Electric vehicle power distribution box

A technology for electric vehicles and power distribution boxes, applied in vehicle components, electrical components, circuits or fluid pipelines, etc., can solve the problems of large temperature drift of shunt modules, low integration, difficult installation and maintenance, etc., to achieve enhanced The effect of resisting overload and load shock, improving integration and reliability, and reducing the difficulty of assembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

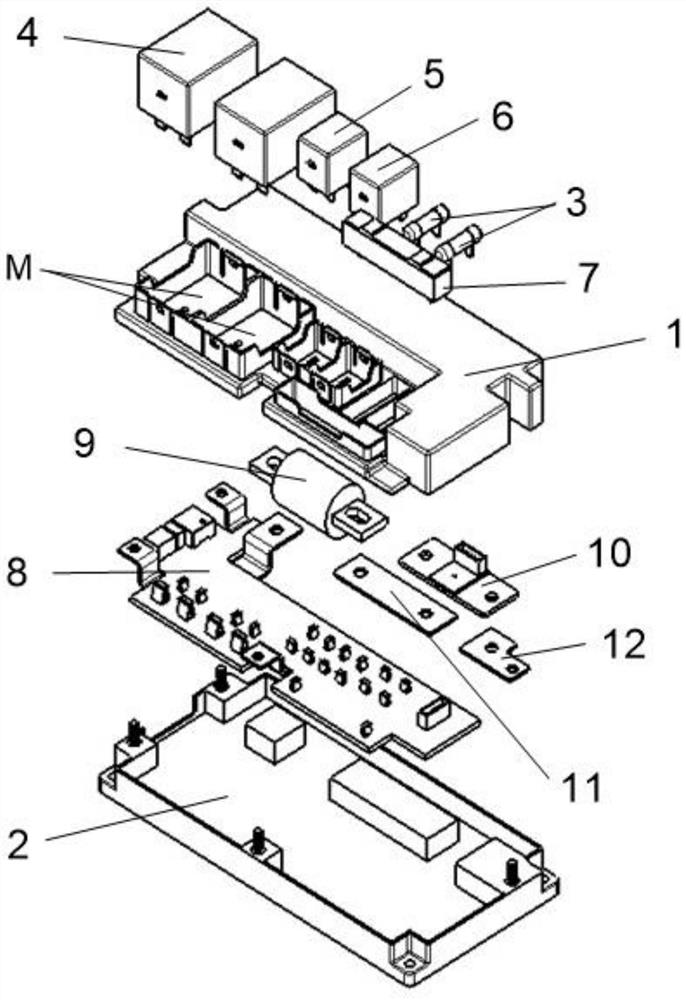

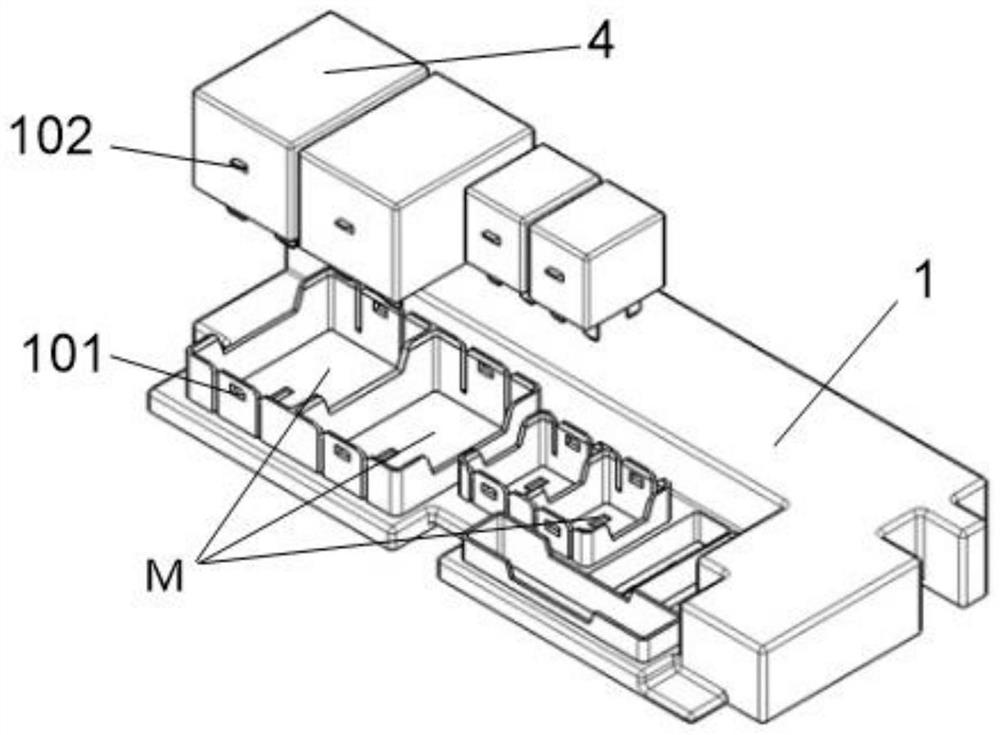

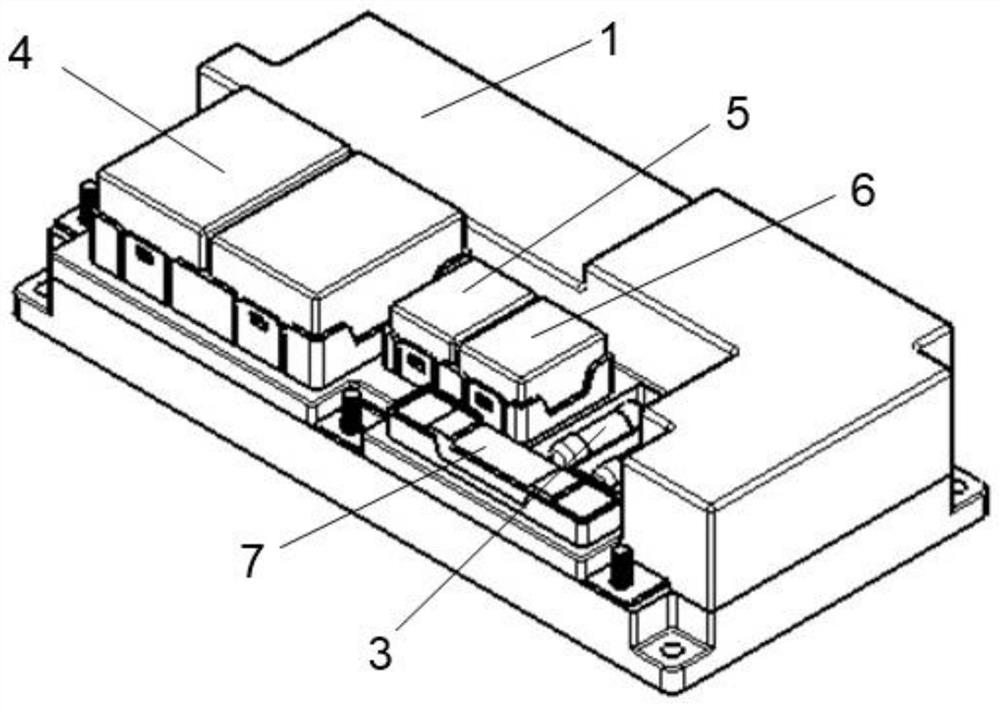

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. However, those skilled in the art know that the present invention is not limited to the drawings and the following embodiments.

[0024] An embodiment of the present invention proposes a power distribution box for an electric vehicle, including an upper case, a lower case, a plurality of relays and a PCB, the upper case is fixedly connected to the lower case, and the plurality of relays are fixedly installed On the upper case, the PCB is fixedly installed on the lower case, the upper case has a hollow structure, and the connection terminals of the plurality of relays pass through the hollow structure of the upper case and are inserted into the corresponding terminals on the PCB.

[0025] Specifically, refer to Figure 1a-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com