Tidal power station multi-working-condition turbine based on contra-rotating dual-rotor permanent magnet motor

A permanent magnet motor, tidal power station technology, applied in electromechanical devices, electrical components, mechanical equipment and other directions, can solve the problems of inability to improve efficiency, unsatisfactory operating conditions, etc., to achieve high utilization of rotor core, conducive to stable flow, The effect of reducing the moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

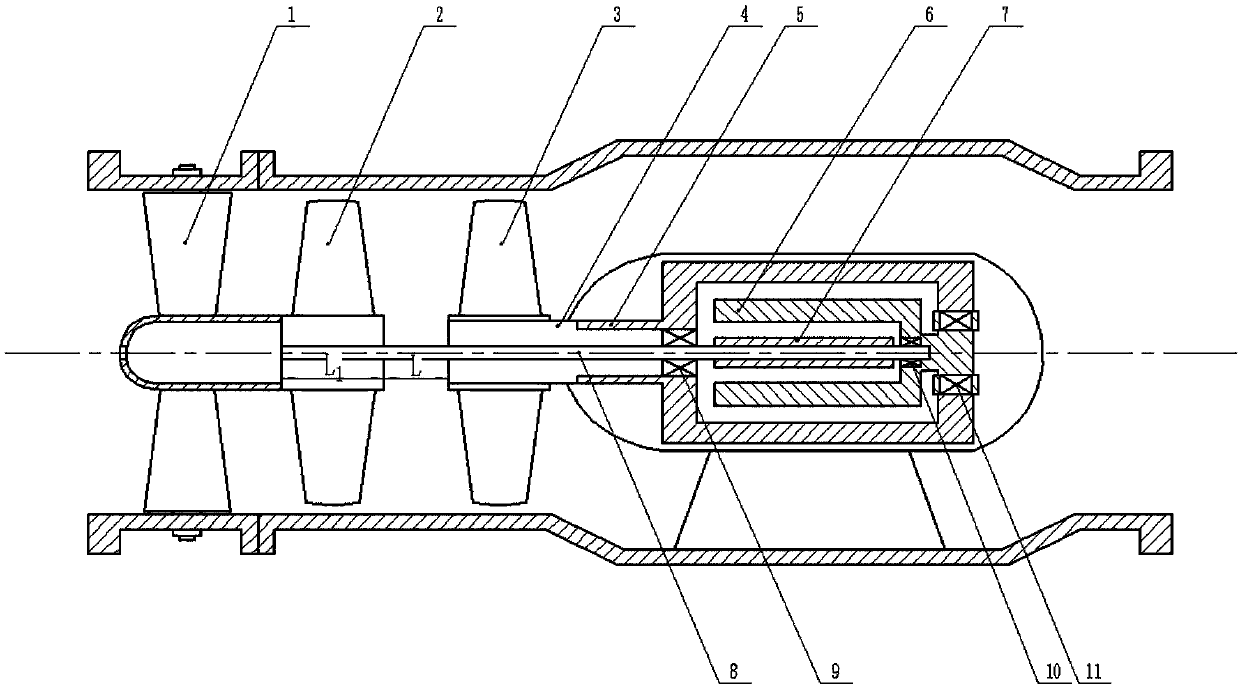

[0028] figure 1 Shown is an embodiment of a multi-working-condition turbine for a tidal power station based on a double-rotor counter-rotating permanent magnet motor of the present invention. The multi-working-condition turbine for a tidal power station based on a double-rotor counter-rotating permanent magnet motor includes movable Guide vane 1, runner one 2, runner two 3, hollow shaft 4, motor rotor one 5, motor stator 6, motor rotor two 7 and inner shaft 8, described turbine mainly consists of front movable guide vane 1, two One counter-rotating runner 2, runner 2 3 and motor part; runner 1 2 and runner 2 3 are installed axially symmetrically, movable guide vane 1 is arranged on the side of the counter-rotating wheel, and the motor part is arranged on the counter-rotating The other side of the wheel; the runner one 2 is connected with the motor rotor two 7 through the inner shaft 8; the runner two 3 is connected with the motor rotor one 5 through the hollow shaft 4; the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com