Novel rail system

A new track and new technology, applied in the field of rail transit, can solve the problems of low maintenance work efficiency, achieve the effect of improving maintenance work efficiency, increasing operating space, and improving construction work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

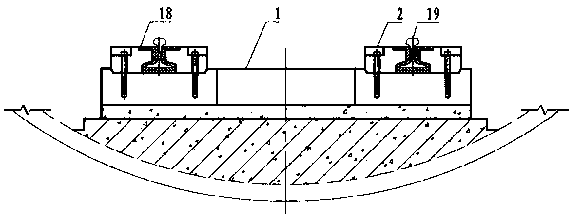

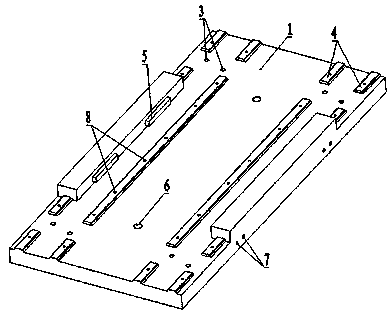

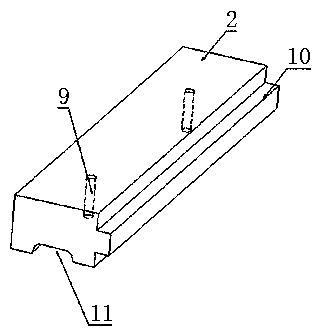

[0041] like figure 2 , 3 , 4, the assembled track slab includes a track slab main body 1 and a prefabricated rail support platform 2, and the prefabricated rail support platform 2 is detachably installed on both sides of the top of the track slab main body 1 and is formed together with the track slab main body 1 for A rail bearing groove for continuously supporting and locking the steel rail 19.

[0042] The bottom of the prefabricated rail platform 2 is provided with a prefabricated rail platform limiting groove 11, and correspondingly, the main body 1 of the track panel is provided with a protrusion 4 on the track panel.

[0043] The track plate main body 1 is provided with a prefabricated rail platform mounting hole 8, and correspondingly, the prefabricated rail platform 2 is provided with a prefabricated rail platform bolt hole 9, and the track plate main body 1 and the prefabricated rail platform 2 are connected by bolts Realize detachable connection.

[0044] The pre...

Embodiment 2

[0049] like Figure 5 , 6 As shown in , 7, the assembled track slab includes a track slab main body 1 and a prefabricated rail support platform 2. The prefabricated rail support platform 2 is detachably installed on both sides of the top of the track slab main body 1 and is jointly formed with the track slab main body 1. The rail bearing groove is used for continuous support and continuous locking of the rail.

[0050] The bottom of the prefabricated rail support platform 2 is provided with a limit protrusion 14 in the groove of the prefabricated rail support platform, and correspondingly, a groove 12 on the track plate is provided on the track plate main body 1 .

[0051] The track plate main body 1 is provided with a prefabricated rail platform mounting hole 8, and correspondingly, the prefabricated rail platform 2 is provided with a prefabricated rail platform bolt hole 9, and the track plate main body 1 and the prefabricated rail platform 2 are connected by bolts Realize...

Embodiment 3

[0056] Such as Figure 8 , 9 As shown in 10 and 10, the assembled track slab includes a track slab main body 1 and a prefabricated rail support platform 2, and the prefabricated rail support platform 2 is detachably installed on both sides of the top of the track slab main body 1 and is jointly formed with the track slab main body 1. The rail bearing groove is used for continuous support and continuous locking of the rail.

[0057] The track plate main body 1 is provided with a prefabricated rail platform mounting hole 8, and correspondingly, the prefabricated rail platform 2 is provided with a prefabricated rail platform bolt hole 9, and the track plate main body 1 and the prefabricated rail platform 2 are connected by bolts Realize detachable connection.

[0058] The steel plate 15 is pre-embedded on the main body 1 of the track slab, and the prefabricated rail support platform 2 is an integral steel channel structure or a halved steel channel structure. When the prefabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com