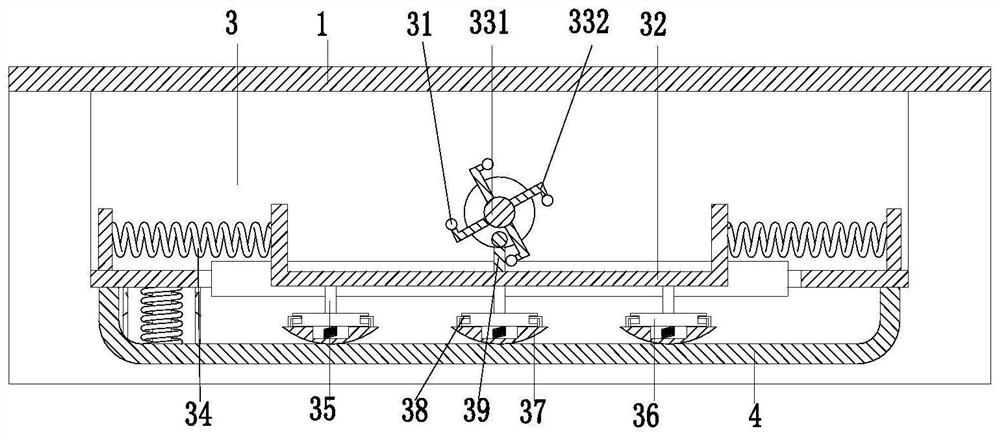

[0025] Such as Figure 1 to Figure 4 As shown, the carbon fiber cloth wall continuous compaction treatment system for strengthening buildings includes a repair support plate 1, repair supports 2 are symmetrically arranged on the left and right sides of the repair support plate 1, and a repair work frame is installed in the middle of the repair support plate 1 3. The middle part of the repair work frame 3 is provided with a repair work groove, and the lower end of the repair work frame 3 is provided with a repair rubber pad 4 .

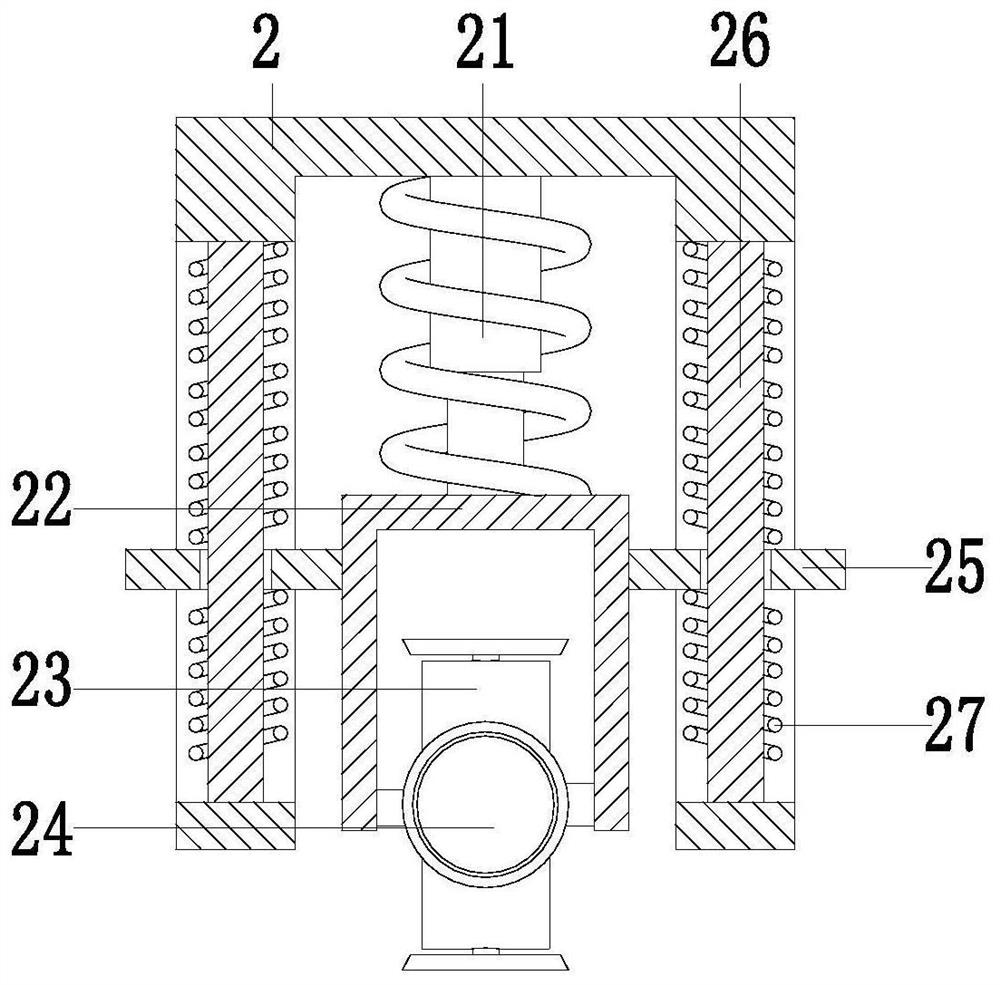

[0026] The inner wall of the repair bracket 2 is provided with elastic adjustment rods 21 at equal intervals from front to back, and an elastic attachment frame 22 is installed at the lower end of the elastic adjustment rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com