Tobacco harvester

A harvester and tobacco leaf technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of low harvesting efficiency, large damage to tobacco leaves, and inability to process tobacco leaves, so as to improve harvesting efficiency and reduce labor loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

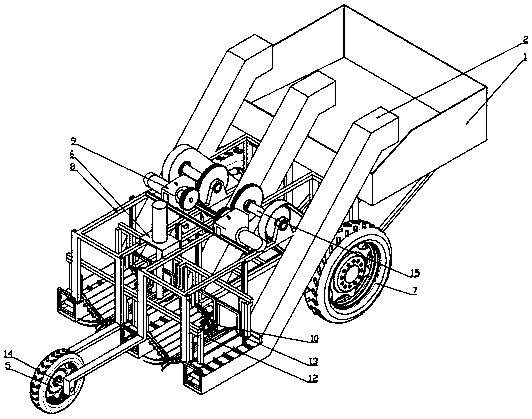

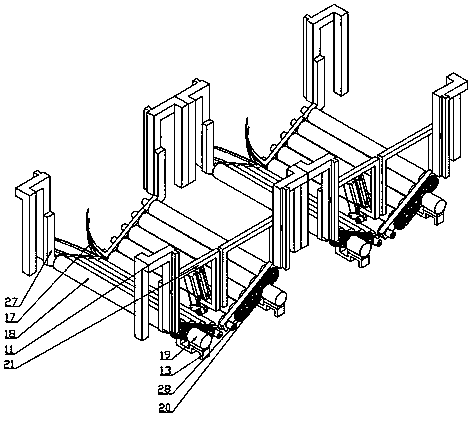

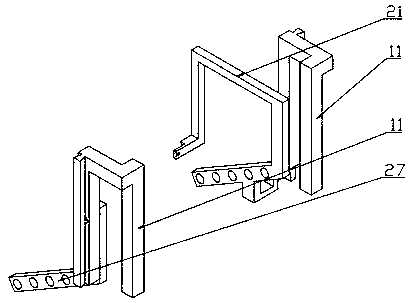

[0028] Embodiment 1: as Figure 1-10 As shown, a tobacco leaf harvester includes a vehicle frame 8, a front wheel 5, a rear wheel 7, a cargo bucket 1, a harvesting device 12, a conveying device 2, and a power unit 15;

[0029] A front wheel 5 is installed at the front end of the vehicle frame 8, and a rear wheel 7 is respectively installed on both sides of the rear end of the vehicle frame 8, and a harvesting device 12 is installed on the vehicle frame 8 between the front wheel 5 and the rear wheel 7, and the harvesting device 12 carries out tobacco harvesting. Harvest and transport to the conveying device 2, one end of the conveying device 2 is fixed on the lower side of the harvesting device 12, the other end of the conveying device 2 extends into the cargo hopper 1, and the conveying device 2 conveys the tobacco harvested by the harvesting device 12 to the cargo hopper 1, The cargo bucket 1 is installed at the tail end of the vehicle frame 8, and the bottom of the cargo buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com