Method for detecting a malfunction of an ultrasonic fluid sensing system

A sensing system, ultrasonic technology, applied in the direction of measuring ultrasonic/sonic/infrasonic waves, using sound waves/ultrasonic/infrasonic waves for material analysis, processing detection response signals, etc., can solve the problem of undisclosed detection and mass transducer-dependent error measurement Results and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

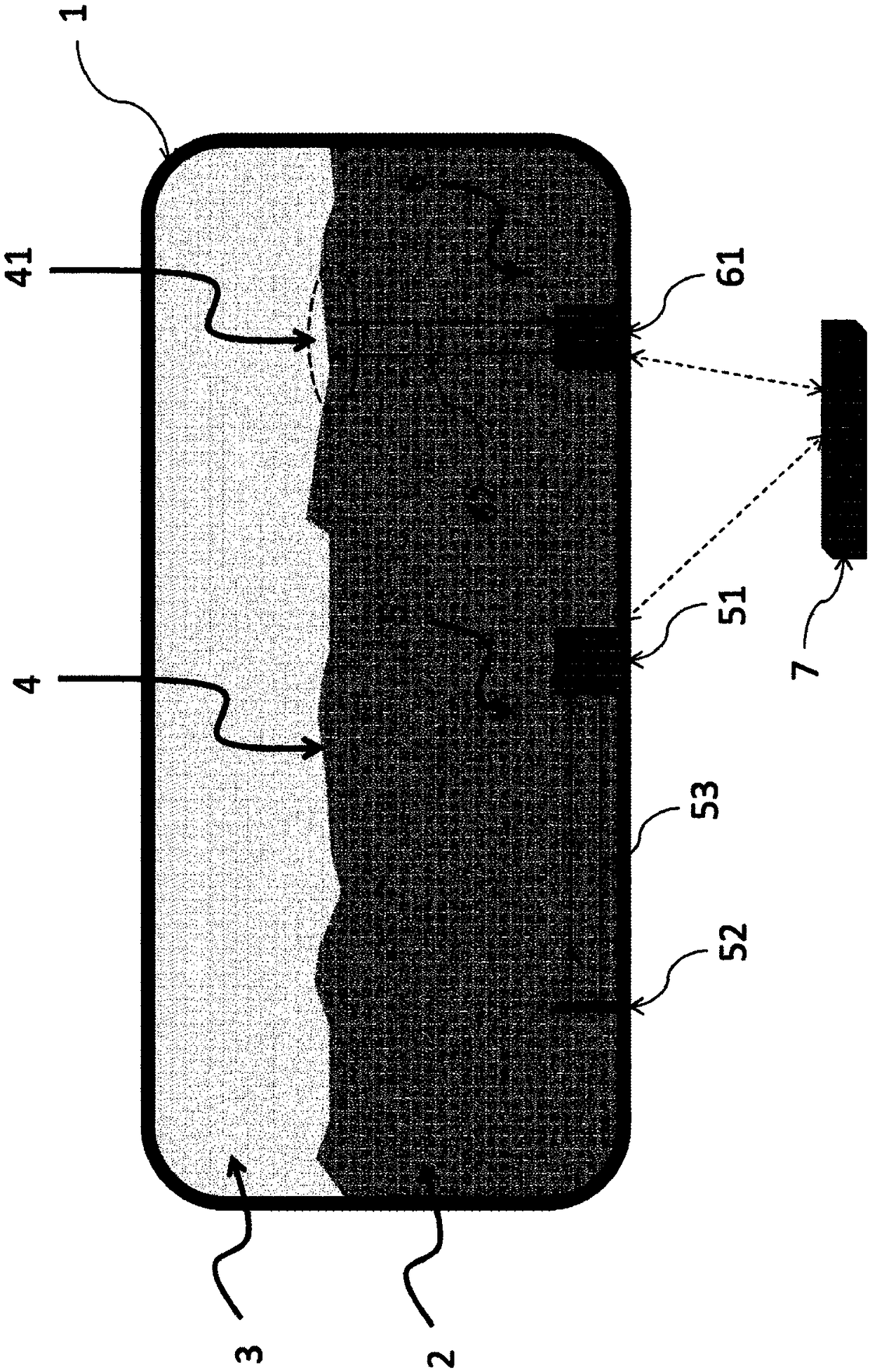

[0062] figure 1 One exemplary embodiment of a vehicle fluid storage system is shown. Such as figure 1 As shown in the example, the fluid storage system includes:

[0063] - a tank 1 for storing a fluid mixture 2, for example an aqueous urea solution; and

[0064] - A fluid dual sensing system according to a specific embodiment of the invention.

[0065] When the fluid mixture 2 is present in the tank 1, the space not occupied by the fluid mixture will be filled with the gas mixture. This space is called "vapor space"3. The interface of the fluid mixture with the vapor space is marked 4 .

[0066] exist figure 1 In the example of , the fluid dual sensing system is designed to provide two physical quantities: a physical quantity indicative of the concentration of components of the fluid mixture in the tank and a physical quantity indicative of the level of the fluid mixture in the tank. More precisely, the dual sensing system includes:

[0067] - a first ultrasound subsy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com