Non-feeling full-welt seamless underpants

A technology of welt and underwear, applied in underwear, baby underwear, clothing, etc., to reduce friction and tightness, increase comfort, and improve comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

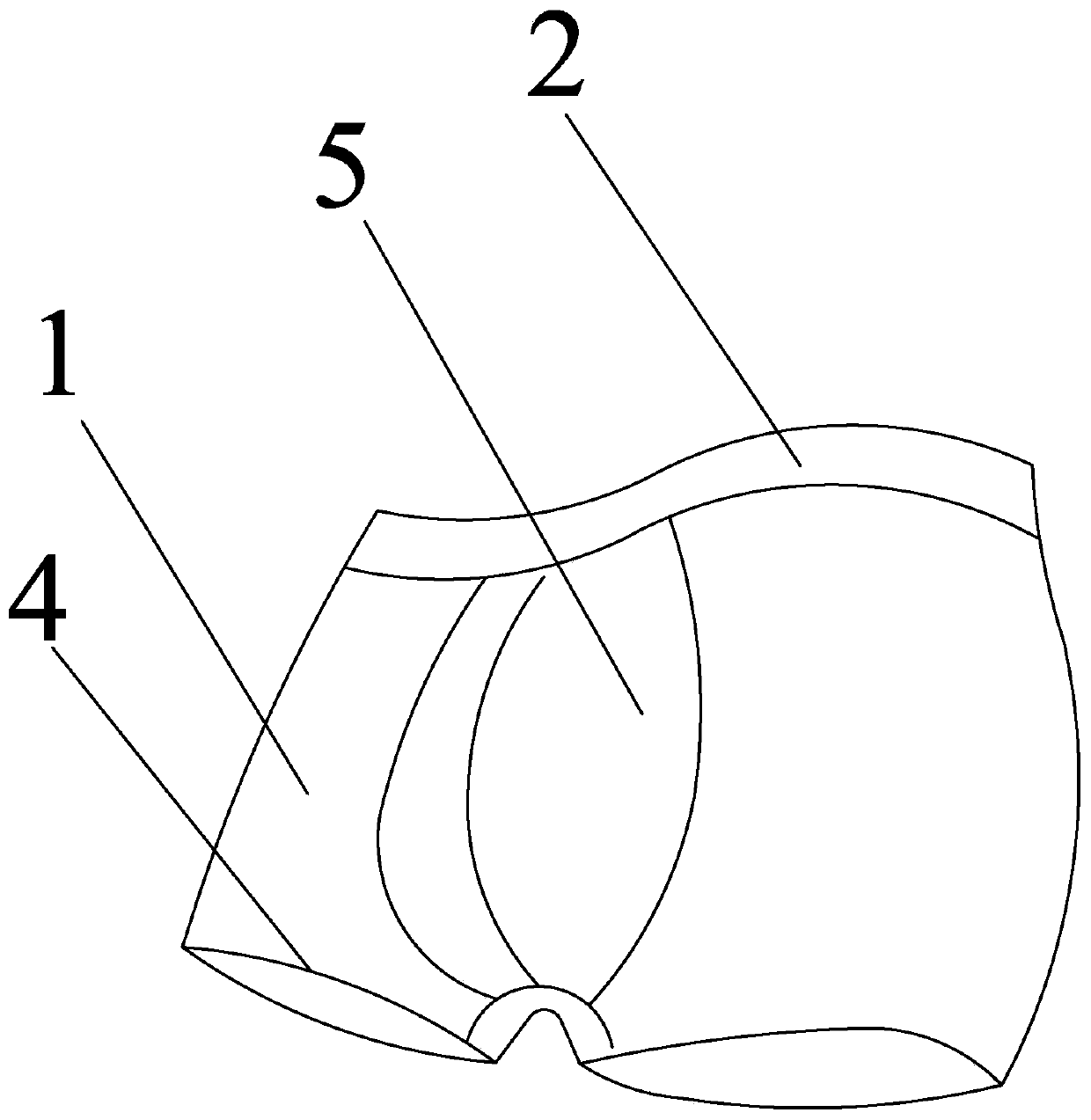

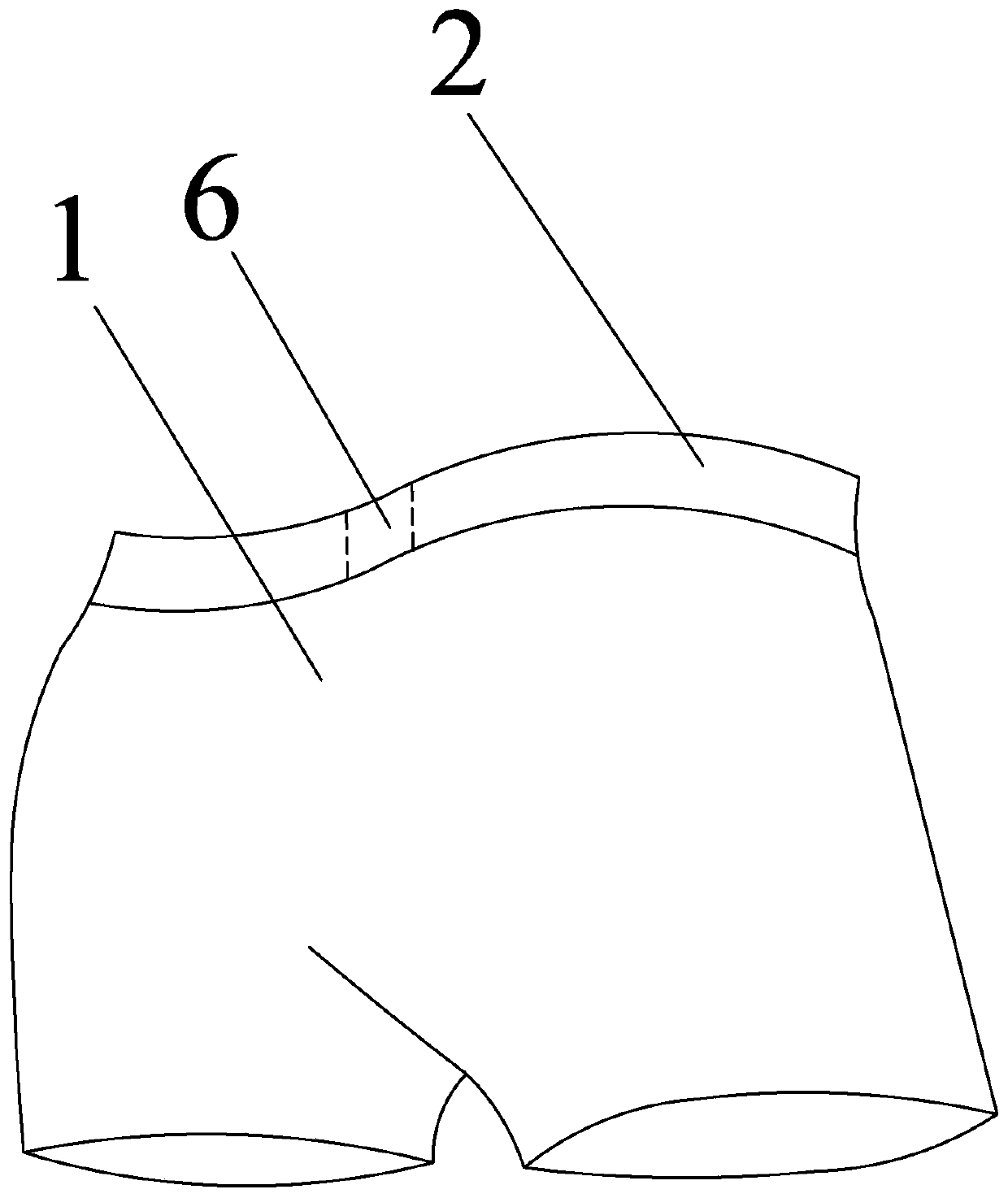

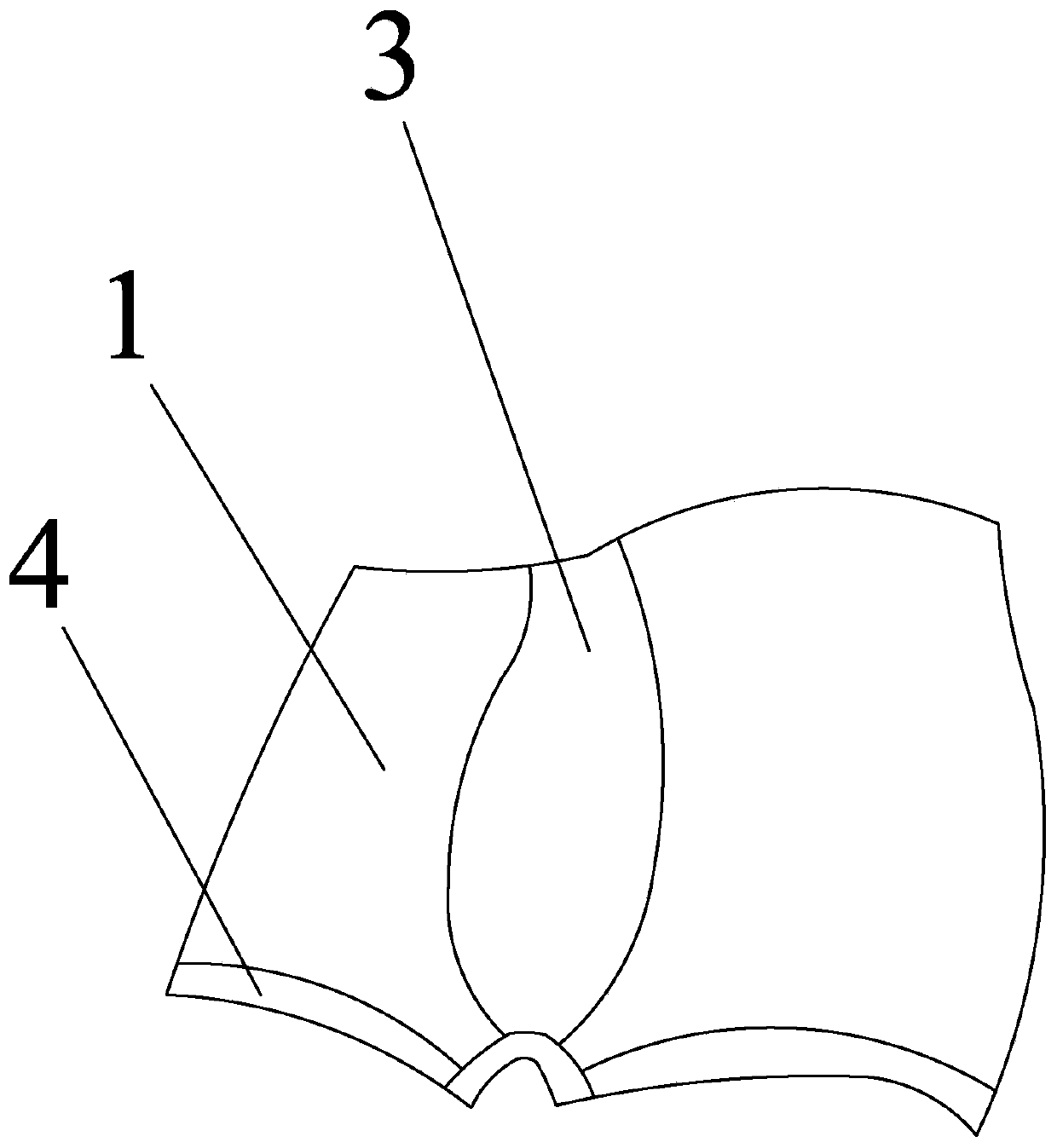

[0012] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a kind of non-sensing all-welt exposed rib underwear described in this embodiment is characterized in that it includes a trouser body 1, an exposed rib waistband 2, a trouser body inner crotch 3, a trouser body front center 5, Shaping sand layer 6 and two trouser legs 4;

[0013] The trousers body 1 is integrally made of a whole piece of fabric, and the open rib waistband 2 is set at the waist of the trouser body 1, and the inner surface of the open rib waistband 2 is all covered by the outer surface of the trouser body fabric 1 through bonding, and the trouser body The inner crotch 3 is arranged on the front middle part of the inner surface of the trouser body 1, and the upper end of the trouser body inner crotch 3 extends to the edge of the trouser waist, and the upper end of the trouser body inner crotch 3 is attached to the inner surface of the trouser waist, and the trouser bo...

specific Embodiment approach 2

[0015] Specific implementation mode two: combination image 3 This embodiment is described. In this embodiment, the inner crotch 3 of the trouser body is a mesh breathable weaving structure, and other components and connection methods are the same as those in the first embodiment.

[0016] In this way, the mesh breathable weaving structure has multiple functions such as moisture absorption, breathability, comfort, heat dissipation, mildew resistance, bacteriostasis, UV protection, quick drying, and sound absorption. , more breathable.

specific Embodiment approach 3

[0017] Embodiment 3: In this embodiment, a non-inductive label is printed on the inner surface of the trouser body 1 , and other components and connection methods are the same as in Embodiment 2.

[0018] In this way, many existing underwear labels are arranged on the inner waist of the trousers body 1 through sewing technology, but the present invention adopts the non-inductive full-fitting technology, abandons the traditional label setting method, and uses printing instead. The label is printed on the inner side of the trouser body, so that the user will not have more touch and friction when wearing it, which further increases the comfort.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com