Engine rapid stalling control system

A control system and engine technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve problems such as seat vibration and poor comfort, and achieve the effect of speeding up the flameout rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

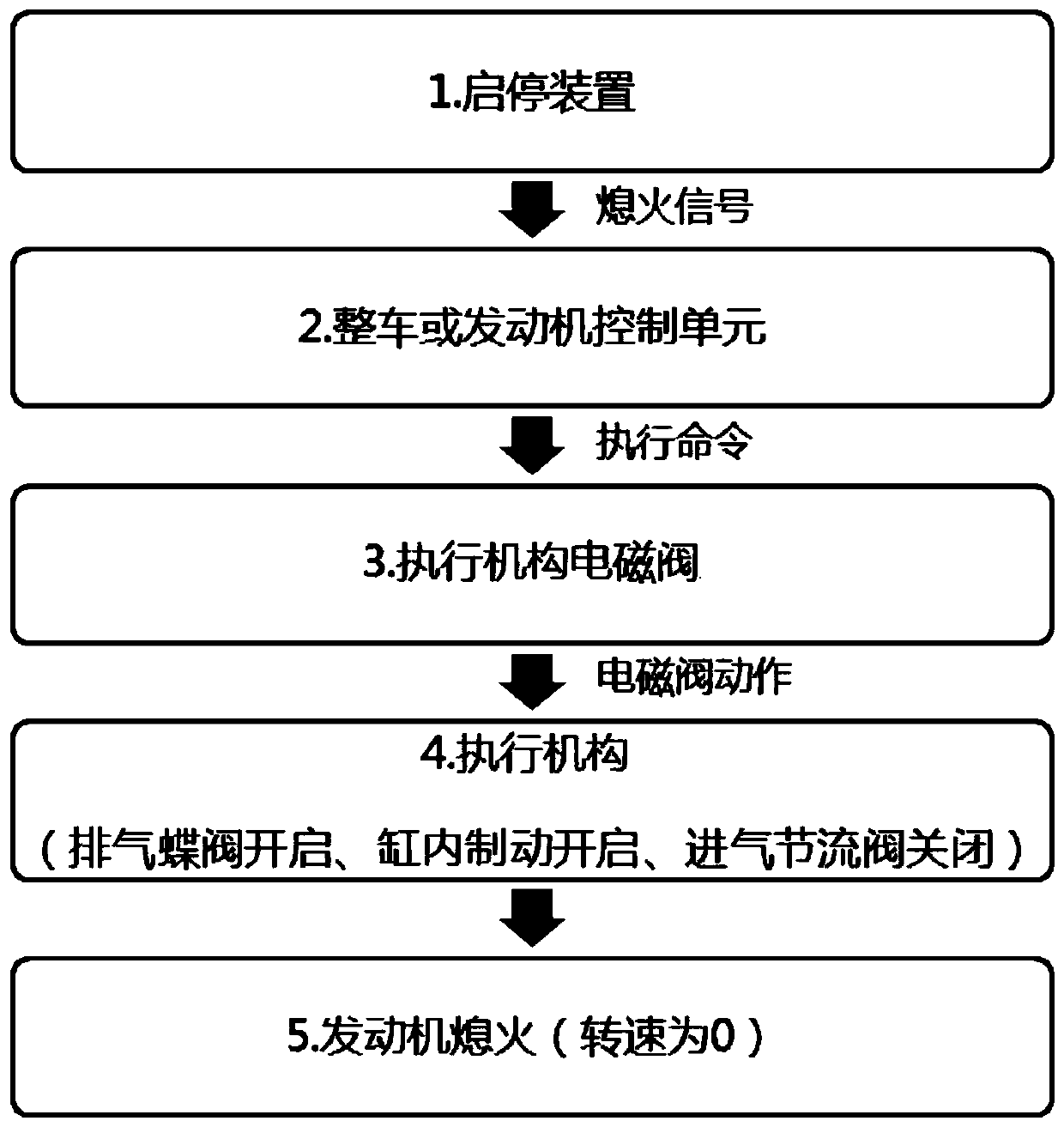

[0018] Such as figure 1 As shown, the present invention provides a control system for rapid engine flameout, which is used in the process of engine flameout, including a start-stop device 1 , a vehicle or engine control unit 2 , an actuator solenoid valve 3 and an actuator 4 .

[0019] The flameout signal is sent by the start-stop device 1 according to the operation needs of the user, and the signal transmission is carried out according to the J1939 protocol. The flameout signal is transmitted to the vehicle or engine control unit 2 through the wiring harness, but the vehicle or engine control unit 2 will not enter the power-off state immediately, and the execution command will be sent to the actuator solenoid valve 3 through the wiring harness through the interactive processing of the signal. or other electronic control components, after receiving the order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com