Feeding machine capable of preventing feed from sliding down automatically

A feeding machine and feed technology, applied in animal repellents, climate change adaptation, animal husbandry, etc., can solve the problems of fatigue fracture of vibrating sheets or elastomers, failure to achieve control effects, and high feed breakage rate, and achieve convenient The effect of mass production, low cost and small packaging volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

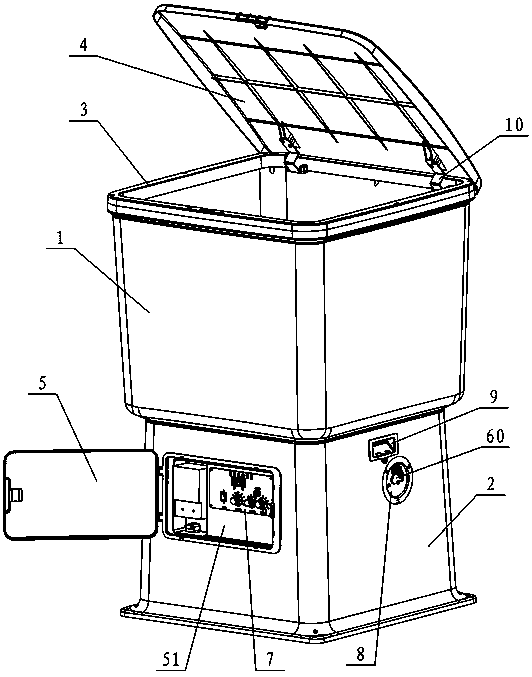

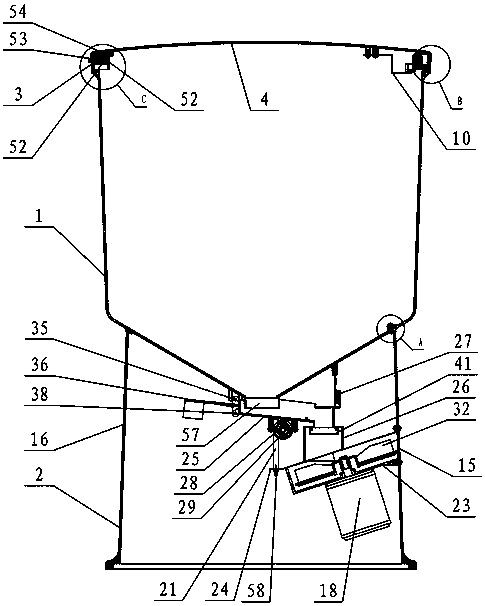

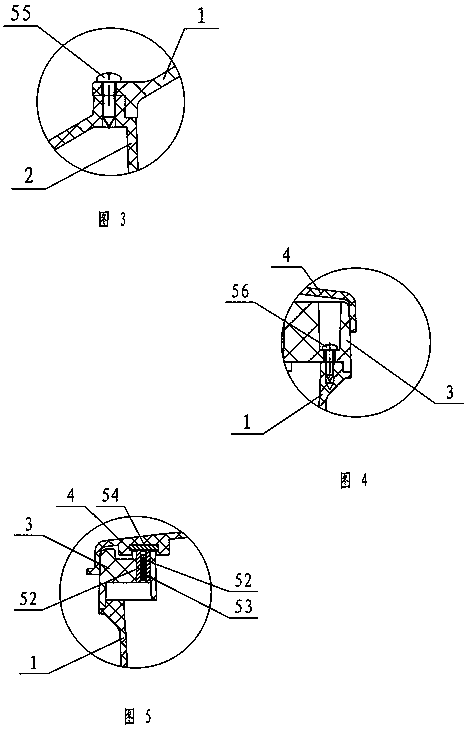

[0048] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-28 :

[0049]A feed feeding machine that prevents feed from sliding down automatically is mainly composed of a chassis, a controller 7, a feeding mechanism, and a throwing mechanism. The vibrating feeding chute 25 slides down through the feeding channel comprising the material receiver 26 and falls onto the throwing tray 32 of the throwing mechanism. Near the highest position of the elastic piece or weight 66, the elastic piece includes a metal spring or other elastic body. The counterweight 66 is arranged on the other side of the supporting shaft 64 at the non-feeding port end of the feeding chute 25 . When the feeding trough was not working, the feeding mouth end was stopped at the near highest position, and the 25 slopes of the feeding trough were reduced or the feed would not slide down automatically in the near horizontal state. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com