Locomotive unit brake demounting, mounting and transferring mechanism

A technology for brakes and locomotives, applied in the direction of transportation of passenger cars, hoisting devices, transportation and packaging, etc., can solve the problems of waste of personnel in the maintenance warehouse, physical injury of operators, and narrow operating space, and achieves reduction of labor intensity, improvement of work efficiency, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

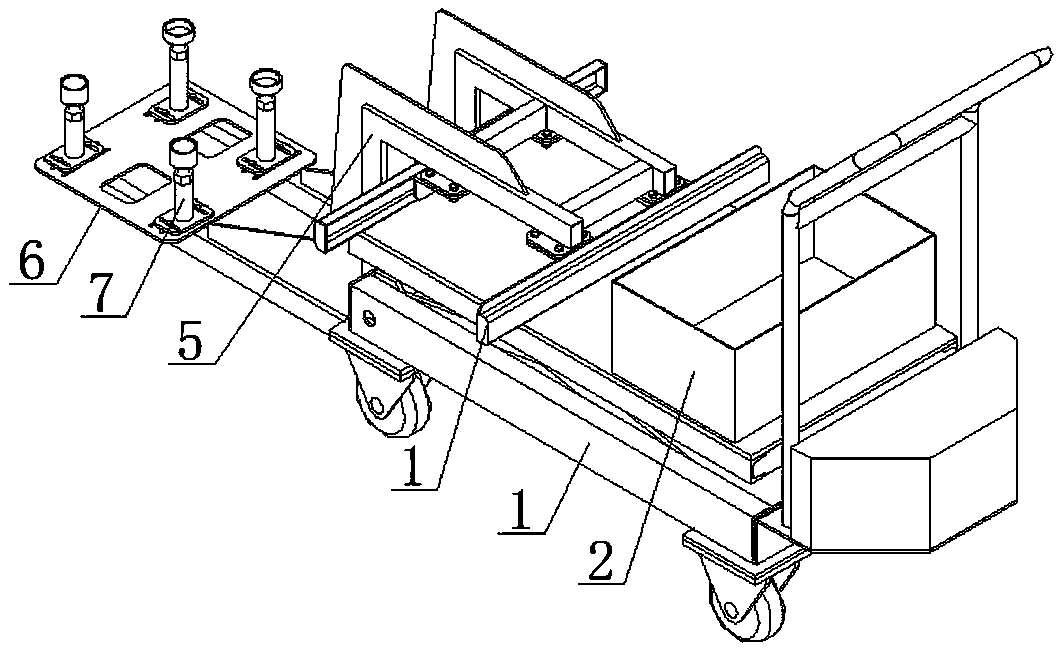

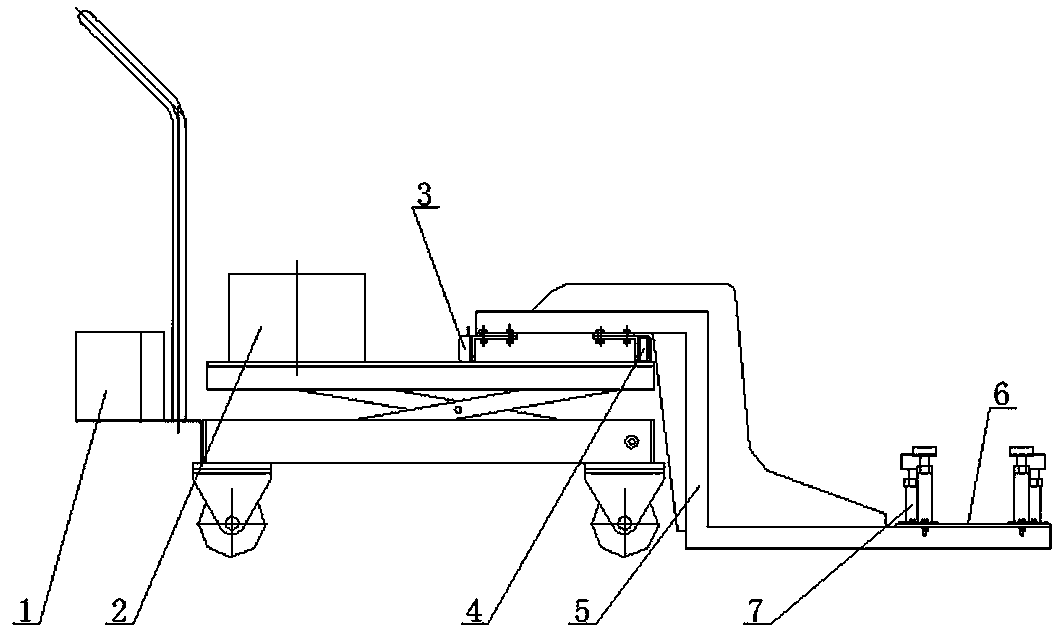

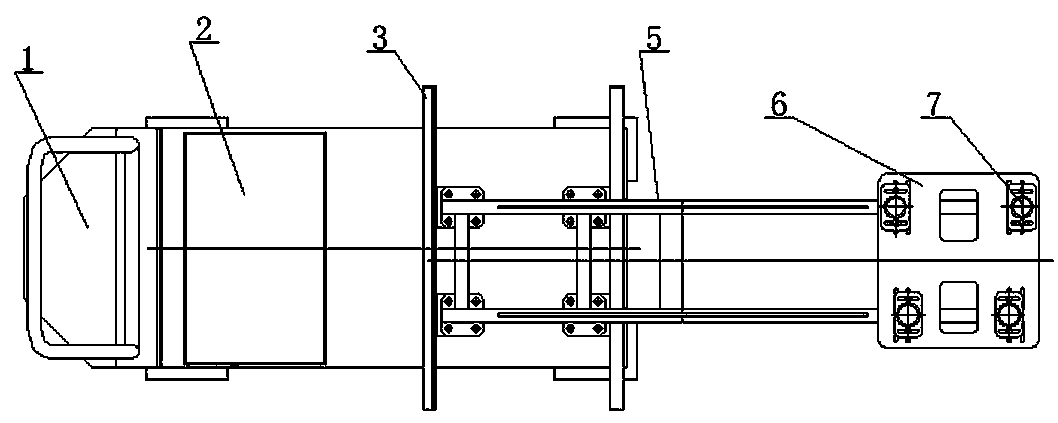

[0018] see figure 1 , figure 2 , image 3 , a locomotive unit brake removal, installation and transfer mechanism, including an electric lifting flat car 1, a sliding track 3, a roller bearing 4 cooperating with the sliding track 3, a Z-shaped support frame 5, a fixed base plate 6 and an adjustment seat 7; the electric lifting flat car The counterweight box 2 is installed on the lifting platform of 1, the sliding track 3 is fixedly installed on the lifting platform of the electric lifting flat car 1, the roller bearing 4 is connected and fixed with the upper end plate of the Z-shaped support frame 5 through a thread structure, and the Z-shaped support frame 5 The roller bearing 4 can slide on the sliding track 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com