Plunger for syringe, manufacturing method thereof, and medical syringe

A manufacturing method and a technology for a syringe, applied in the directions of hypodermic injection instruments, etc., can solve the problems of detachment of the main body of the piston, siphon phenomenon, and flow of medicinal liquid to the patient, etc., to prevent detachment, improve the degree of welding and become uneven, and the degree of welding uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0046] [Medical Syringes]

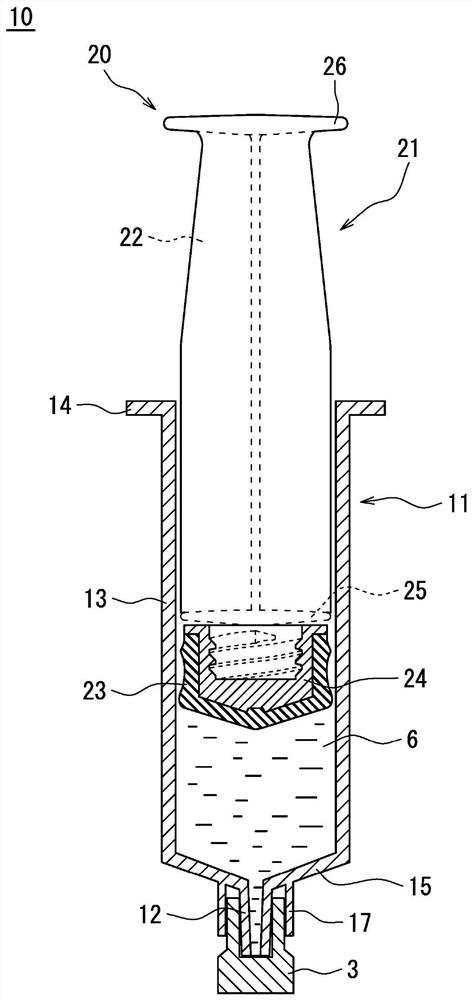

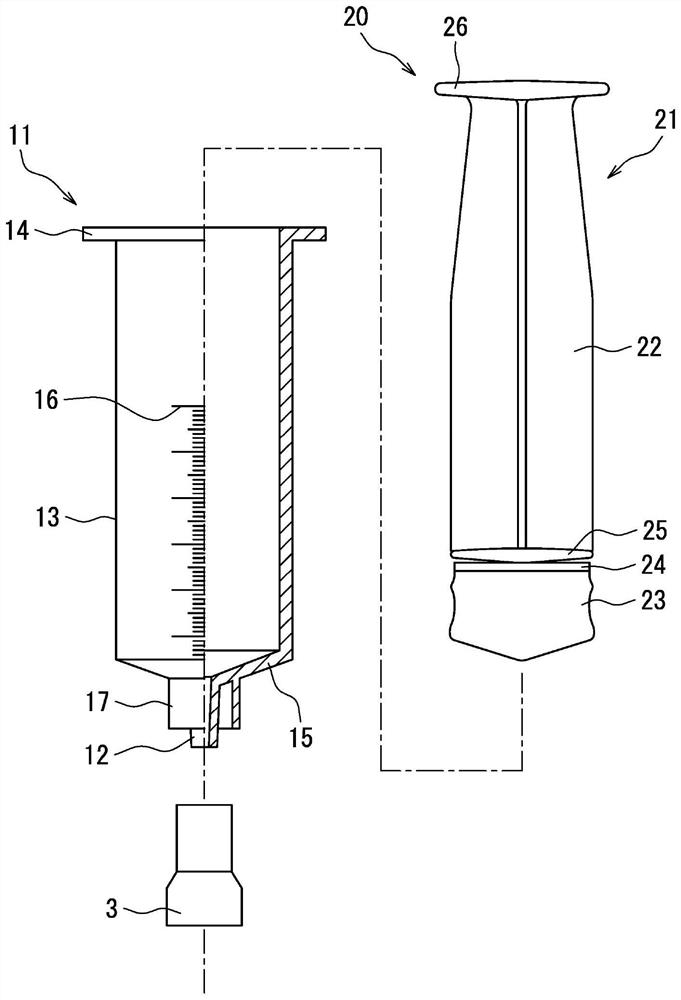

[0047] As the medical syringe (hereinafter referred to as "syringe") of this embodiment, a prefilled syringe will be described below as an example. figure 1 is a cross-sectional view of the syringe. figure 2 It is a side view showing the syringe plunger (hereinafter referred to as "plunger") and the syringe outer cylinder (hereinafter referred to as "outer cylinder") of the syringe.

[0048] like figure 1 and figure 2 As shown, the syringe 10 of this embodiment includes: an outer cylinder 11 having a nozzle portion 12 at the front end; a cap 3 for sealing the nozzle portion 12; a plunger 21 having a gasket 23 at a connecting portion; The medicinal solution 6 in the chamber formed by the cap 3 and the gasket 23.

[0049] The outer cylinder 11 includes: a cylindrical portion 13 substantially formed in a cylindrical shape; a nozzle portion 12 provided at the front end of the cylindrical portion 13; and a finger grip 14 provided at the rear end of...

Embodiment approach 2

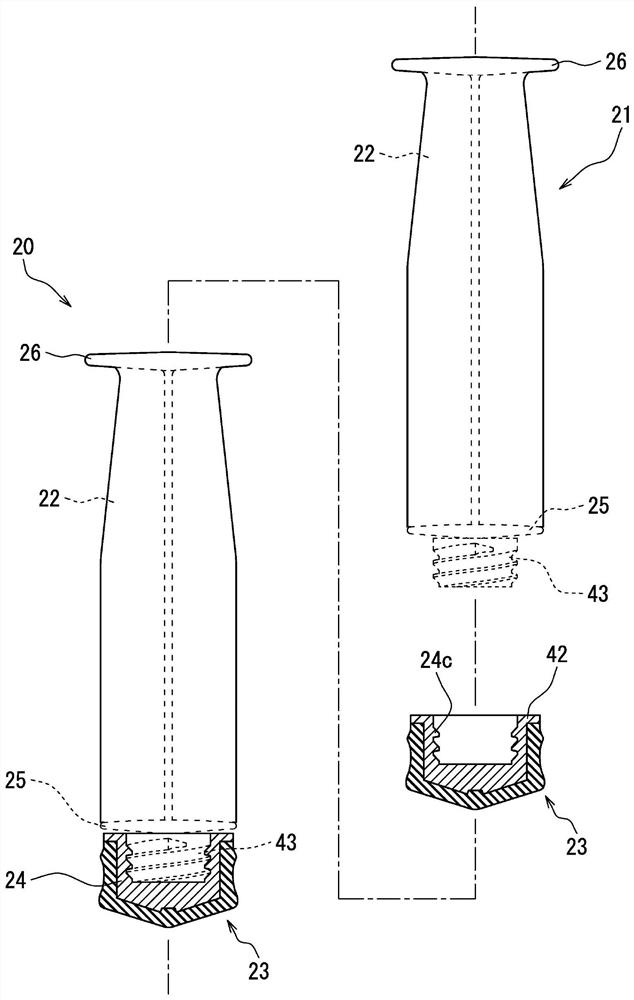

[0094] based on Figure 9 and Figure 10 , Embodiment 2 of the present invention will be described below. In addition, members having the same functions as those in Embodiment 1 are assigned the same reference numerals, and their descriptions are omitted. Figure 9 It is a sectional view showing the syringe plunger of the medical prefilled syringe according to the second embodiment. (a) of Fig. 10 is a side view showing the gasket and connecting portion of the syringe plunger, (b) of this figure is a sectional view showing the gasket and connecting portion, and (c) of this figure is a side view showing the gasket and connecting portion. Sectional view of the connection.

[0095] Regarding this Embodiment 2, if Figure 9 and Figure 10 As shown, the point that the gasket 23 is integrally provided by welding with the connection portion 61 is the same as that of the first embodiment. In addition, the plunger 21 and the connecting portion 61 have a connectable and detachable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com