Supporting device for formwork system using Bailey frame and its application method

A technology of support device and belay frame, which is applied to the connection of formwork/template/work frame, formwork/formwork/work frame, and on-site preparation of building components, etc., can solve the problem of inconvenient height adjustment of the support device, Inconvenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

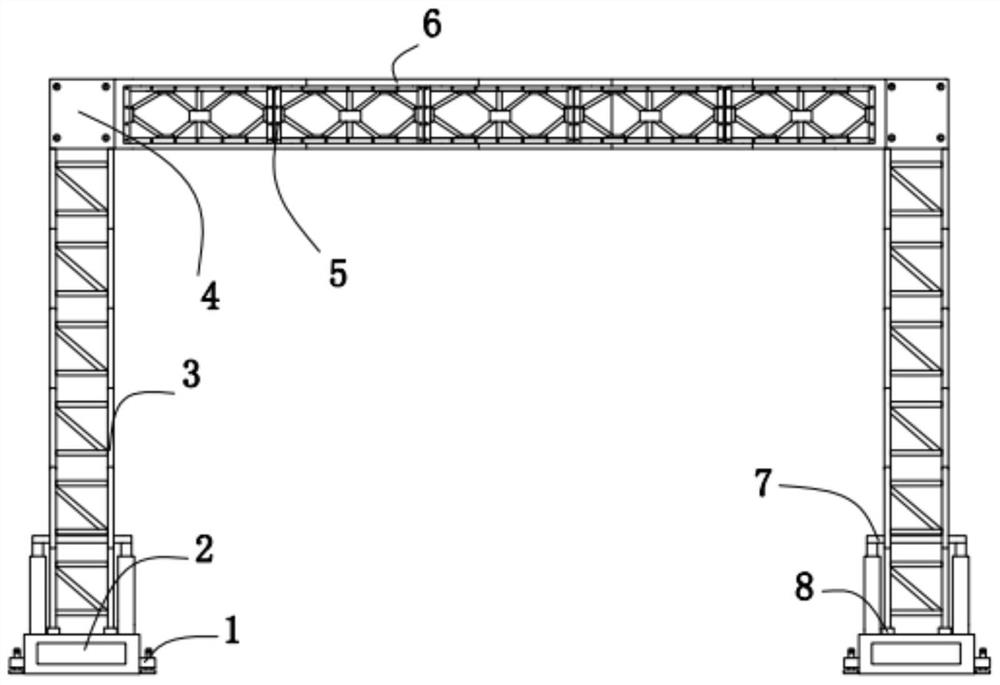

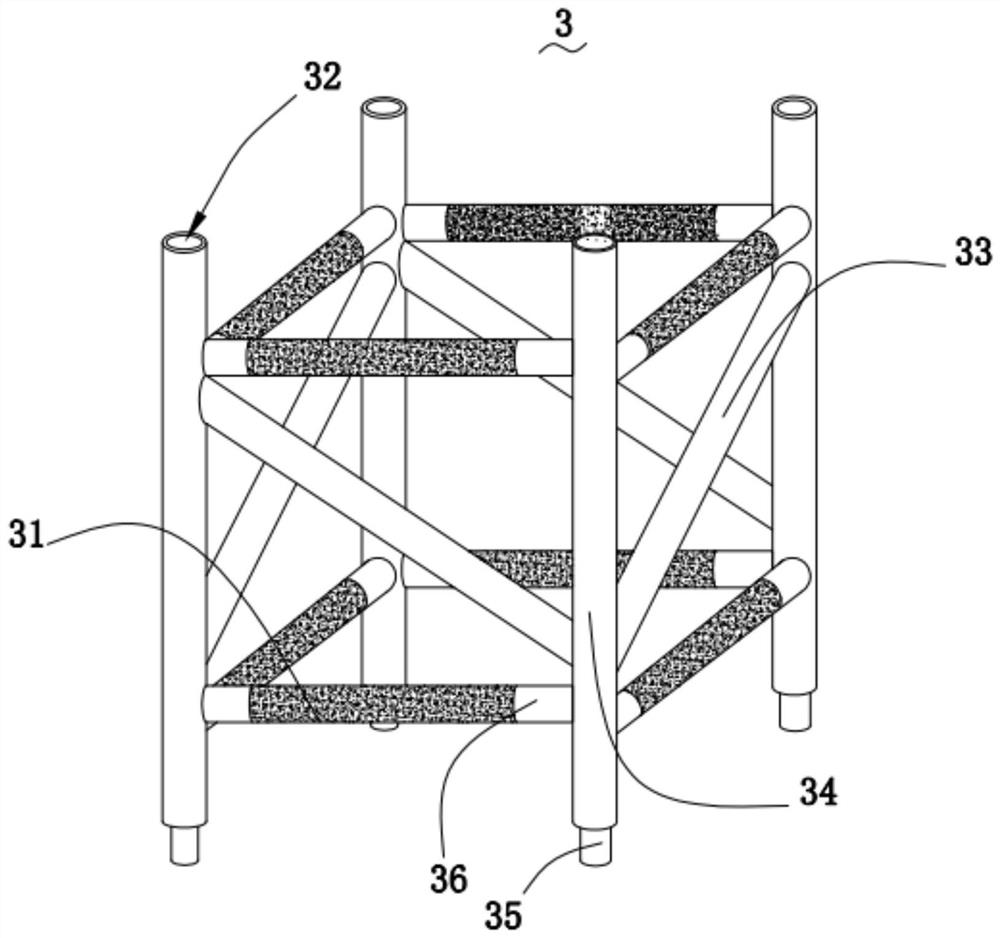

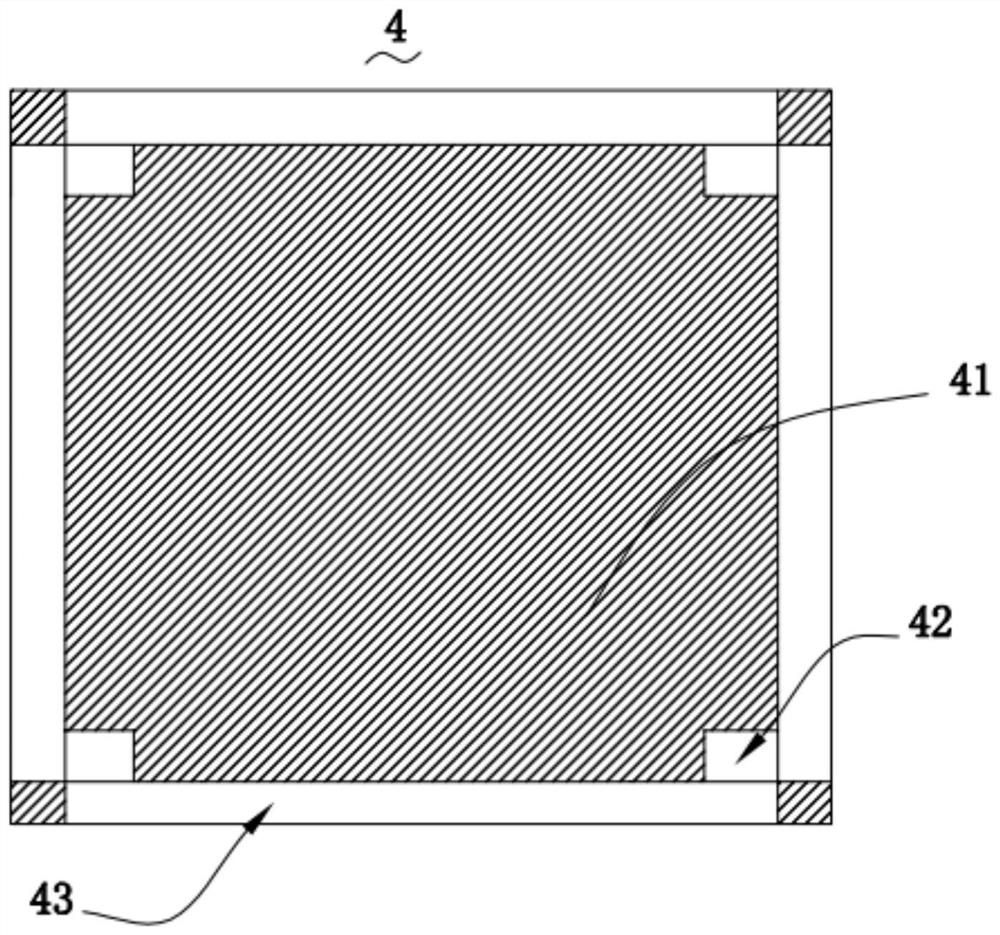

[0031] Please refer to figure 1 , figure 2 , image 3 and Figure 4 ,in, figure 1 A structural schematic diagram of a preferred embodiment of the supporting device and the method of use thereof for the formwork system that adopts the Bailey frame provided by the present invention; figure 2 for figure 1 Schematic diagram of the structure of the support frame shown; image 3 for figure 1 The schematic diagram of the structure of the connector shown; Figure 4It is a schematic diagram of the connection structure of the fixing structure and the driving structure of Embodiment 1 of the supporting device of the formwork support system using a Bailey frame and its use method provided by the present invention. The supporting device of the formwork system that adopts the Bailey frame includes: four connecting heads 4; a plurality of connecting rods 6, and a plurality of connecting rods 6 are arranged between two of the four connecting heads 4; Frame 5, a plurality of Bailey f...

Embodiment 2

[0039] Please refer to figure 1 , figure 2 , image 3 and Figure 5 ,in, figure 1 A structural schematic diagram of a preferred embodiment of the supporting device and the method of use thereof for the formwork system that adopts the Bailey frame provided by the present invention; figure 2 for figure 1 Schematic diagram of the structure of the support frame shown; image 3 for figure 1 The schematic diagram of the structure of the connector shown; Figure 5 It is a schematic diagram of the connection structure of the fixing structure and the driving structure of the second embodiment of the supporting device of the formwork support system using a Bailey frame and its using method provided by the present invention. The supporting device of the formwork system that adopts the Bailey frame includes: four connecting heads 4; a plurality of connecting rods 6, and a plurality of connecting rods 6 are arranged between two of the four connecting heads 4; Frame 5, a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com