A crawler-type remote mine-sweeping system

A crawler-type, pattern-based technology, applied in the direction of offensive equipment, defense devices, etc., can solve the problem of single function of mine-sweeping vehicles and inability to meet the requirements of mine-sweeping operations in various situations at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

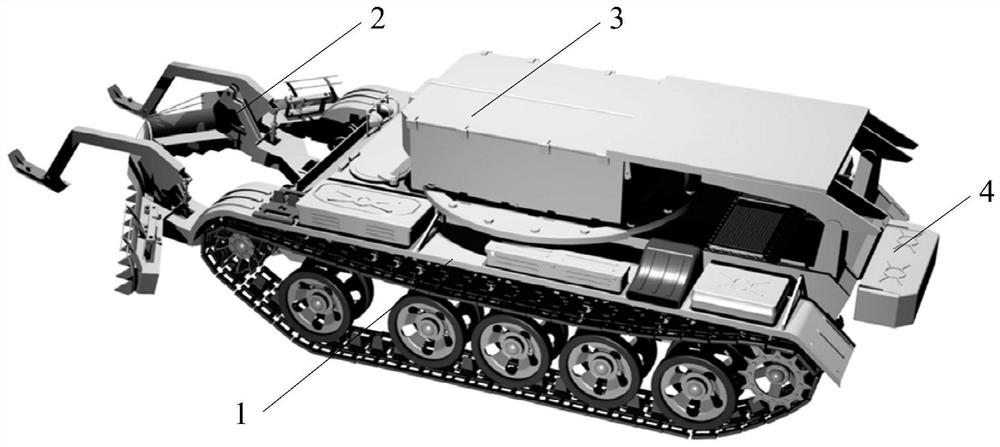

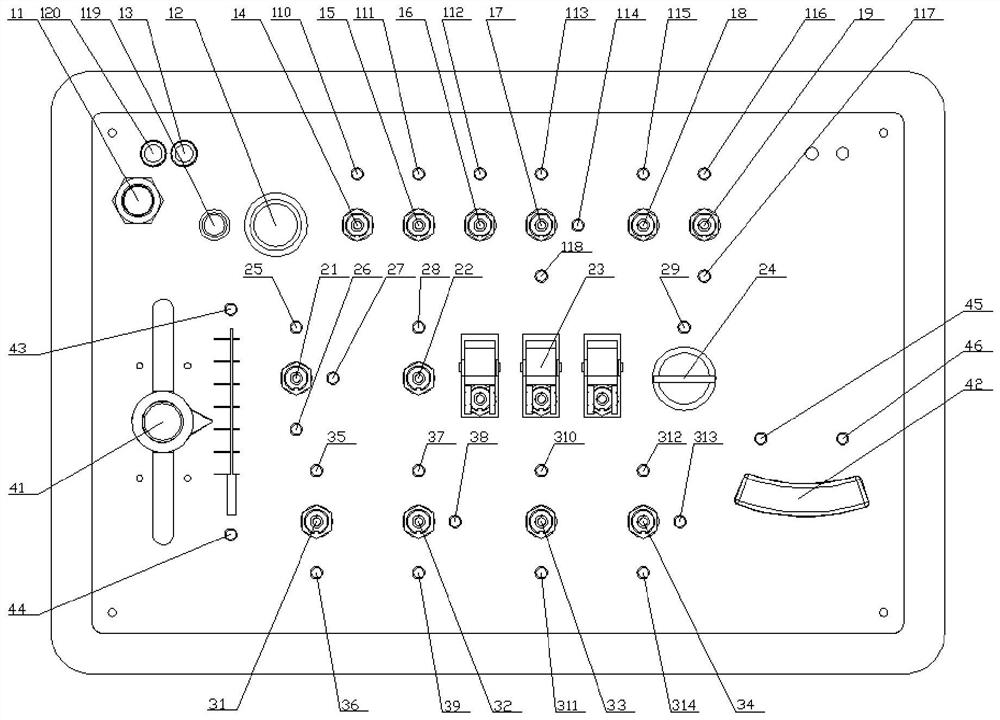

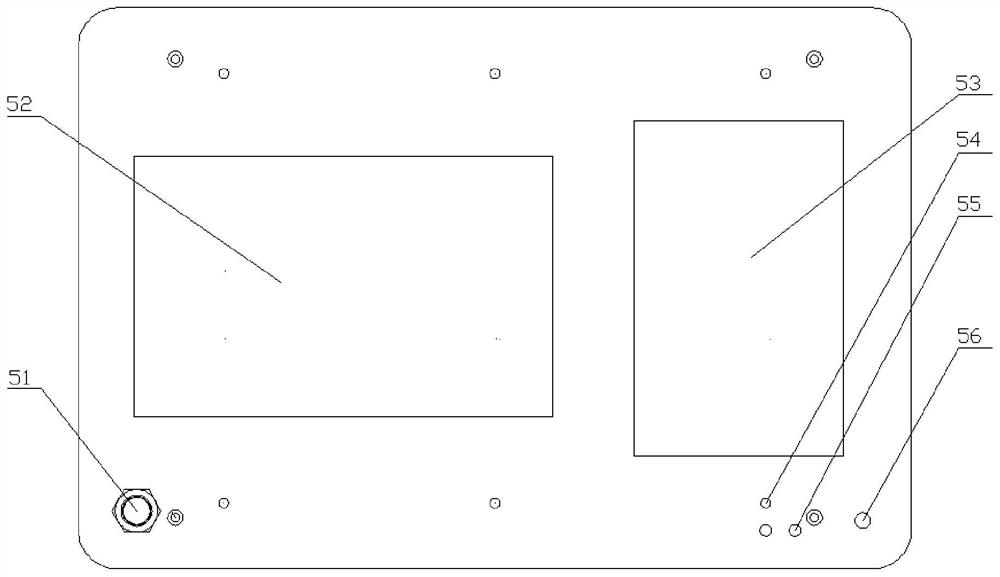

[0031] This embodiment provides a crawler-type remote mine-sweeping system, such as Figure 1 to Figure 5 As shown, it includes a tank chassis 1, a top-loading operation device, and a remote control device for controlling the tank chassis 1 and the top-loading operation device. 3. Passage marking unit 4, working hydraulic unit and working electric control unit, the minesweeping plow 2 is set at the front end of the tank chassis 1, the blasting and minesweeping unit 3 is set at the top of the tank chassis 1, and the passage marking unit 4 is set at the rear of the tank chassis 1 At the end, the working hydraulic unit is used to provide power for the minesweeping plow 2, the blasting minesweeping unit 3 and the passage marking unit 4, and the operation electronic control unit is used to control the actions of the minesweeping plow 2, the blasting minesweeping unit 3 and the passage marking unit 4.

[0032]Exemplarily, the tank chassis 1 is sequentially divided into a cockpit, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com