Sealing structure of automobile compressor

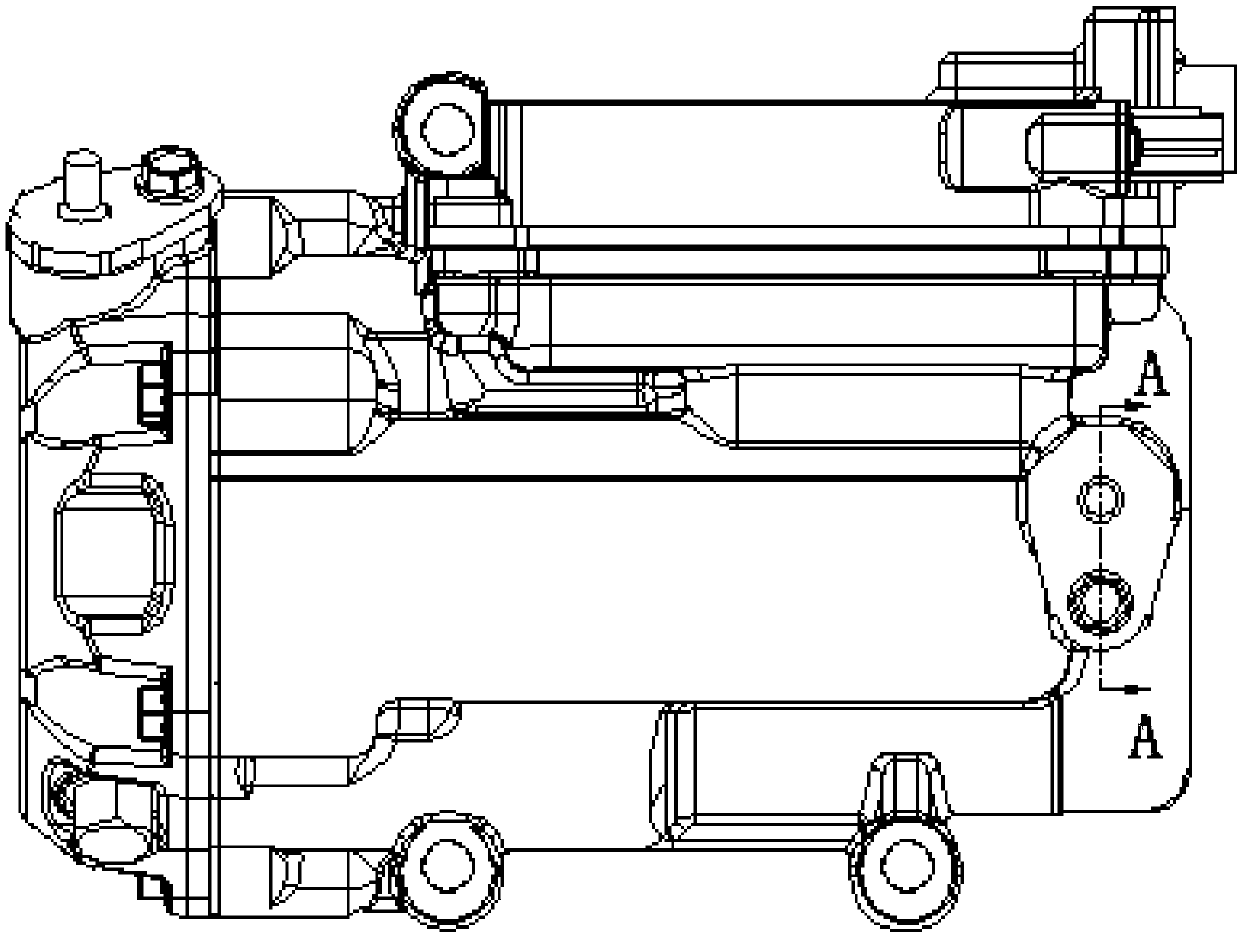

A technology of automobile compressor and sealing structure, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of waste, increase the cost of auxiliary materials, etc., and achieve the effect of prolonging life and preventing oil leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

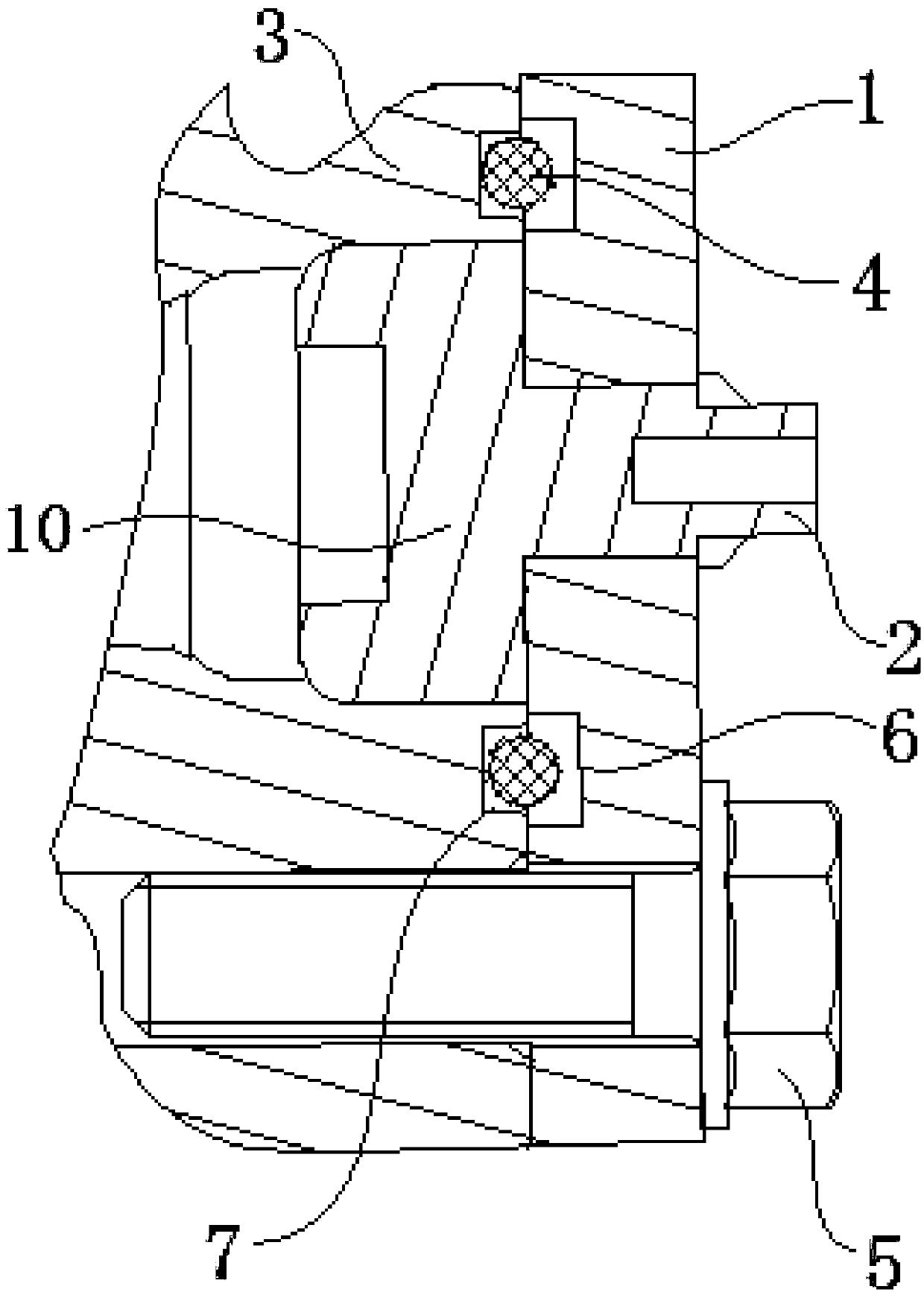

[0035] In order to achieve the purpose of the present invention, a sealing structure of an automobile compressor includes: a pressure plate 1 assembled with the body 3 of the compressor; an annular groove including a first annular groove 6 on the pressure plate 1 and a first annular groove 6 on the body 3 Two annular grooves 7, the cross-sectional profiles of the first annular groove 6 and the second annular groove 7 are square-shaped and their own length is circular; the sealing ring 4 is located in the annular groove, and the first annular groove 6 and the second annular groove 7 The depth and not less than the circle diameter of sealing ring 4 cross section.

[0036] The circles corresponding to the width centers of the first annular groove 6 and the second annular groove 7 are equal.

[0037] The beneficial effect of adopting the above-mentioned technic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com