A test and calibration bench for shafting strain measurement system

A technology of strain measurement and calibration platform, which is applied in the field of strain testing, can solve the problems of lack of methods and means of system calibration, and achieve the effects of simple structure, accurate determination of support point positions, and reduced requirements for axis alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

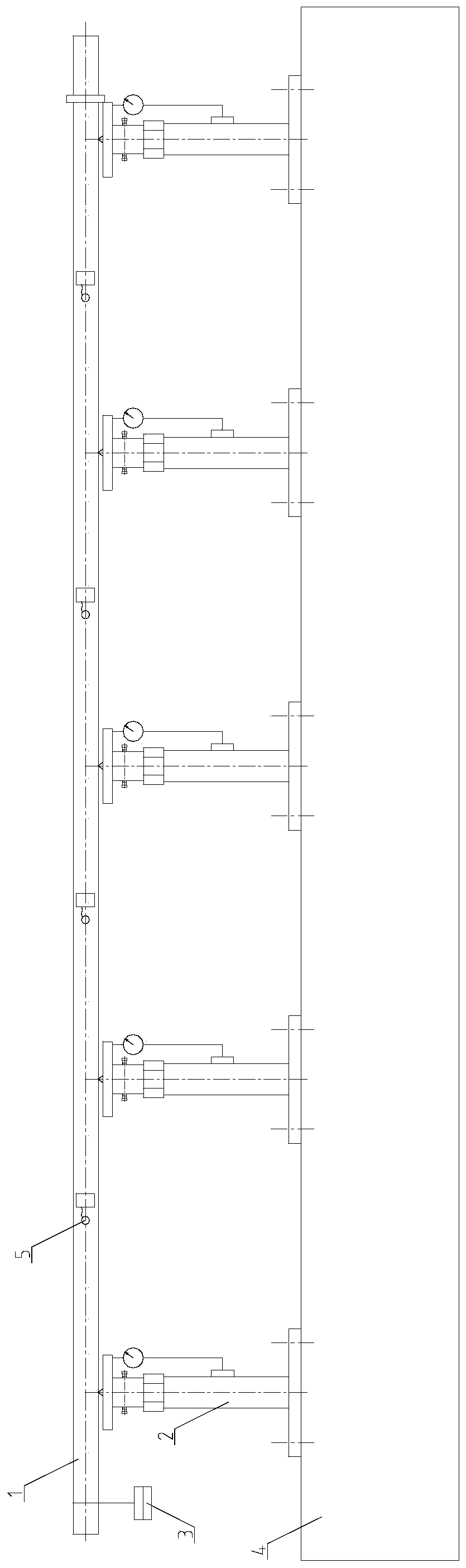

[0021] as attached image 3 As shown, the present invention provides a test and calibration bench for a shafting strain measurement system. The calibration bench includes a rotating shaft 1 , an elevation adjustment device 2 , a weight 3 , a platform 4 and a strain measurement system 5 .

[0022] Rotating shaft 1 is a solid shaft with equal diameter. The diameter range of the shaft can be φ40mm~φ100mm, and the diameter tolerance is required to be (0~0.02)mm. The outer surface of the shaft is marked with scale marks to determine the axial position. The zero point can be defined as Any end face. One end of the rotating shaft 1 is provided with a chuck to ensure that the axial position of the rotating shaft will not be affected during manual cranking.

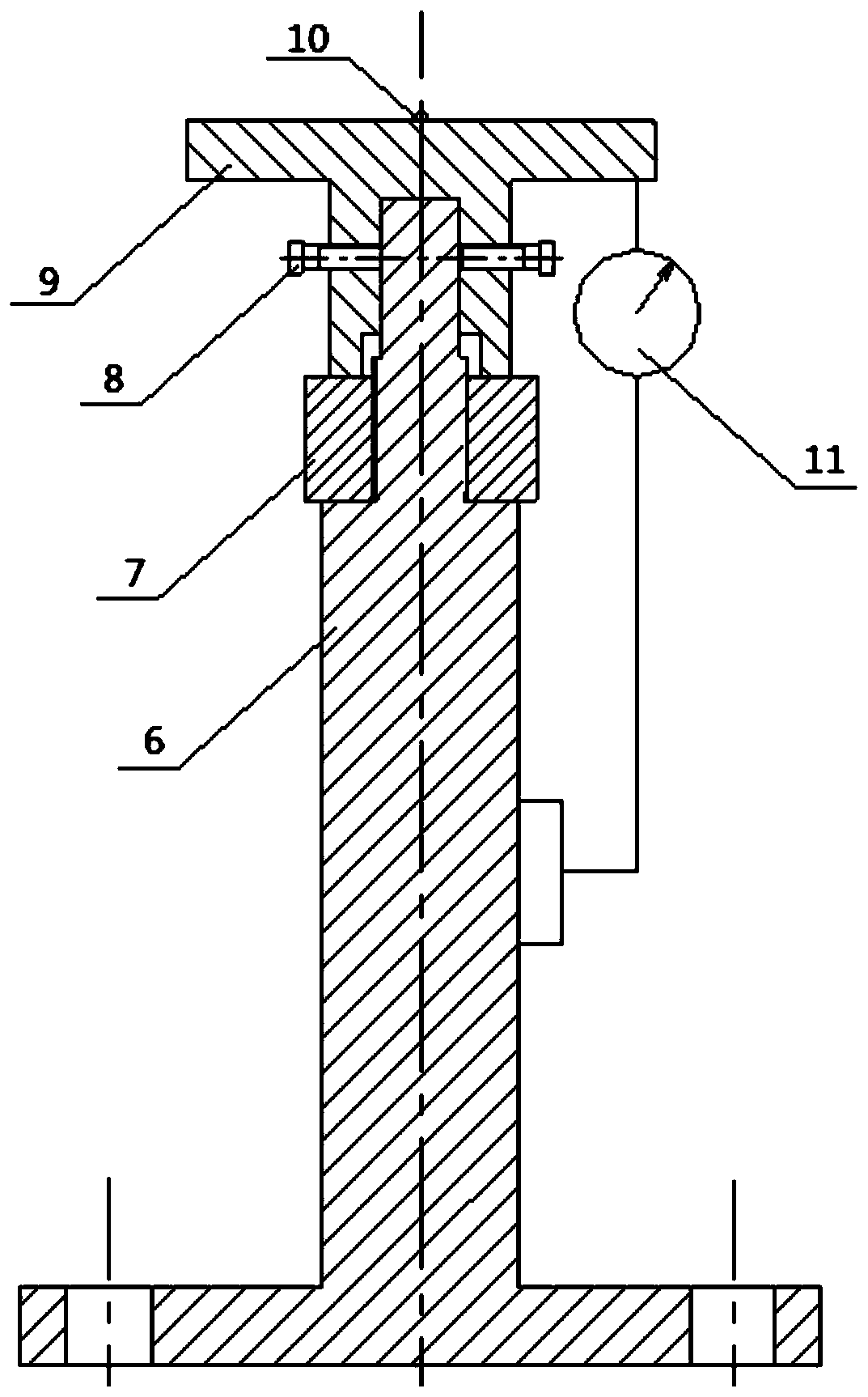

[0023] Such as figure 1 As shown, the elevation adjustment device 2 is composed of a support 6, an adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com