Inner hole special-shaped spring assembly device

An assembly device and special-shaped card technology, which is applied in the field of mechanical devices, can solve the problems that the opening position of the circlip cannot be guaranteed, the pressing force is difficult to control, and affects the assembly quality, etc., and achieves the effect of simple structure, compact layout, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

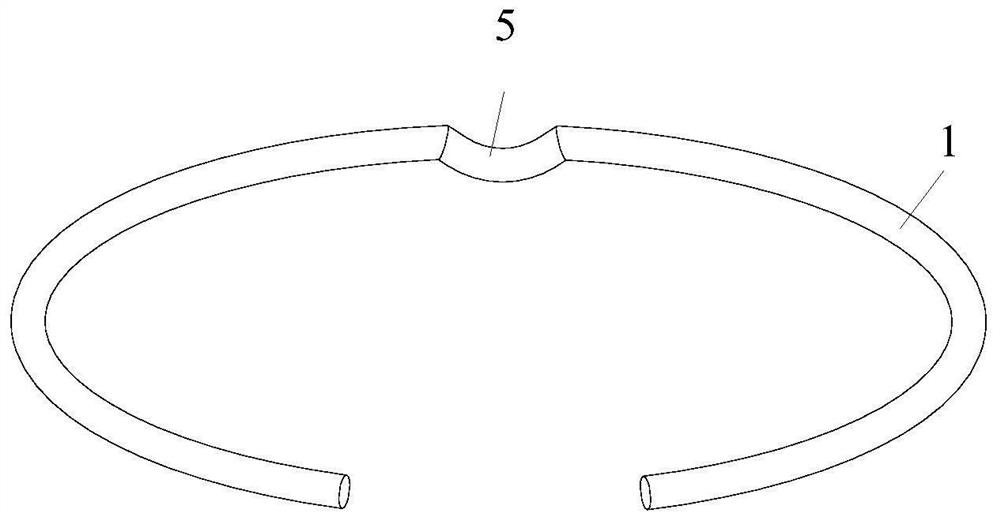

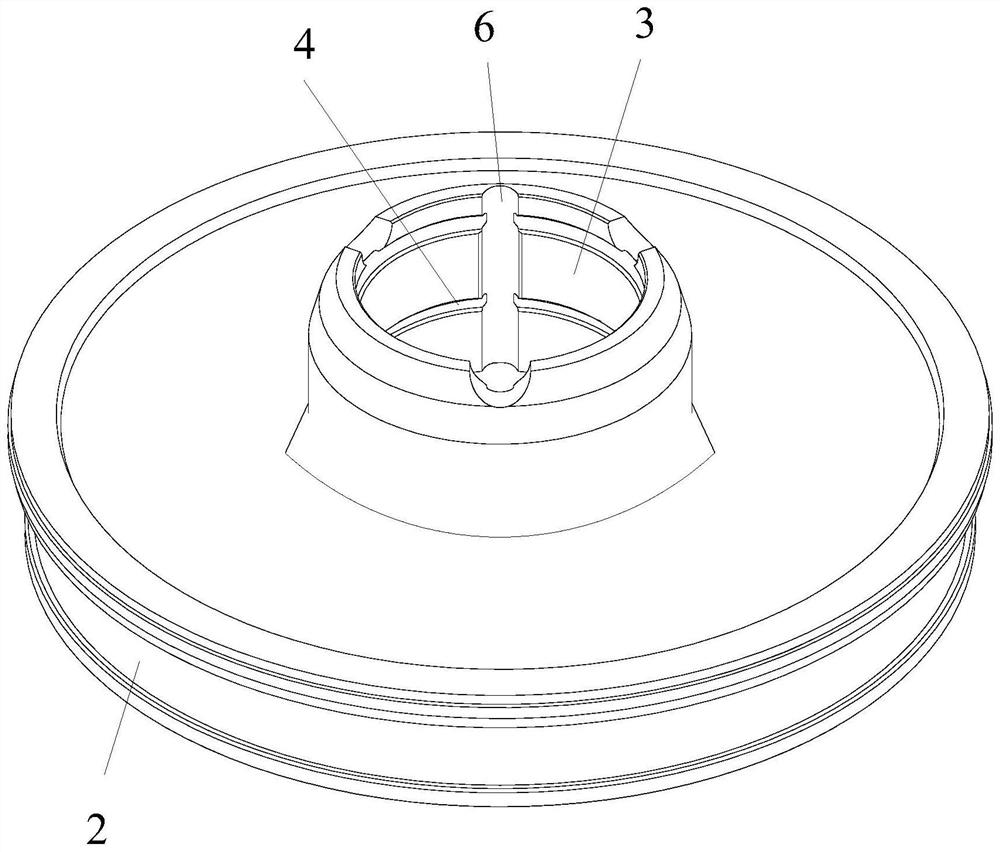

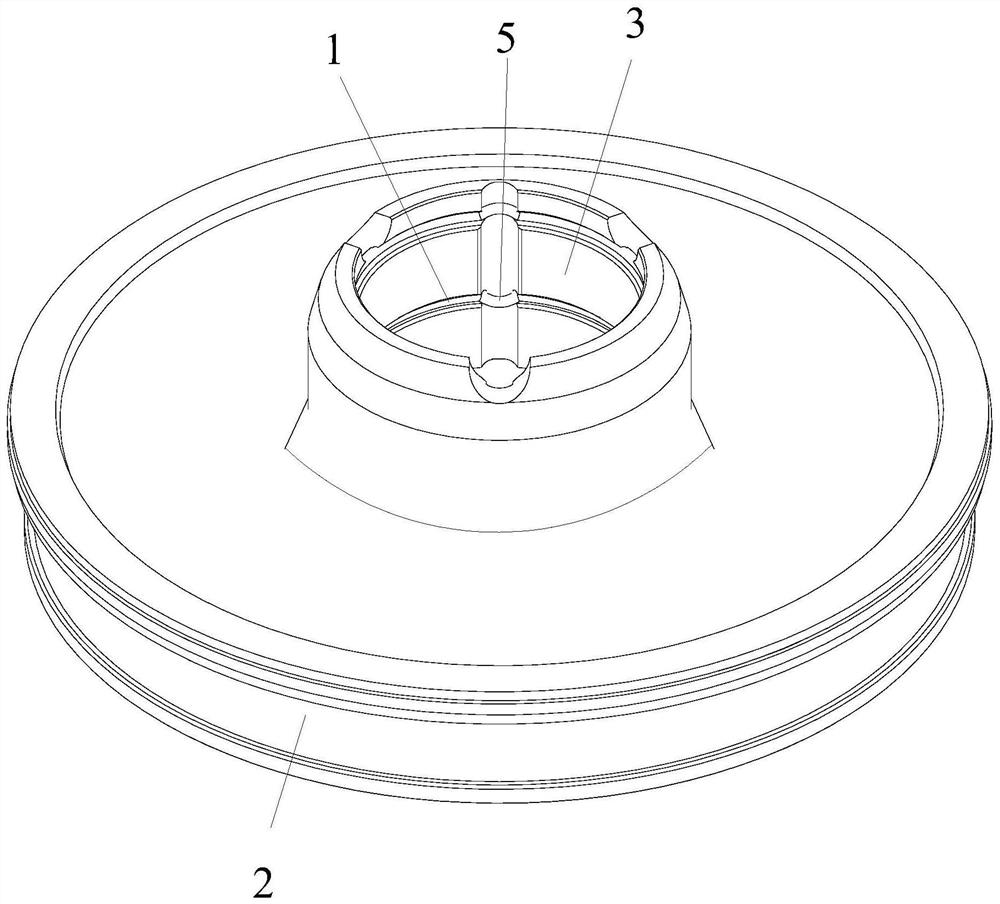

[0032] see Figure 1 to Figure 12 , this embodiment discloses an assembly device for special-shaped circlips with inner holes. There is a circle of horizontal circlip groove 4 for installing the circlip 1, the middle section of the circlip 1 is provided with a special-shaped section 5, and the special-shaped section 5 of the circlip 1 protrudes along the direction parallel to the axis of the circlip 1 Correspondingly, a vertical groove 6 is formed on the inner side wall of the central hole 3 of the pulley 2, and the groove 6 corresponds to the special-shaped section 5 of the circlip 1.

[0033] The device include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com