Tea feeding and conveying device

A technology of tea and material feeding, which is applied in the field of tea feeding and feeding equipment, can solve the problems of affecting the quality of finished products, heavy workload, and low degree of automation, so as to improve uniformity and stability, reduce labor costs, and have a high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with accompanying drawing:

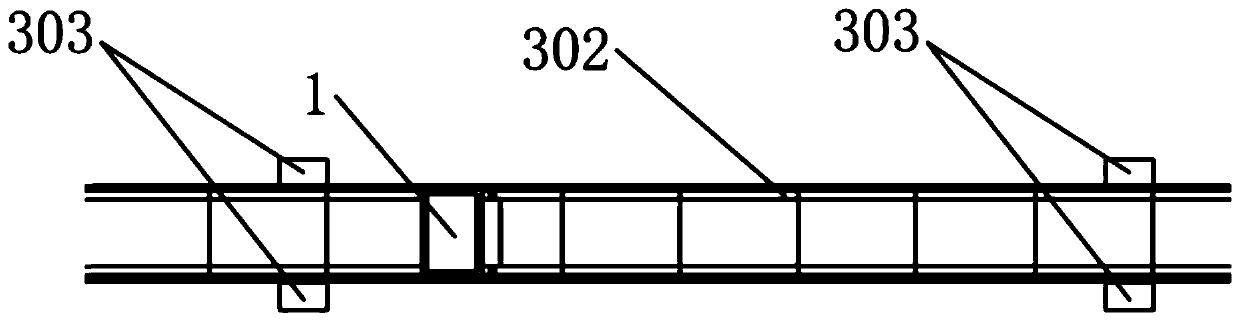

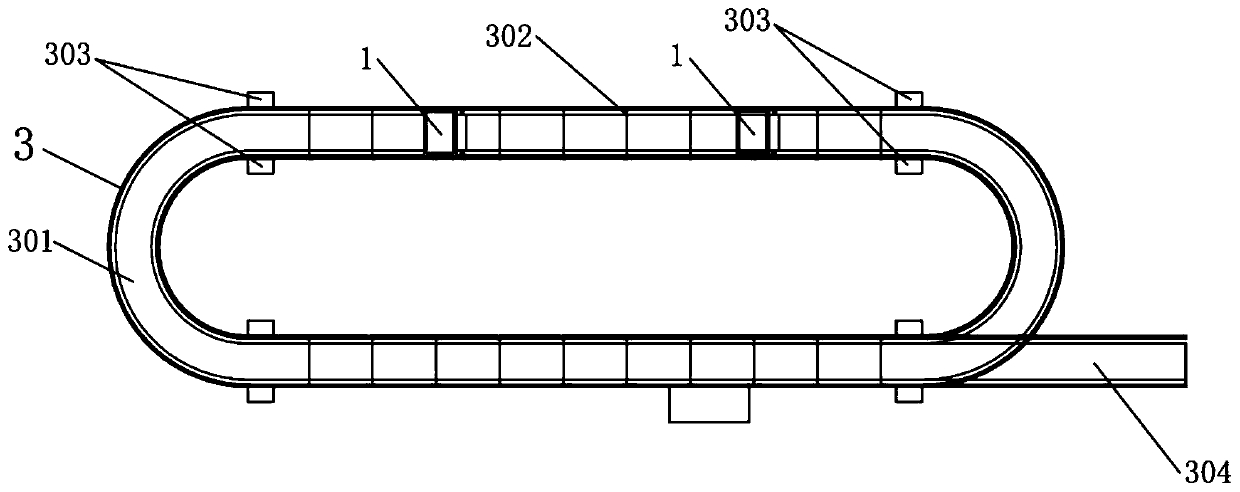

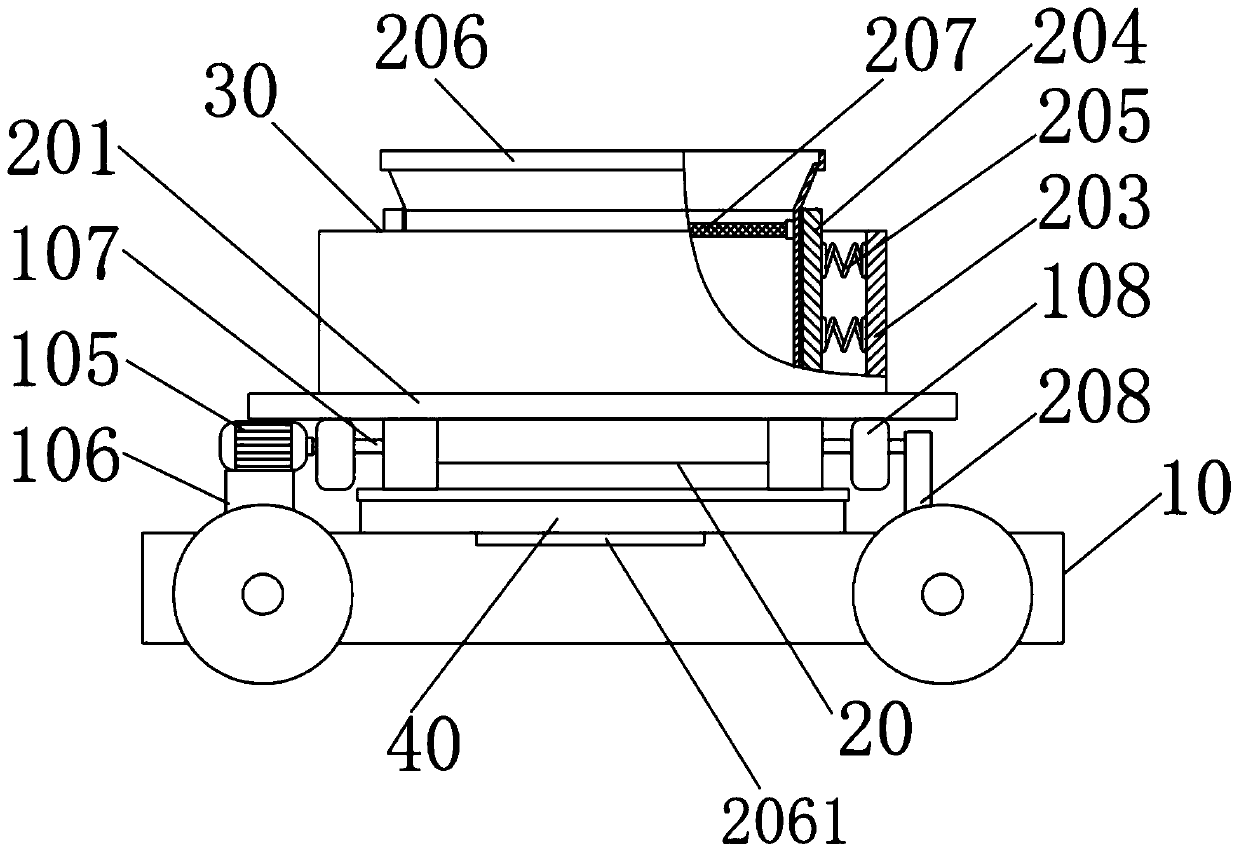

[0048] Such as Figure 1-8 As shown, the present invention provides a specific embodiment of tea feeding and feeding equipment, including at least one feeding trolley 1, each feeding trolley 1 is equipped with a PLC; used to guide the above-mentioned feeding trolley 1 to multiple kneading machines Straight track 302 or circular track 3 for transporting tea leaves; and a feeding device for loading quantitatively metered tea leaves into the above-mentioned feeding trolley 1; therefore, the feeding belt 2 of the feeding device adopts speed detection, high-precision weighing sensor Detection and integral algorithm are combined to achieve the guarantee of measurement accuracy, and fuzzy control can also be performed according to historical data; the above-mentioned feeding trolley 1 is set to run on the straight track 302 or the circular track 3, and runs along the straight trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com