Pile guiding device capable of reducing noise during pile sinking construction

A noise and pile sinking technology, which is applied in the direction of sheet pile walls, foundation structure engineering, buildings, etc., can solve the problems of force loss, impact on construction efficiency, and impact on the surrounding environment of the construction area, so as to reduce noise and improve pile sinking efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

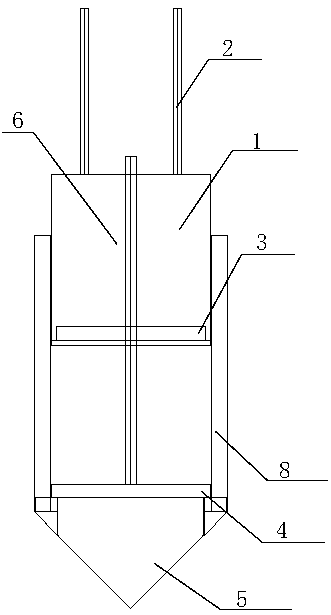

[0027] Such as Figure 1-4 As shown, a pile-leading device that can reduce the noise of pile sinking construction includes a hammer 1 and a pile head 5. The hammer 1 is hoisted in the cavity of the pile 8 through the sling 2, and the sling 2 is pulled by an external force to make the hammer 1 in the hollow of the pile 8. Move up and down in the cavity; a protrusion is provided in the bottom cavity of the pile 8, and the protrusion is arranged around the inner diameter of the pile cavity; the tip of the pile head 5 is tapered, protruding from the bottom of the pile 8, and the gasket 4 is arranged on the top, The external dimensions of the sheet 4 are slightly larger than the top size of the pile head 5, and are matched with the protrusions. The pile head 5 is clamped on the protrusion in the pile cavity through the gasket 4; The other end of the rod 6 passes through the axial direction of the hammer 1 and is connected to the outer part, which is used to pull the pile head out o...

Embodiment 2

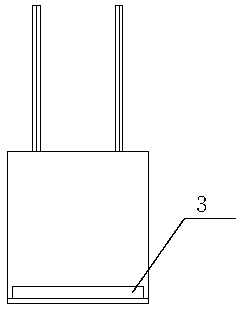

[0031] Such as Figure 5 As shown, a pile-leading device that can reduce the noise of pile sinking construction includes a hammer 1 and a pile head 5. The hammer 1 is hoisted in the cavity of the pile 8 through the sling 2, and the sling 2 is pulled by an external force to make the hammer 1 in the hollow of the pile 8. Move up and down in the cavity; a protrusion is provided in the bottom cavity of the pile 8, and the protrusion is arranged around the inner diameter of the pile cavity; the tip of the pile head 5 is tapered, protruding from the bottom of the pile 8, and the gasket 4 is arranged on the top, The external dimensions of the sheet 4 are slightly larger than the top size of the pile head 5, and are matched with the protrusions. The pile head 5 is clamped on the protrusion in the pile cavity through the gasket 4; The other end of the rod 6 passes through the axial direction of the hammer 1 and is connected to the outer part, which is used to pull the pile head out of ...

Embodiment 3

[0035] Such as Figure 6 As shown, a pile-leading device that can reduce the noise of pile driving construction is similar to the structure in Embodiment 1, and will not be repeated here.

[0036] When it is necessary to sink piles after connecting multiple piles, flanges can be connected at the junction of piles 8 and 8, and a hollow load-bearing cylinder 9 with a closed inner hollow and outer wall is arranged between the gasket 4 and the pile head 5. The load-bearing cylinder 9 needs to match the inner diameter of the pile cavity, and its height needs to be just at the joint of the flange. The gasket 4 is just placed on the upper end surface of the pile flange above, and the suspender passes through the axis of the hollow load-bearing cylinder 9. By hammering the gasket on the hollow load-bearing cylinder 9, the gasket and the pile head drive the pile to move downward to realize pile sinking.

[0037] The two-section piles are connected together by flanges. When sinking the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com