Engine efficient axial rotation driving mechanism

A technology of axial rotation and drive mechanism, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of friction between the roller and the wall, large friction force, energy loss, etc., to reduce operating vibration, reduce volume, and reduce energy The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

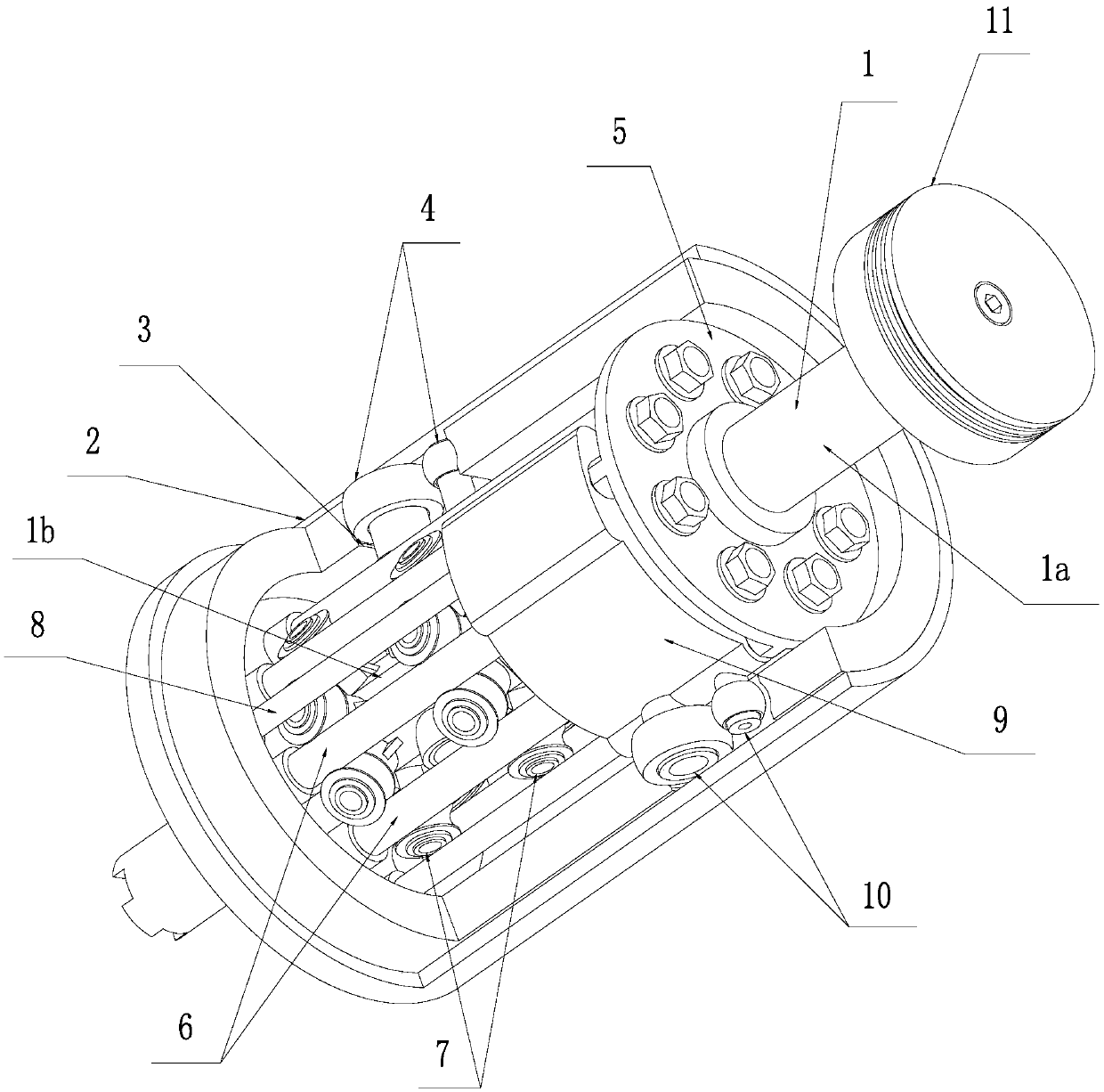

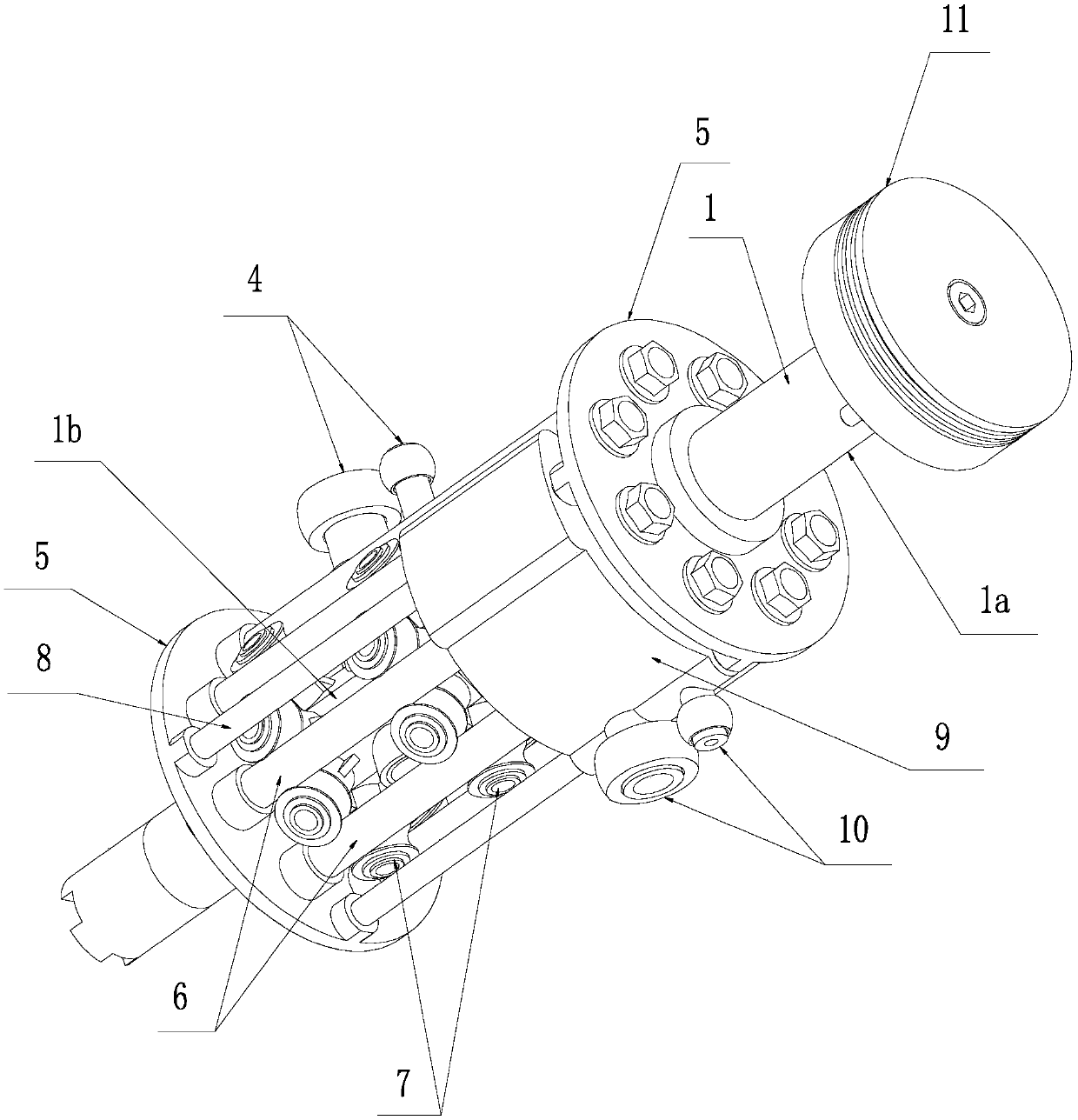

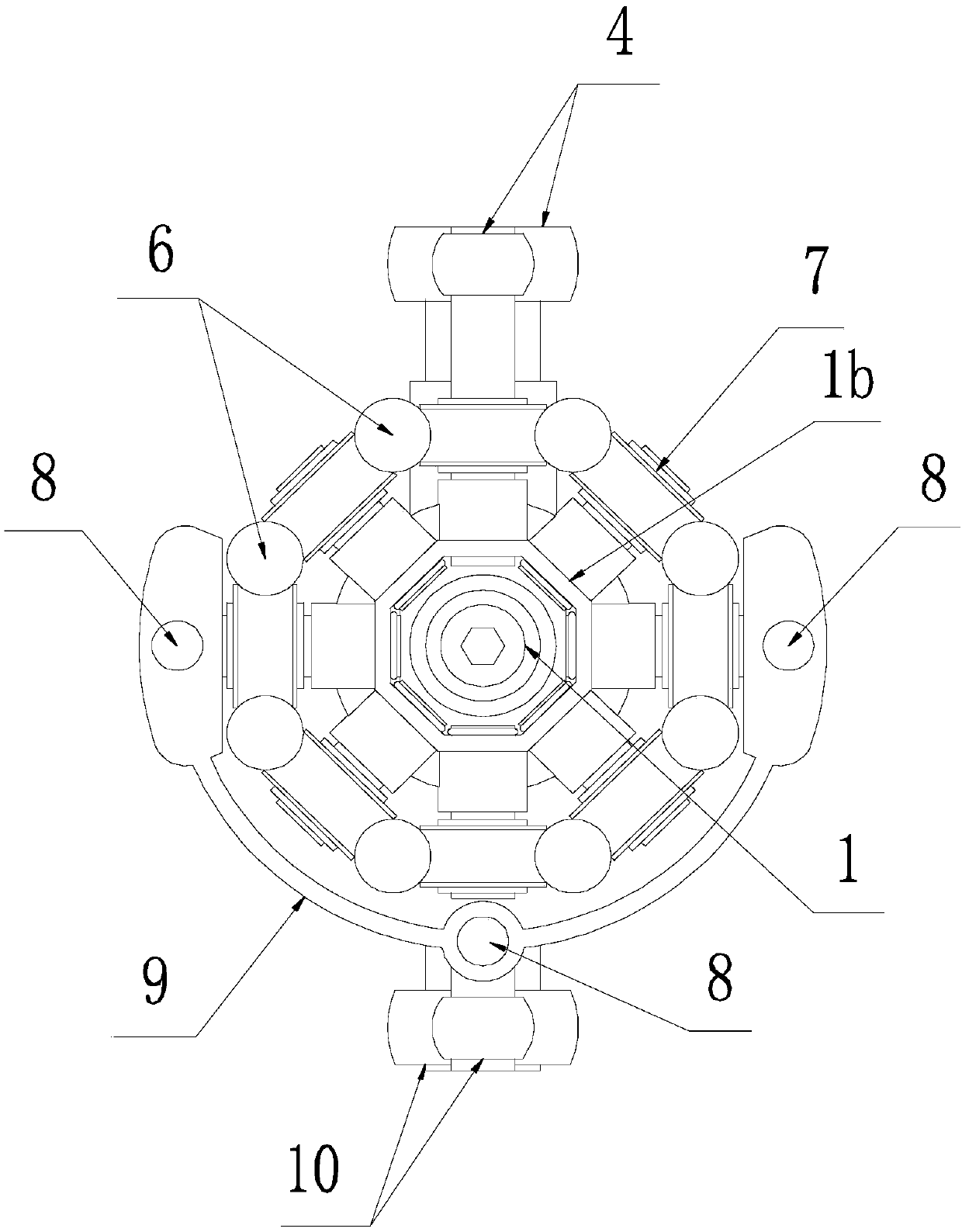

[0043] Example 1: Combining Figure 1~Figure 6 Shown is a specific embodiment of an engine high-efficiency axial rotation drive mechanism of the present invention.

[0044] As in known designs, it has an axial movement member 1 , a rotational movement member 2 and a guide mechanism. In this embodiment, the rotary movement member 2 is a cylinder located on the periphery of the axial movement member 1, and the axial movement member 1 consists of a rod-shaped part 1a for connecting with the piston 11 and a rod-shaped part 1a fixed on the rod-shaped The seat body 1b on the part 1a is jointly formed, see Figure 4 shown. The guide mechanism includes two brackets 5 located on both sides of the seat body 1b, and the two brackets 5 are both made into a disc shape. One of the brackets 5 is provided with a perforation for the rod-shaped part 1a to pass through, specifically as figure 1 and figure 2 shown.

[0045] In this embodiment, an inclined closed-loop drive groove 3 is prov...

Embodiment 2

[0052] combine Figure 7~Figure 12 Shown is another specific embodiment of an engine high-efficiency axial rotation drive mechanism of the present invention.

[0053] Like Embodiment 1, it has an axial movement component 1, a rotation movement component 2 and a guide mechanism. In this embodiment, the rotary movement member 2 is also a cylinder located on the periphery of the axial movement member 1, and the axial movement member 1 is also composed of a rod-shaped part 1a for connecting with the piston 11 and a rod-shaped part 1a fixed on the rod-shaped The seat body 1b on the part 1a is jointly formed, see Figure 10 shown. The guide mechanism includes two brackets 5 located on both sides of the seat body 1b, and the two brackets 5 are also made into disc shapes. One of the brackets 5 is provided with a perforation for the rod-shaped part 1a to pass through, specifically as Figure 7 and Figure 8 shown.

[0054] The difference between this embodiment and Embodiment 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com