An anti-lock drill bit and a using method thereof

An anti-lock, drill bit technology, applied in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of high drilling resistance of the drill bit, low pile formation efficiency, construction loss, etc., to reduce drilling and lifting The effect of resistance, wide adaptability to stratum and high pile forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

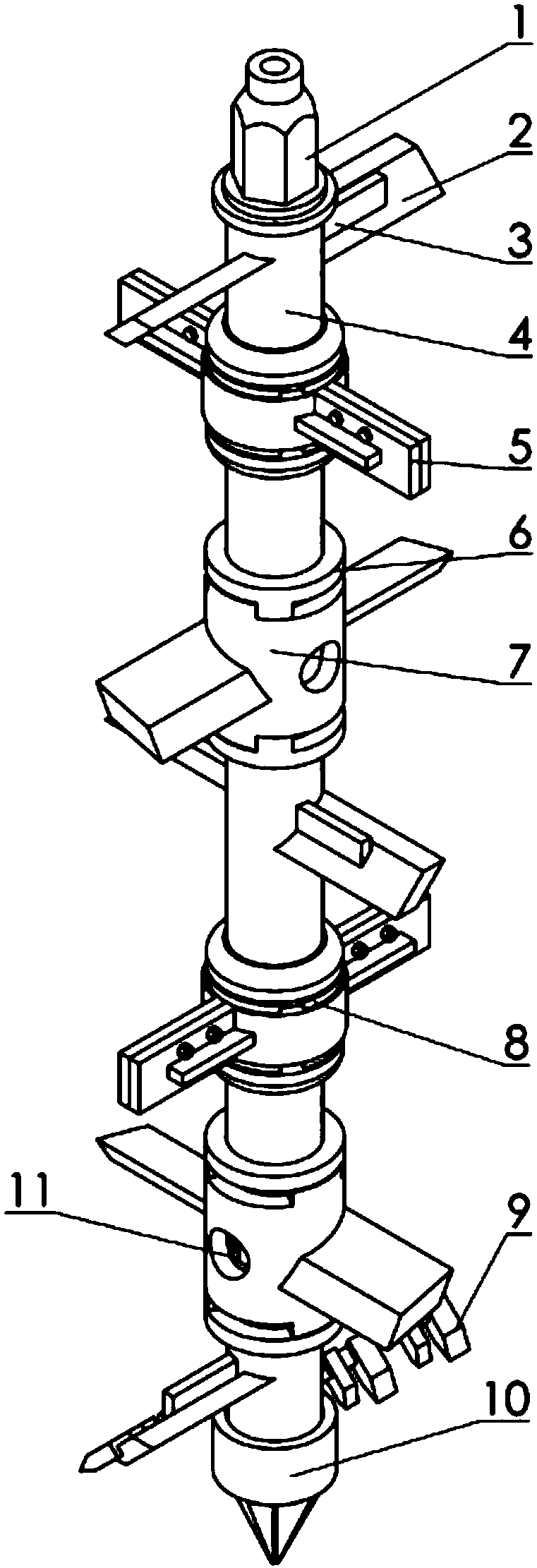

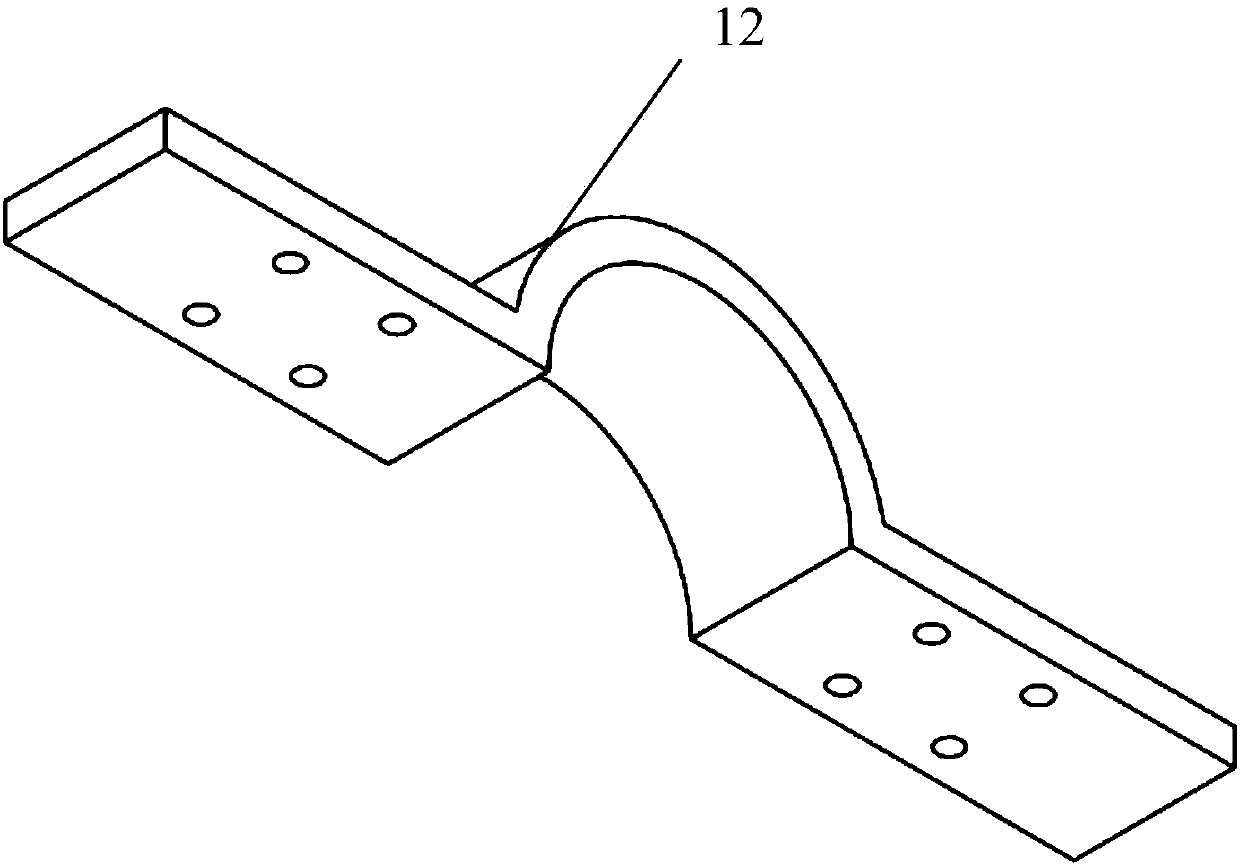

[0021] like figure 1 As shown, an anti-lock drill bit and its use method, the anti-lock drill bit mainly includes a hexagonal joint 1, a drill pipe 4, a stirring blade 2, a reinforcing rib 3, a wear-resistant tile 8, an anti-lock blade 5, and a spraying conversion Section 6, upper and lower stirring blades 7, picks 9, drill bit 10, grouting port 11, the hexagonal joint 1 is welded on the top of the drill pipe 4, and the stirring blades 2 are arranged in a cross on the drill pipe 4. The anti-lock blade 5 is composed of two Ω-shaped blades 12, which are connected with the drill pipe 4 by bolts through wear-resistant tiles 8, and the picks 9 are installed on the first stirring blade 2 of the drill pipe 4.

[0022] The present invention designs an anti-lock drill bit, and its use method is as follows: when the anti-lock drill bit is used for cement-soil mixing pile construction in cohesive soil, the whole drill bit rotates and drills downward, and the upper and lower mixing blades...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com