spliced steel purlin

A spliced, steel purlin technology, used in construction, excavation, infrastructure engineering, etc., can solve the problems of large demolition loss, low construction work efficiency, large workload, etc., achieve fast construction work efficiency, improve construction work efficiency, and eliminate welding. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The use case of the present invention is described below in conjunction with accompanying drawing: this case is carried out under the premise of the present invention, has provided detailed embodiment and concrete operation process, but protection scope of the present invention is not limited to following case.

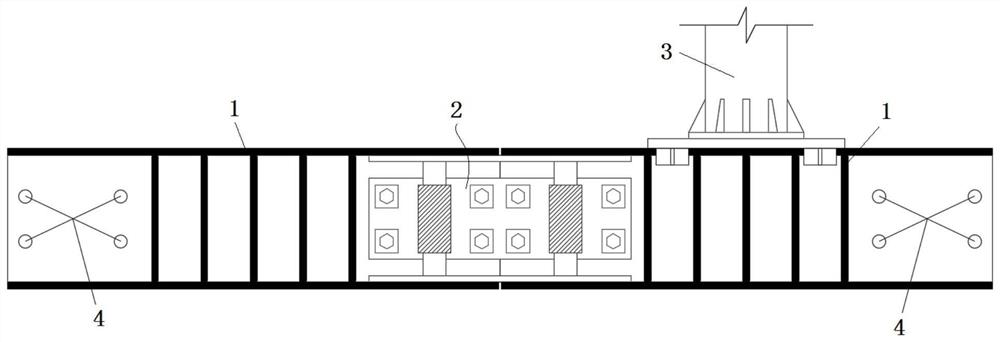

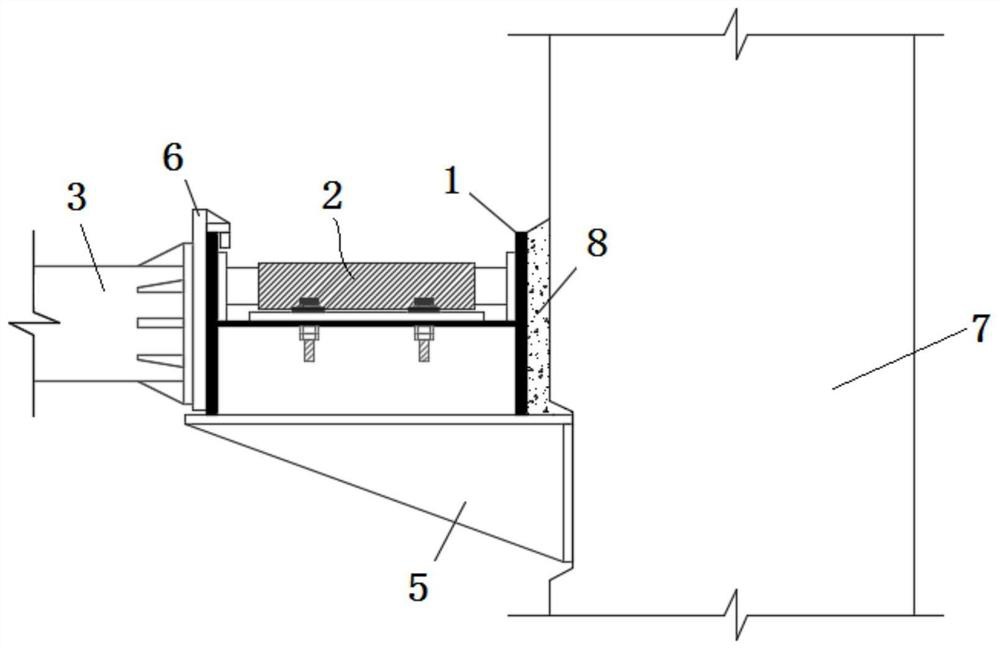

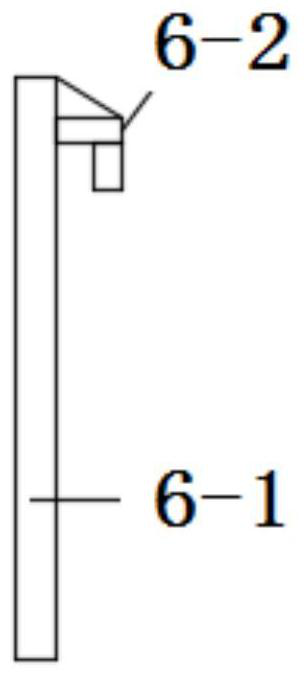

[0018] Such as figure 1 , As shown in 2, a spliced steel purlin includes a steel purlin 1, a purlin support 5, a purlin connecting member 2 and a supporting end hanging plate 6. The section steel purlin 1 is installed on the enclosure structure 7 through the purlin support 5, the section steel purlin 1 has a reserved position for installing the purlin connecting member 2, and several sections are connected by bolts and purlin connecting member 2. The profiled steel purlins 1 are spliced together to form a whole.

[0019] Sectional steel purlin 1 is mainly composed of section steel, reinforcing ribs and reserved installation positions for connecting compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com