Automobile visual field check method

A verification and automotive technology, applied in the field of automotive vision verification, can solve the problems of increasing verification workload, complex drawing of three-dimensional vehicle models, and increasing the difficulty of manual verification, so as to improve test accuracy and accurate determination, and reduce manual verification. The effect of nuclear workload and drawing process is fast and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

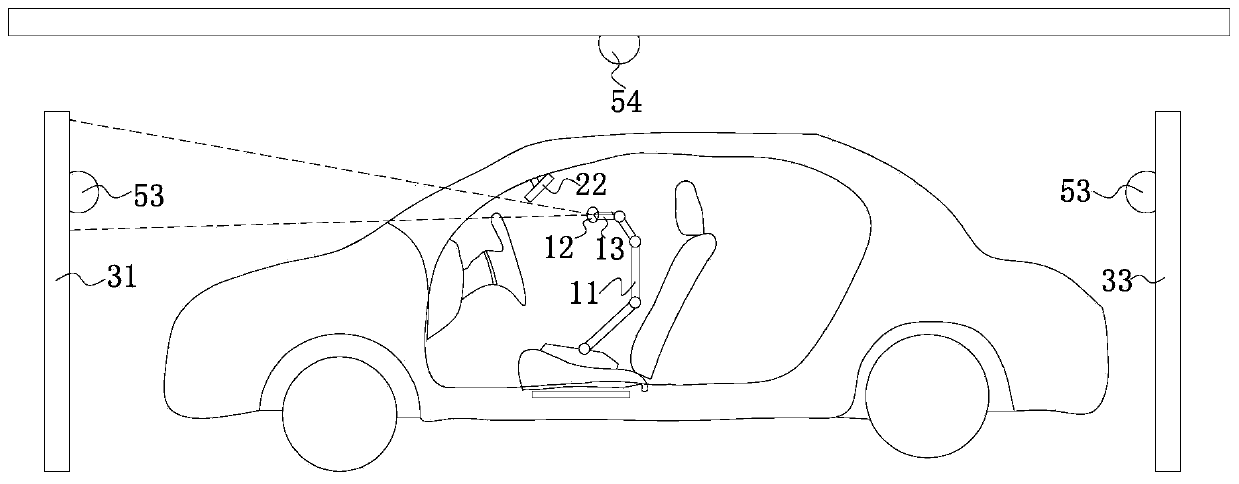

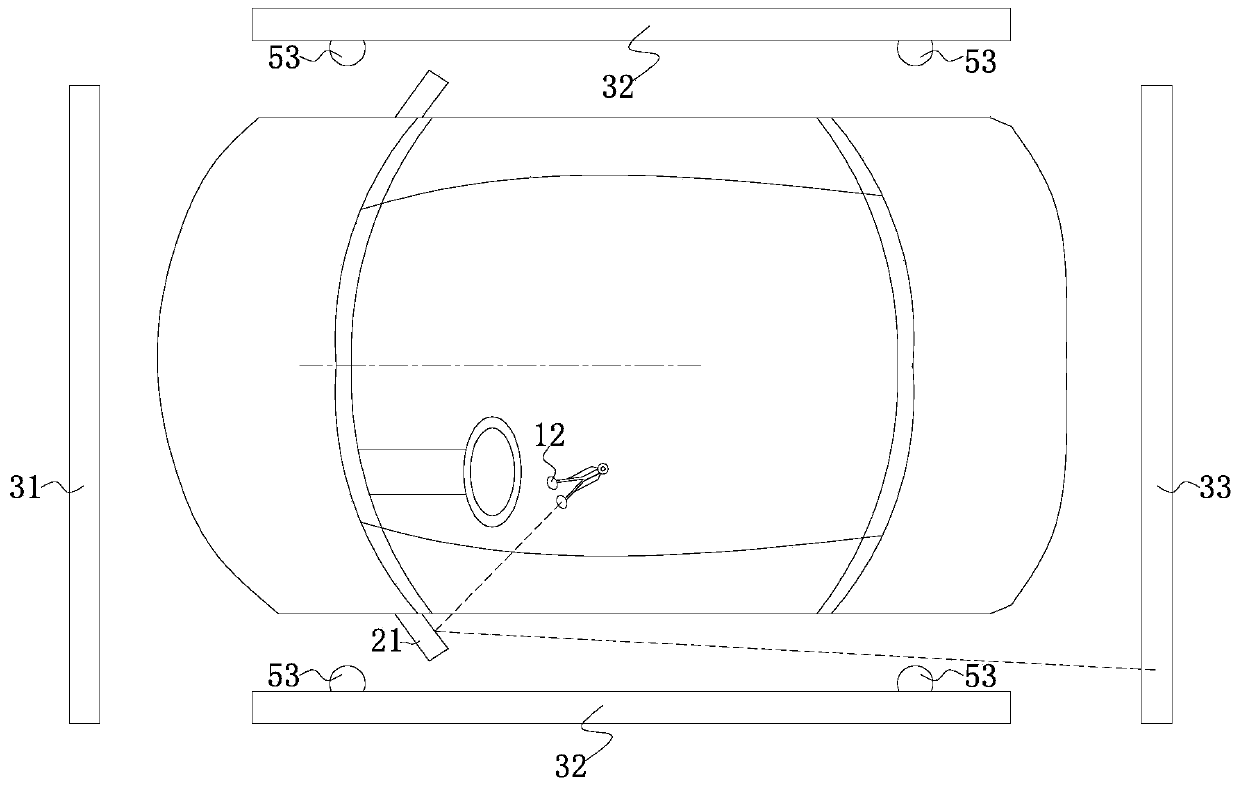

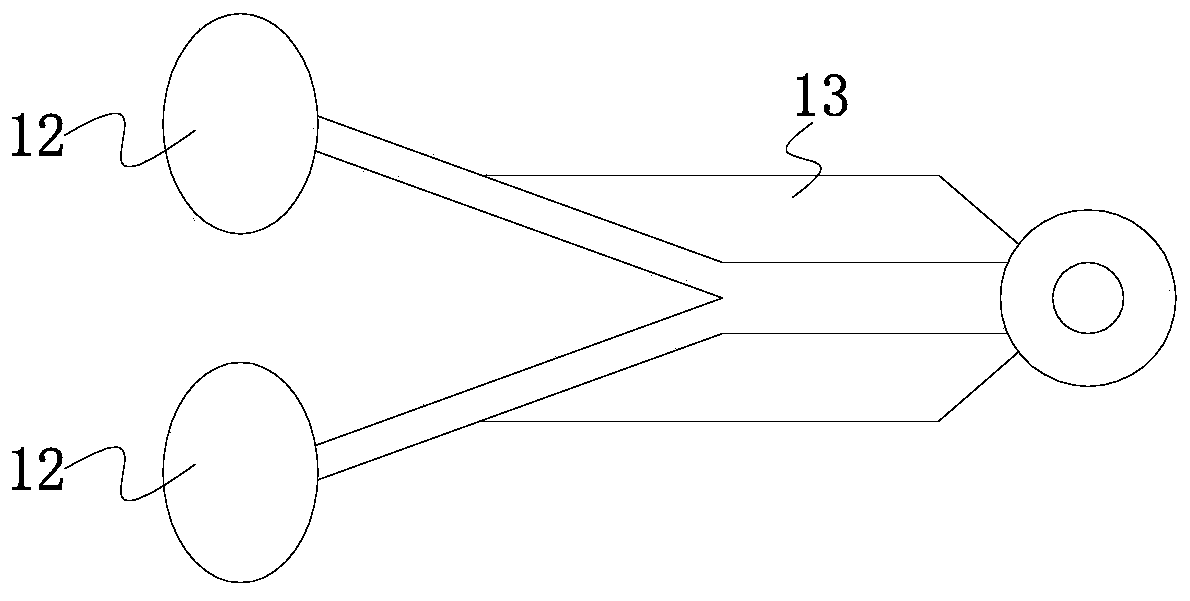

[0039] Such as Figure 1-Figure 8 A kind of car field of view calibration method shown comprises the car to be tested, and the driver's seat in the car to be tested is provided with a fixed bracket, and the fixed bracket can have clips at the bottom, and the clips are clamped with the surface of the seat, and the fixed bracket is also It can be formed by lapping multiple steel pipes, and the bottom of the steel pipes is directly connected to the slide rail at the bottom of the seat through bolts; the fixed bracket is provided with a multi-axis manipulator 11 that can move along the longitudinal, horizontal and vertical directions of the car, and generally a five-axis manipulator can be used. Or a six-axis manipulator, a four-axis manipulator can also be set on a slide rail; the end of the upper end of the manipulator 11 is equipped with a horizontally arranged gripper 13;

[0040] The gripper 13 can rotate around the vertical axis passing through its own center point, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com