Process equipment for sealing and curing impregnated liquid filler of motor armature

A technology of process equipment and dipping process is applied in the field of process equipment for sealing and curing after liquid filler dipping process. , the effect of delaying the aging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

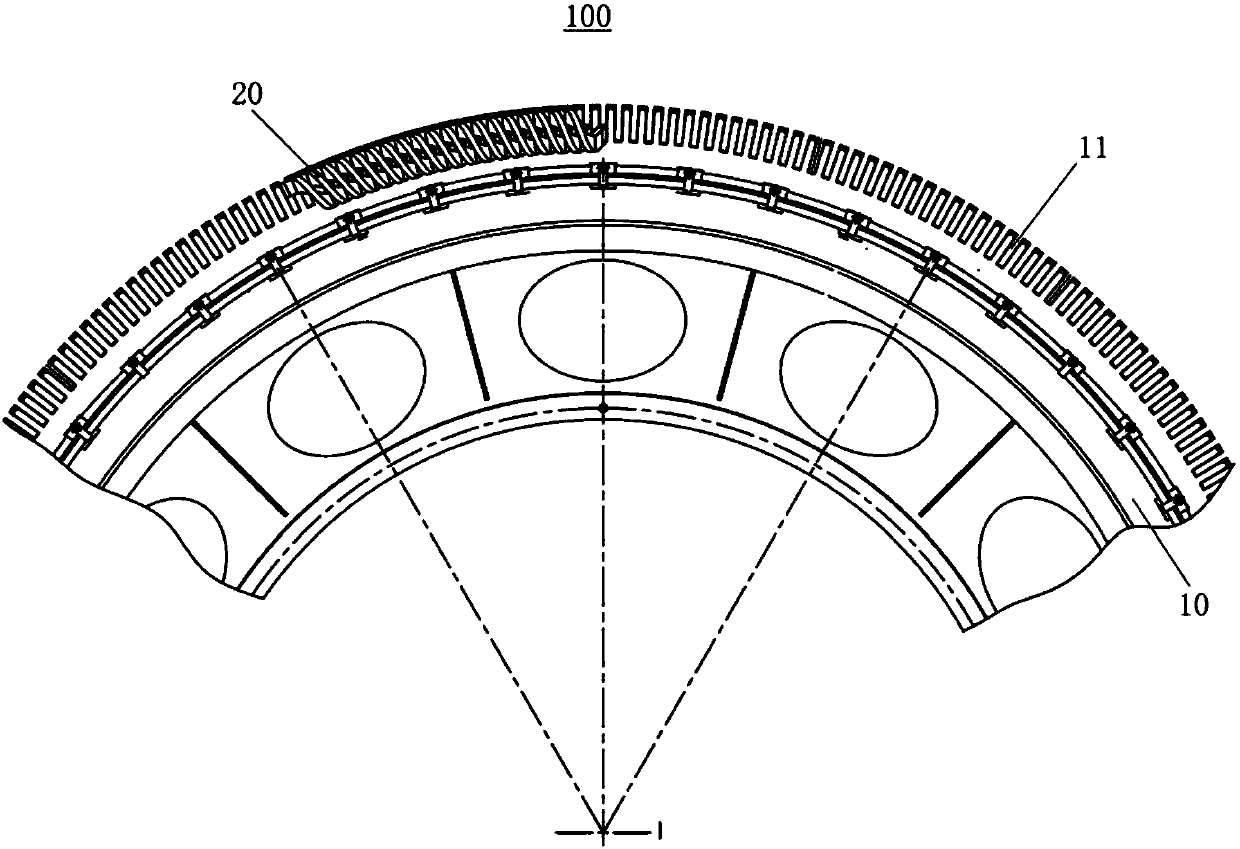

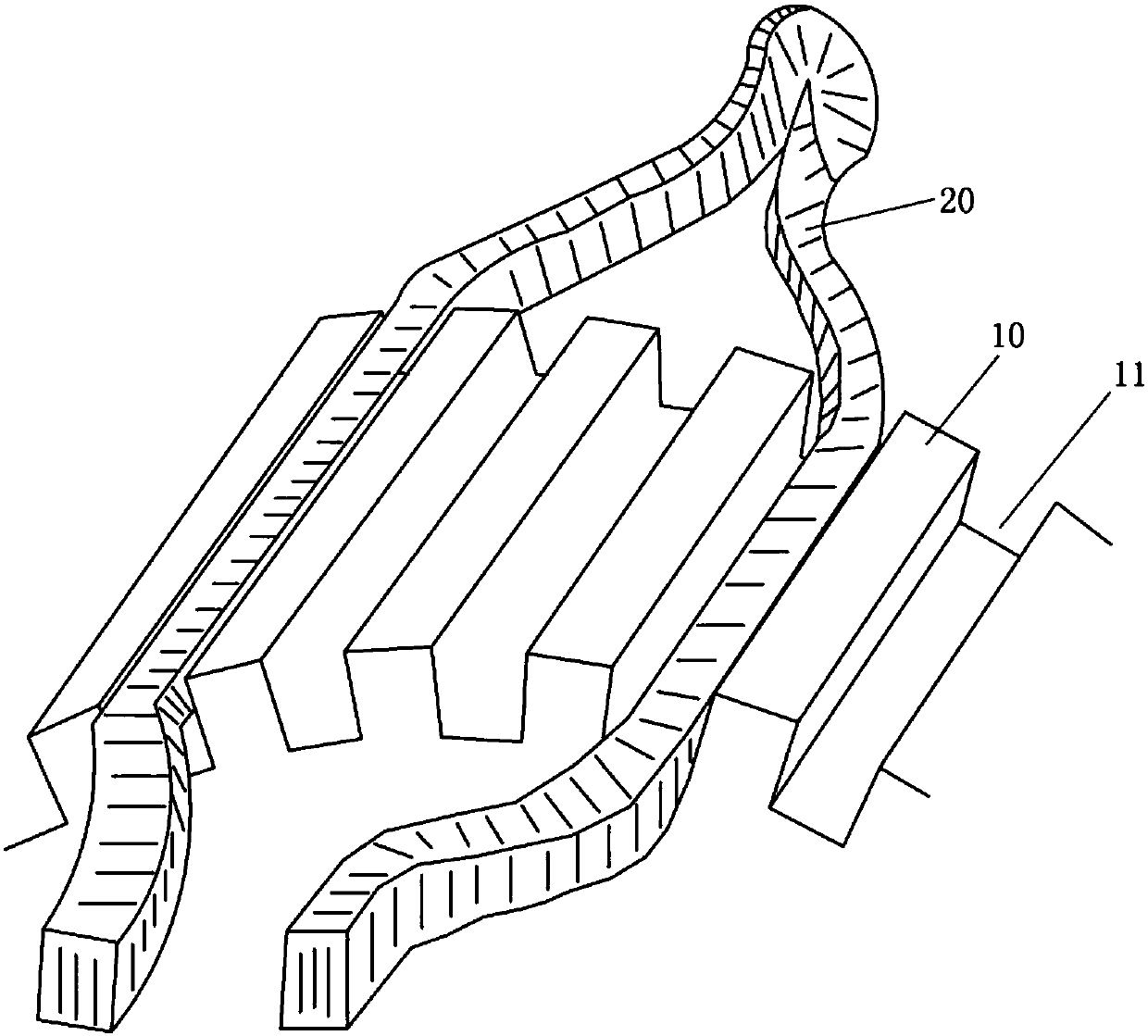

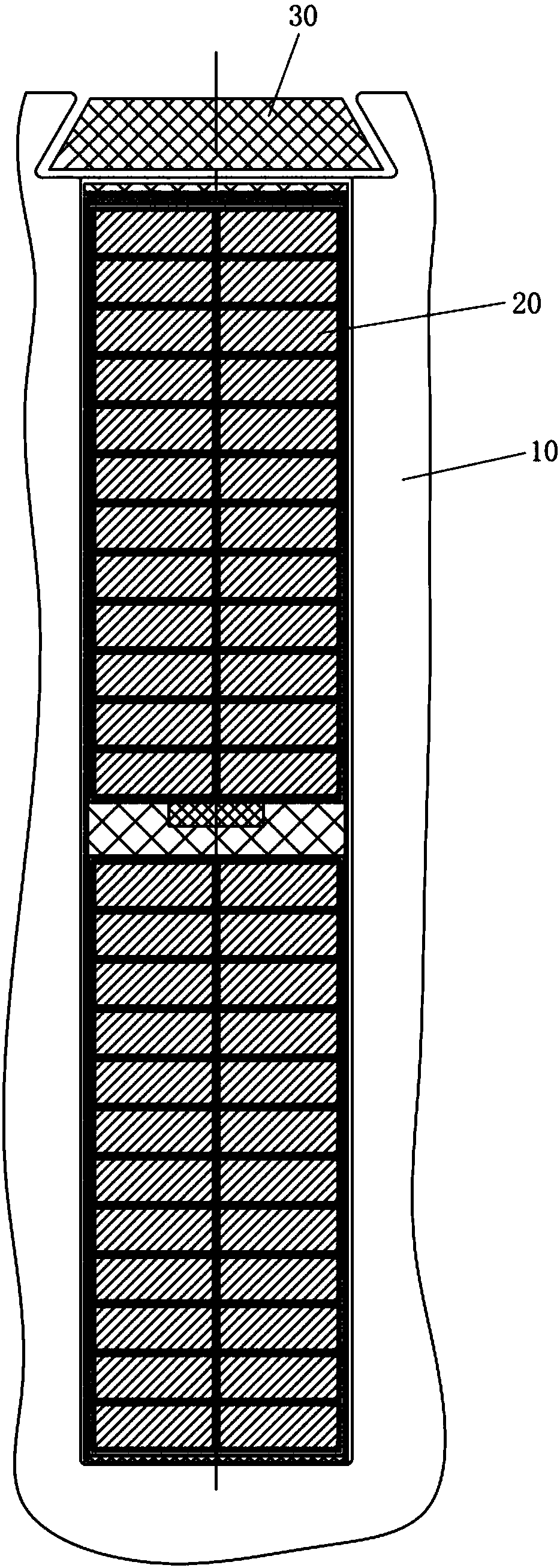

[0057] Embodiments of the present invention provide a process equipment for suppressing the outflow of liquid filler in the cylindrical radially porous rotary structure component and enhancing the solidification of the liquid filler. According to the solution of the embodiment of the present invention, after the motor armature (including various organizational parts of the magnetic conductive part and the coil winding) is impregnated with the liquid filling material, it is axially and horizontally placed in the process equipment for rotary baking, and the motor armature A high-pressure airflow is formed between the hub and the air junction area, between the slot wedge and the radial gap of the magnetic permeable part and the air junction area, and the applied high-pressure airflow can overcome the centrifugal force of the liquid filling material by gravity and the rotary baking method. Pressure sealing is carried out to build a sealing protection system to prevent the excessive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com