A kind of oled display panel and preparation method thereof

A display panel and substrate technology, which is applied in the field of OLED display panels, can solve the problems of backlight transmittance influence, unfavorable light output, large light loss, etc., and achieve the effects of improving color, reducing light loss, and reducing light output efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of an OLED display panel and its manufacturing method involved in the present invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0032] The invention relates to an OLED display panel, which comprises a substrate, a light-emitting layer and a color filter layer arranged on the substrate.

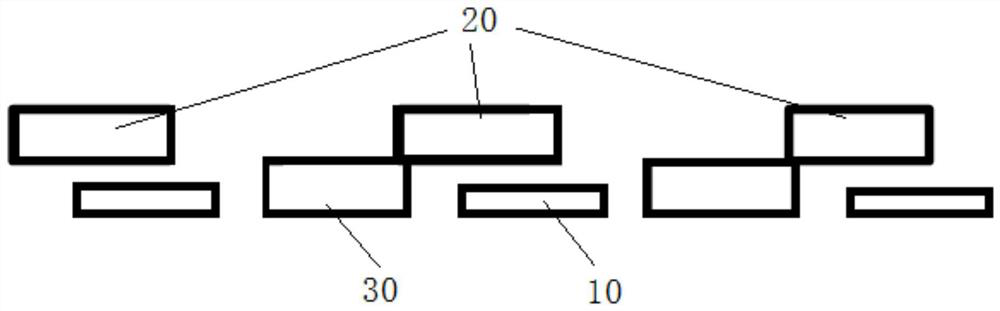

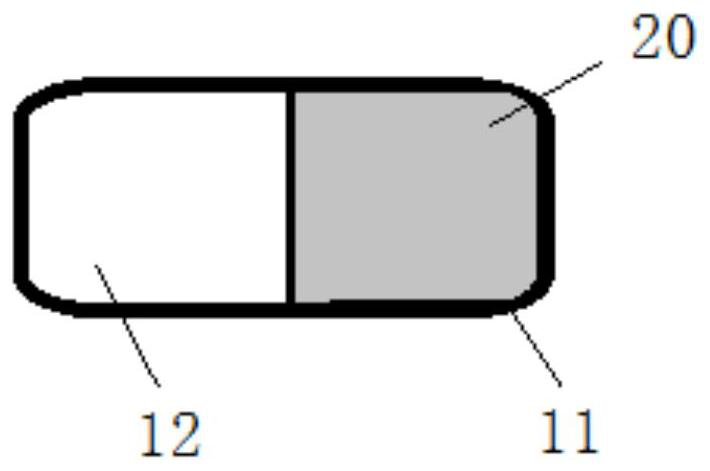

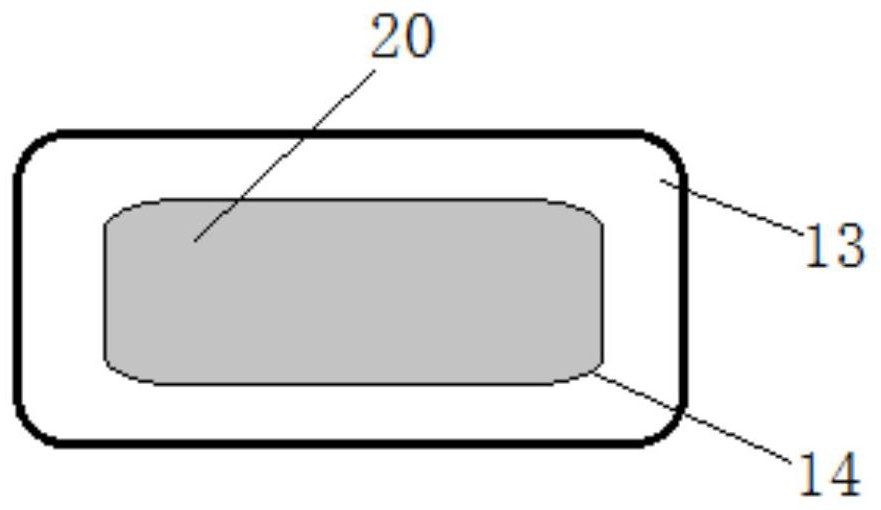

[0033] Such as figure 1 As shown, the light-emitting layer is provided with pixel units 10 arranged at intervals, and the position of the color filter layer corresponding to the pixel unit 10 is provided with a color-resist layer 20 corresponding to the color of the pixel unit. Adjacent colors A BM layer 30 is disposed between the resistance layers 20 . Wherein the thickness of the color filter layer is in the range of 0.1-10um.

[0034] Such as figure 1 As shown in , wherein at least part of the surface area of the pixel unit 10 is exposed from the corresponding color resist layer 20 disposed there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com