Electronic control system and variable fuel injection pressure control method for internal combustion engine

一种电子控制系统、喷油压力的技术,应用在电气控制、发动机控制、燃料喷射控制等方向,能够解决无法实现喷油压力实时变化调整等问题,达到避免湿壁效应、减少PN排放的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

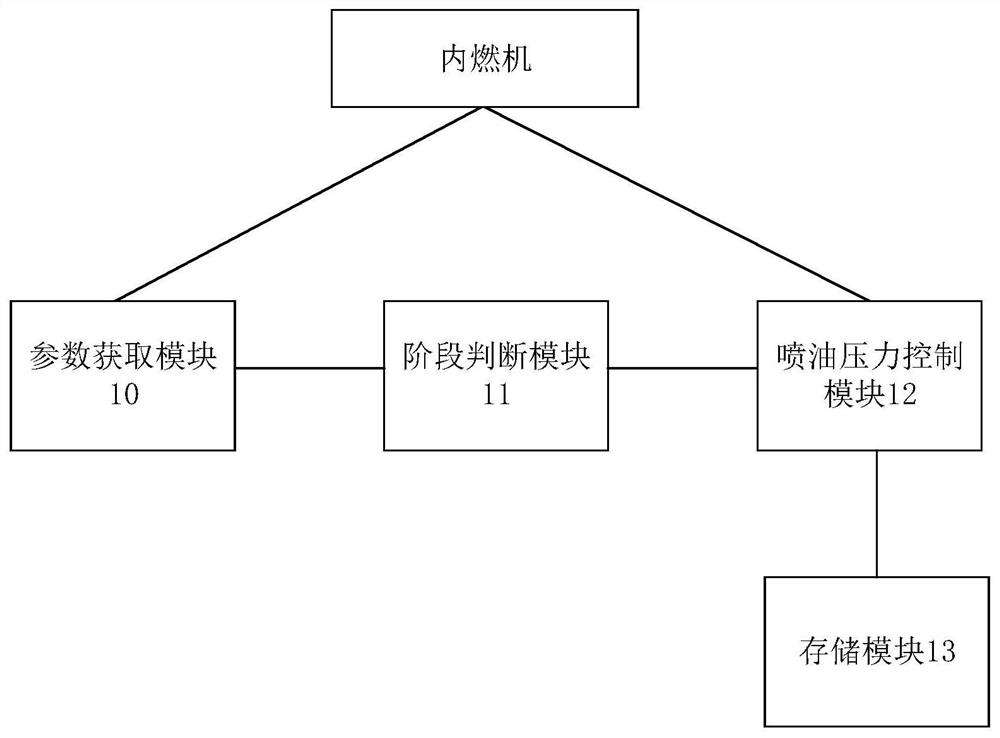

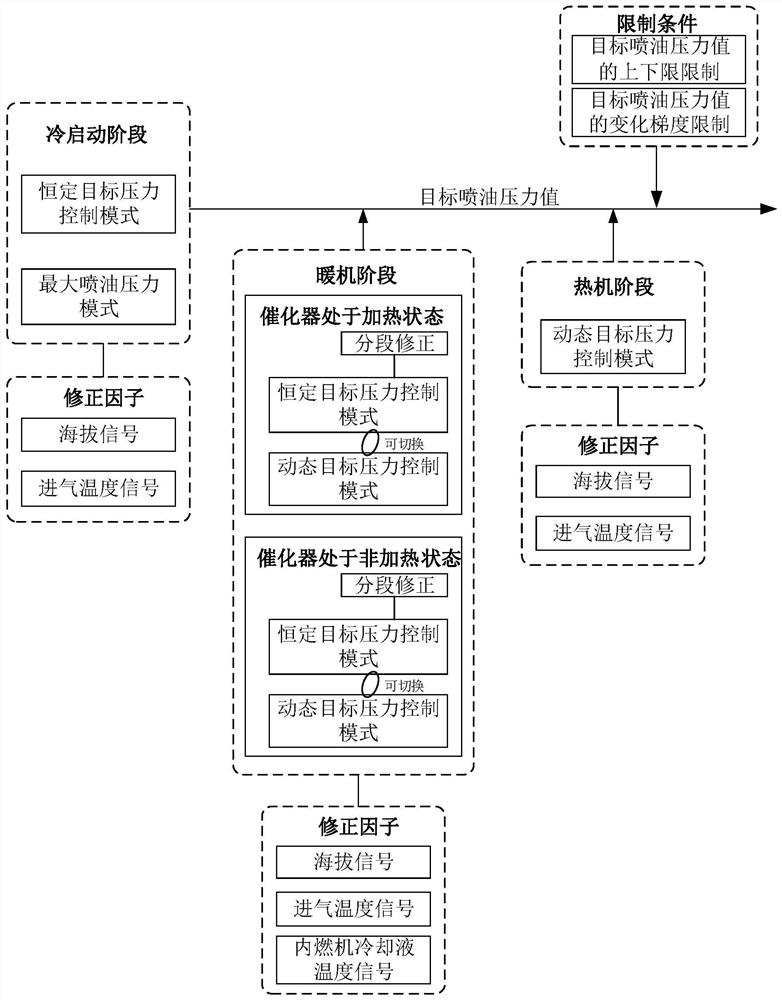

[0060] Please refer to figure 1 , which is a schematic structural diagram of the electronic control system in this embodiment. like figure 1 As shown, the electronic control system includes: a storage module 13, a parameter acquisition module 10, a phase judgment module 11 and a fuel injection pressure control module 12, and the storage module 13 is used to store the target fuel injection pressure list of each working stage of the internal combustion engine, The target fuel injection pressure list is a table about the corresponding relationship between working stage influencing parameters and target fuel injection pressure values, and the working stage includes a cold start stage, a warm-up stage and a warm-up stage; the parameter acquisition module 10 is used to obtain The working stage judgment parameter and the current working stage influencing parameter of the current internal combustion engine; the stage judgment module 11 is used to judge the current working stage of th...

Embodiment 2

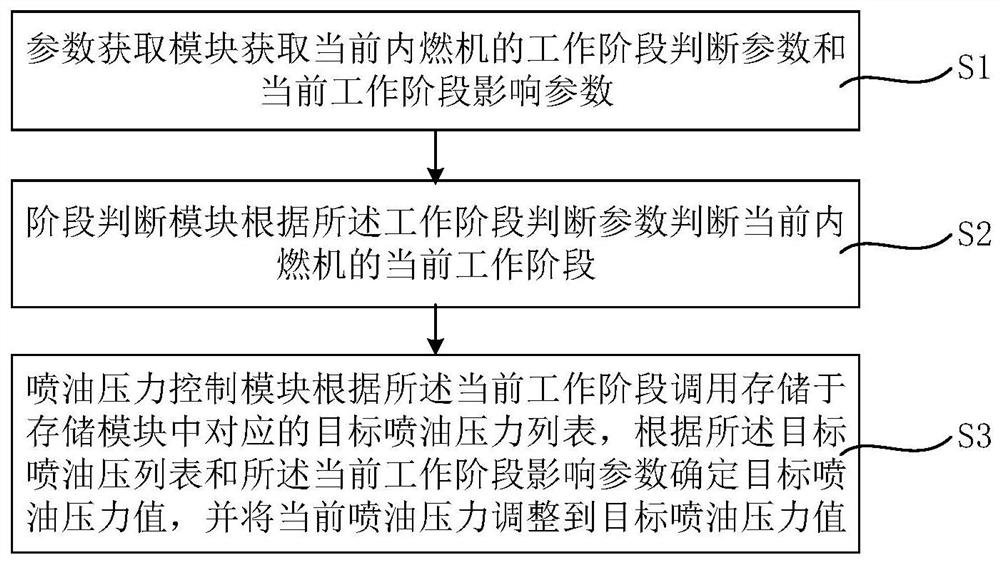

[0068] Please refer to figure 2 , which is a flow chart of the method for controlling the variable fuel injection pressure of the internal combustion engine in this embodiment. like figure 2 As shown, the variable fuel injection pressure control method of the internal combustion engine uses the electronic control system as described above. The internal combustion engine burns the fuel inside the machine and converts the heat energy released by it directly into a thermal internal combustion engine for power. The internal combustion engine The variable fuel injection pressure control method mainly includes the following steps:

[0069] Firstly, step S1 is executed: the parameter acquisition module acquires the working stage judgment parameters of the current internal combustion engine and the influencing parameters of the current working stage;

[0070] Next, step S2 is executed: the stage judging module judges the current working stage of the current internal combustion eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com