An intelligent industrial elevator and its operation method

An elevator and industrial technology, which is applied in the field of intelligent industrial elevators for AGV transportation and its operation, can solve problems affecting the operation efficiency of AGV, and achieve the effects of preventing safety accidents, reducing labor costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

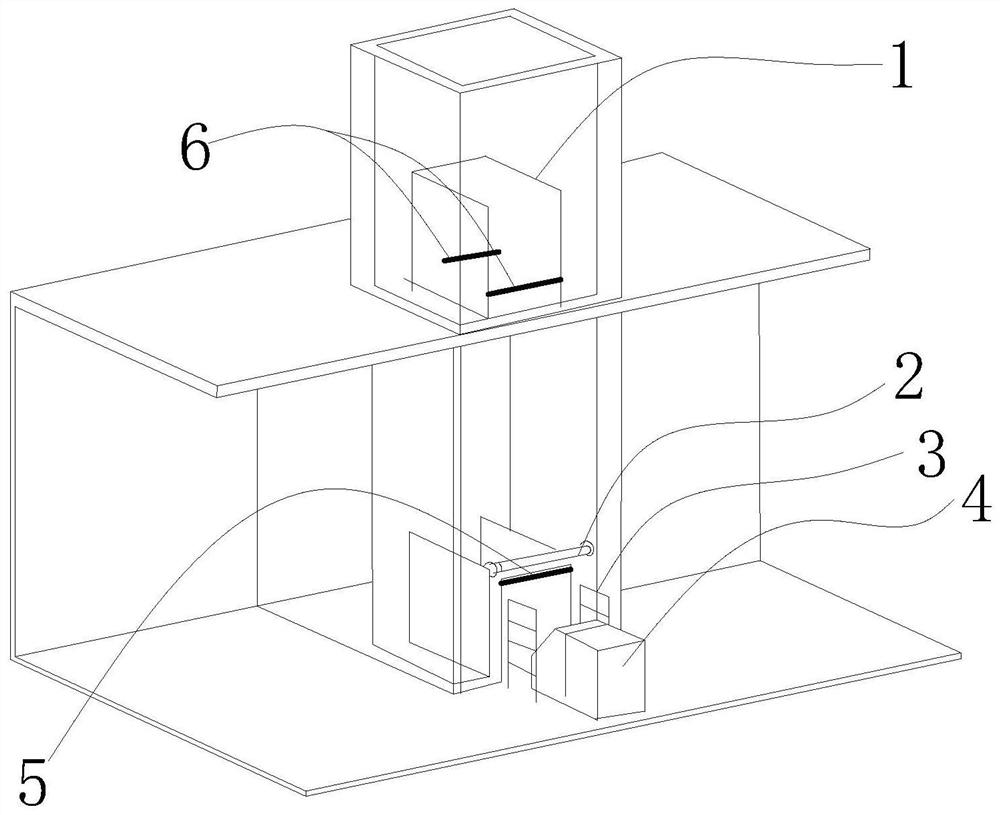

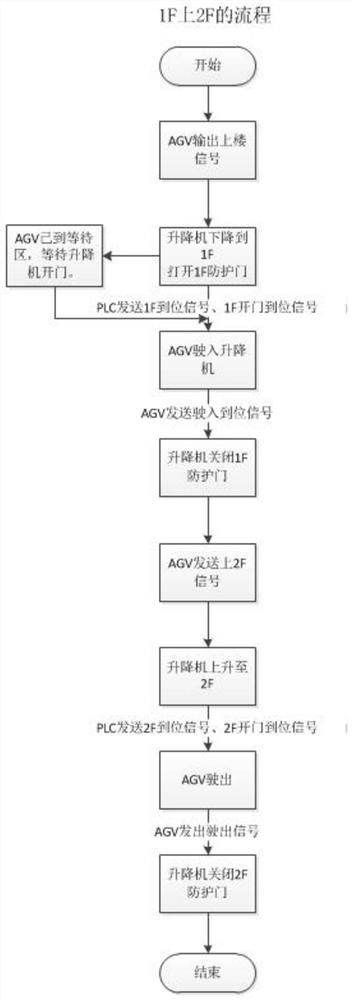

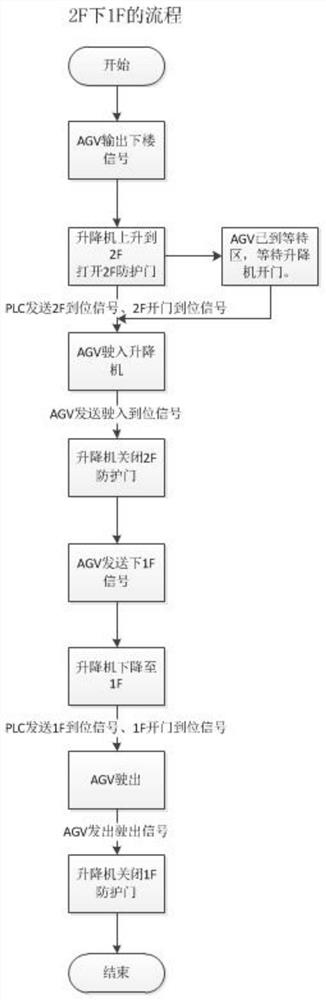

[0024] Example. An intelligent industrial elevator comprises a main body of an elevator system. A guardrail 3 that reduces the width of the landing door is arranged in front of the landing door 2 of the main body of the elevator system. The width of the guardrail matches the width of the AGV. When the AGV car body 4 enters the guardrail 3, the AGV car The maximum gap between the body 4 and the guardrail 3 is less than 200mm; a light curtain sensor 5 is arranged in front of the elevator floor door 2, an AGV arrival detection sensor 6 arranged in front and behind is arranged in the elevator car 1, and a human body sensor (can be Use thermal infrared human body sensor); the elevator central control system of the main body of the elevator system is connected with the workshop central control system thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com