High-performance long-service-life EPDM pump valve body material

A long-life, high-performance technology, applied in the field of pump and valve materials, to achieve the effect of improving mechanical quality, improving market competitiveness and production efficiency, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A high-performance and long-life EPDM pump valve body material is made of the following substances by weight:

[0030] 45 parts of ethylene propylene rubber, 26 parts of nano-silica, 3 parts of calcium carbonate, 2 parts of epoxy soybean oil, 18 parts of plasticizer, 2 parts of activator, 0.5 parts of vulcanizing agent, 1 part of accelerator, 5 parts of modification filler.

[0031] Further, the particle size of the nano white carbon black is 30-70nm.

[0032] Further, the particle size of the calcium carbonate is 500-600 mesh.

[0033] Further, the preparation method of the modified filler comprises the following steps:

[0034] 1) First put the silicon substrate into the acetone solution for 6 minutes of ultrasonic treatment, then take out the silicon substrate and dry it for later use;

[0035] 2) Put the silicon substrate treated in step 1) into a magnetron sputtering apparatus, and then coat a layer of gold film with a thickness of 15-20nm on the surface of the ...

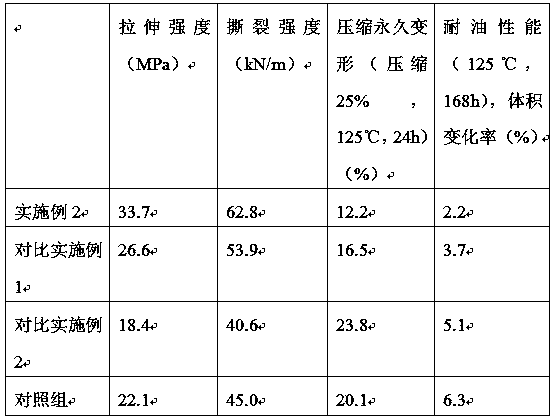

Embodiment 2

[0047]A high-performance and long-life EPDM pump valve body material is made of the following substances by weight:

[0048] 48 parts of ethylene propylene rubber, 28 parts of nano-silica, 5 parts of calcium carbonate, 3 parts of epoxy soybean oil, 20 parts of plasticizer, 2.3 parts of activator, 1 part of vulcanizing agent, 1.5 parts of accelerator, 7 parts of modification filler.

[0049] Further, the particle size of the nano white carbon black is 30-70nm.

[0050] Further, the particle size of the calcium carbonate is 500-600 mesh.

[0051] Further, the preparation method of the modified filler comprises the following steps:

[0052] 1) Put the silicon substrate into the acetone solution to soak and ultrasonicate for 7 minutes, then take out the silicon substrate and dry it for later use;

[0053] 2) Put the silicon substrate treated in step 1) into a magnetron sputtering apparatus, and then coat a layer of gold film with a thickness of 15-20nm on the surface of the sil...

Embodiment 3

[0065] A high-performance and long-life EPDM pump valve body material is made of the following substances by weight:

[0066] 50 parts of ethylene propylene rubber, 30 parts of nano-silica, 6 parts of calcium carbonate, 4 parts of epoxy soybean oil, 22 parts of plasticizer, 2.5 parts of activator, 1.5 parts of vulcanizing agent, 2 parts of accelerator, 8 parts of modification filler.

[0067] Further, the particle size of the nano white carbon black is 30-70nm.

[0068] Further, the particle size of the calcium carbonate is 600 mesh.

[0069] Further, the preparation method of the modified filler comprises the following steps:

[0070] 1) First put the silicon substrate into the acetone solution for 8 minutes of ultrasonic treatment, then take out the silicon substrate and dry it for later use;

[0071] 2) Put the silicon substrate treated in step 1) into a magnetron sputtering apparatus, and then coat a layer of gold film with a thickness of 15-20nm on the surface of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com