A kind of preparation method and application of resistant starch with amylase inhibitory active group

An amylase inhibition and resistant starch technology is applied in the field of preparation of new resistant starch, which can solve the problems of high fiber content, insufficient fiber content, and inability to diet for diabetic patients in resistant starch, and achieve the effect of high hypoglycemic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

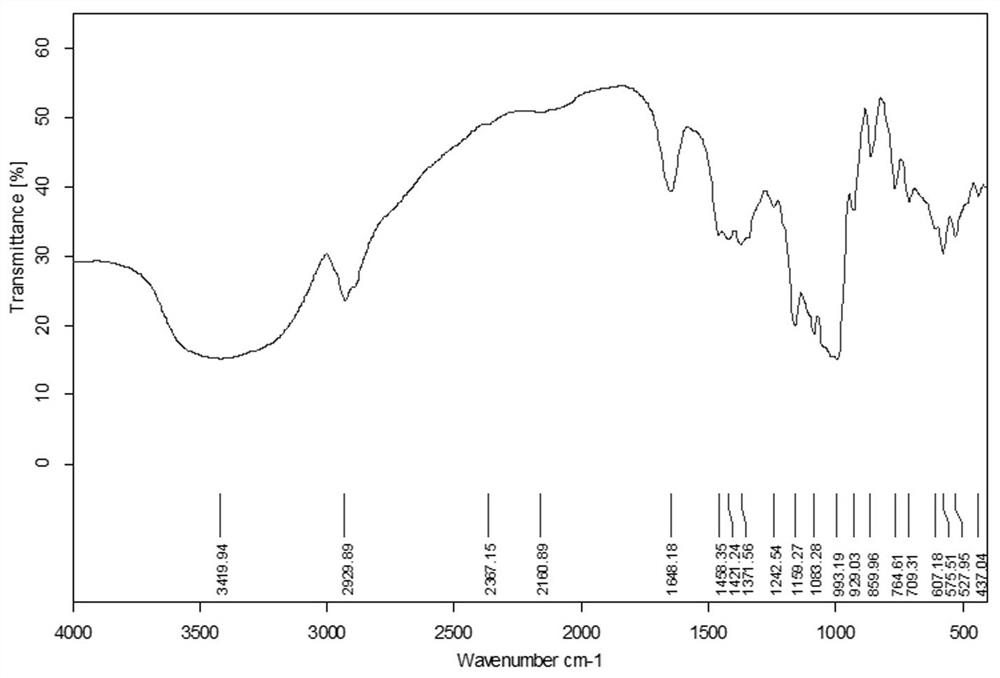

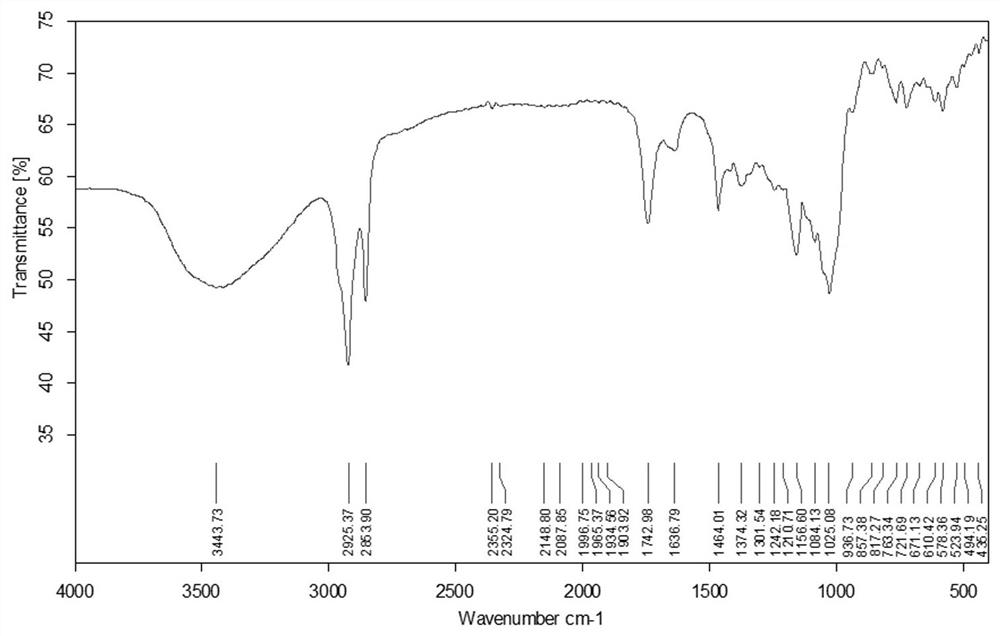

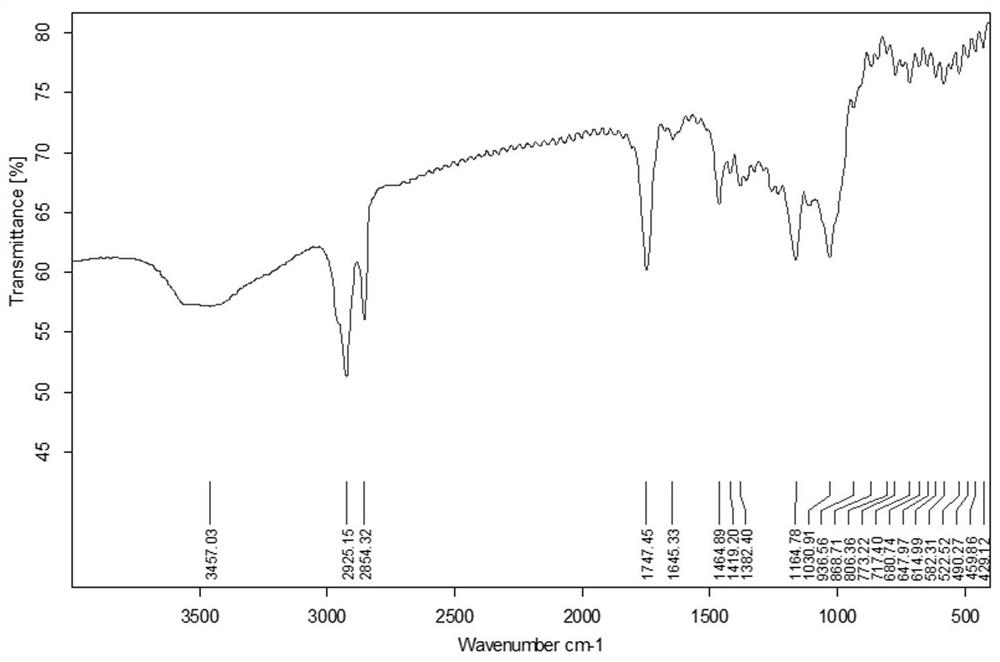

Image

Examples

Embodiment 1

[0027] A method of preparation of novel resistive starch having amylase inhibiting active groups, including the steps of:

[0028] (1) 0.1 mol of palmitic acid was added to a 150 ml of three-necked flask, and the 67 ° C water bath was added to dissolve, stirred with 0.16 mol (11.6 mL) of sulfoxide, 30 min was added, and stirring was stirred for 4 hours, and after stopping the reaction, The remaining chlorinated sulfoxide was recovered under reduced pressure to obtain palmitrate acid chloride, which poured into a dry 100 mL dropping funnel, mixed, closed backup;

[0029] (2) In a three-mouth flask equipped with a stirrer and reflux condensed water, 3.38 g of potato crosslinking starch and 30 ml of pyridine, stirred so much, activated at 95 ° C for 1 h, adjust the reaction temperature to 85 ° C, 35 ml of palmitrate acid chloride, 30 min was added, 2 h, cooled to room temperature, the product was added to anhydrous ethanol, stirred, stirred, filtered, filtered, washed with ethanol an...

Embodiment 2

[0033] A method of preparation of novel resistive starch having amylase inhibiting active groups, including the steps of:

[0034] (1) 0.1 mol of the lauic acid was added to a 150 ml of three-necked flask, and the 69 ° C water bath was heated to dissolve, stirred with 0.16 mol (11.6 mL) of sulfoxide, stirred at 35 min, and stirred for 4.5 h, and after stopping the reaction, The remaining chlorinated sulfoxide was recovered under reduced pressure to obtain a laurine acidic acid chloride, which poured into a dry 100 mL dropping funnel, mixed, closed backup;

[0035] (2) In a three-mouth flask equipped with a stirrer and reflux condensed water, 3.38 g of potato crosslinking starch and 30 ml of pyridine, stirred so much, activated at 95 ° C for 1 h, adjust the reaction temperature to 85 ° C, Add 35 ml of lauicy chloride, 30 min was added, 2 h, cooled to room temperature, and the product was added to anhydrous ethanol, stirred, stirred, filtered, washed with ethanol and benzene, and fi...

Embodiment 3

[0038] A method of preparation of novel resistive starch having amylase inhibiting active groups, including the steps of:

[0039] (1) 0.1 mol of bishanedate was added to a 150 ml of tri-necked flask, 65 ° C water bath was heated to dissolve, stirred with 0.16 mol (11.6 mL) of sulfoxide, stirred at 28 min, continued to stir 3.5 h, stopping the reaction The remaining chloride is recovered by decompression, and the acid chloride is obtained, and the dried 100 ml of drip funnel is poured into the dry 100 ml of drip funnel;

[0040] (2) In a three-mouth flask equipped with a stirrer and reflux condensed water, 3.38 g of potato crosslinking starch and 30 ml of pyridine, stirred so much, activated at 95 ° C for 1 h, adjust the reaction temperature to 85 ° C, 35 ml of myrista chloride was added dropwise, 30 min was added, 2 h, cooled to room temperature, the product was added to anhydrous ethanol, stirred, epigelation, filtrate, wash filtration with ethanol and benzene, and finally used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com