Tie rod joint spraying rack

A technology of pull rods and hangers, applied in the direction of spraying devices, etc., can solve the problems of inconvenient disassembly and replacement, no separate hanger angle swing adjustment, no height adjustment and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

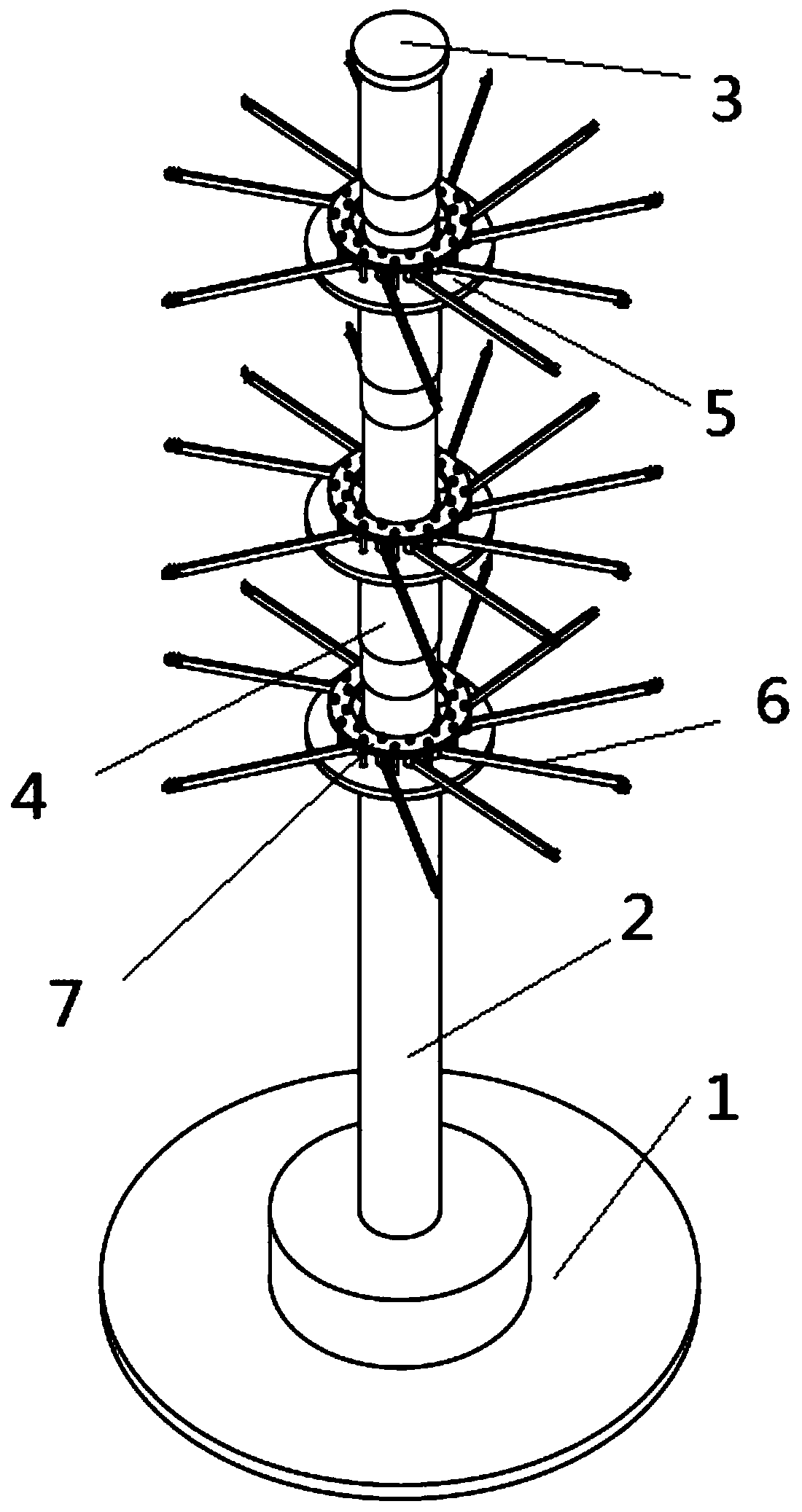

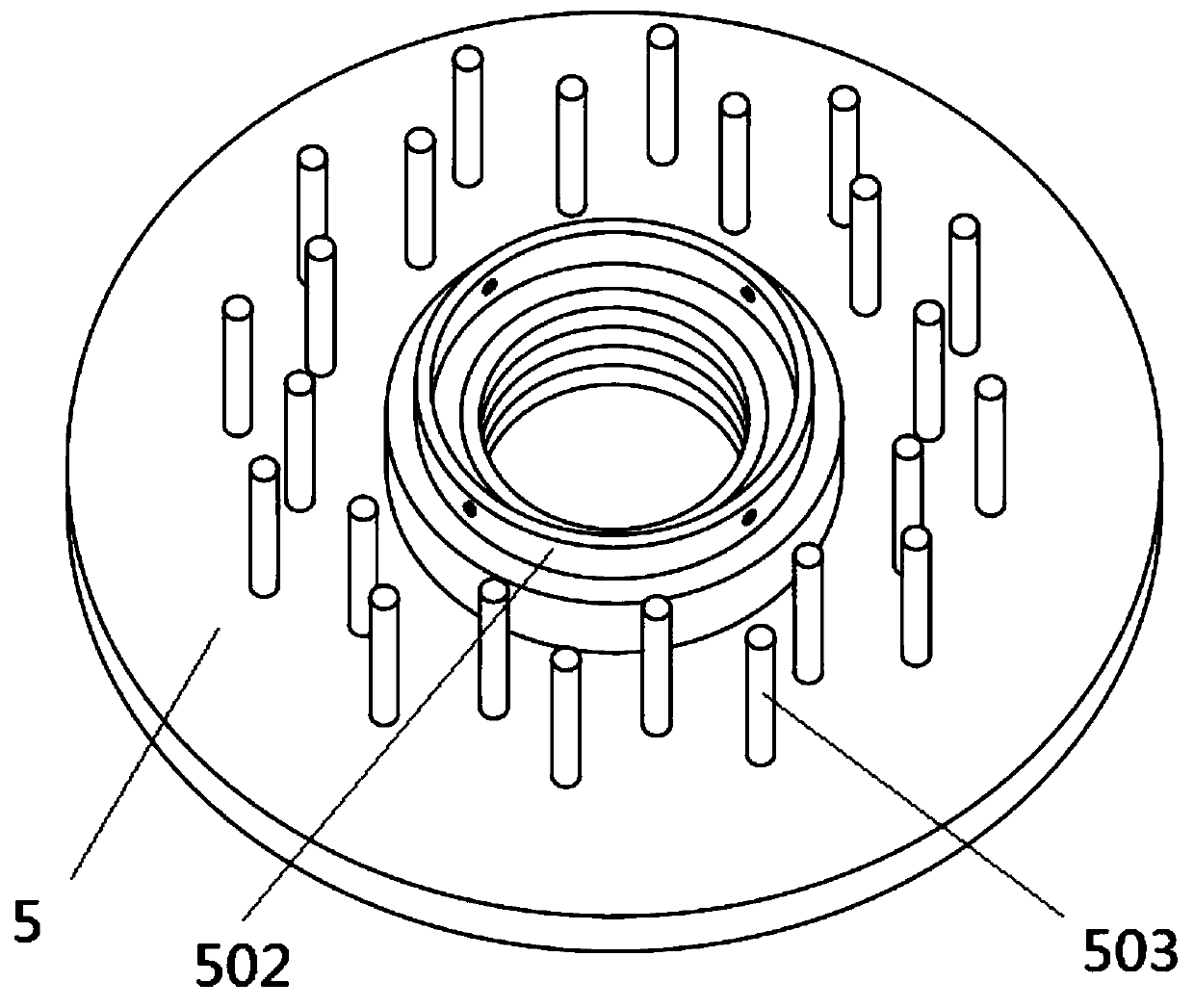

[0030] as attached figure 1 to attach Figure 4 Shown:

[0031] The present invention provides a rod joint spraying hanger, which includes a base 1, a sleeve 2, a top cover 3, a telescopic sleeve 4, a mounting plate 5, a bottom plate shoulder 501, a top plate shoulder 502, a mounting rod 503, a hanger rod 6, Mounting cylinder 601, movable hanger 602, pressing plate 7 and pressing threaded cylinder 701; the top of the base 1 is integrally provided with a round table structure, and the middle top of the round table is fixedly provided with a screw by welding; The end is fixedly provided with a sleeve 2 by welding, and four sets of through holes are opened on the top of the sleeve 2; the bottom of the mounting plate 5 is integrally provided with a bottom shoulder 501, and four sets of screw holes are opened around the bottom shoulder 501; The bottom disk shoulder 501 can be inserted into the screw hole of the bottom disk shoulder 501 through the through hole of the casing 2 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com