Novel automatic bearing machining equipment

A bearing processing and automatic technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of high labor cost, cost reduction, complex mold, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be further described in detail below. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

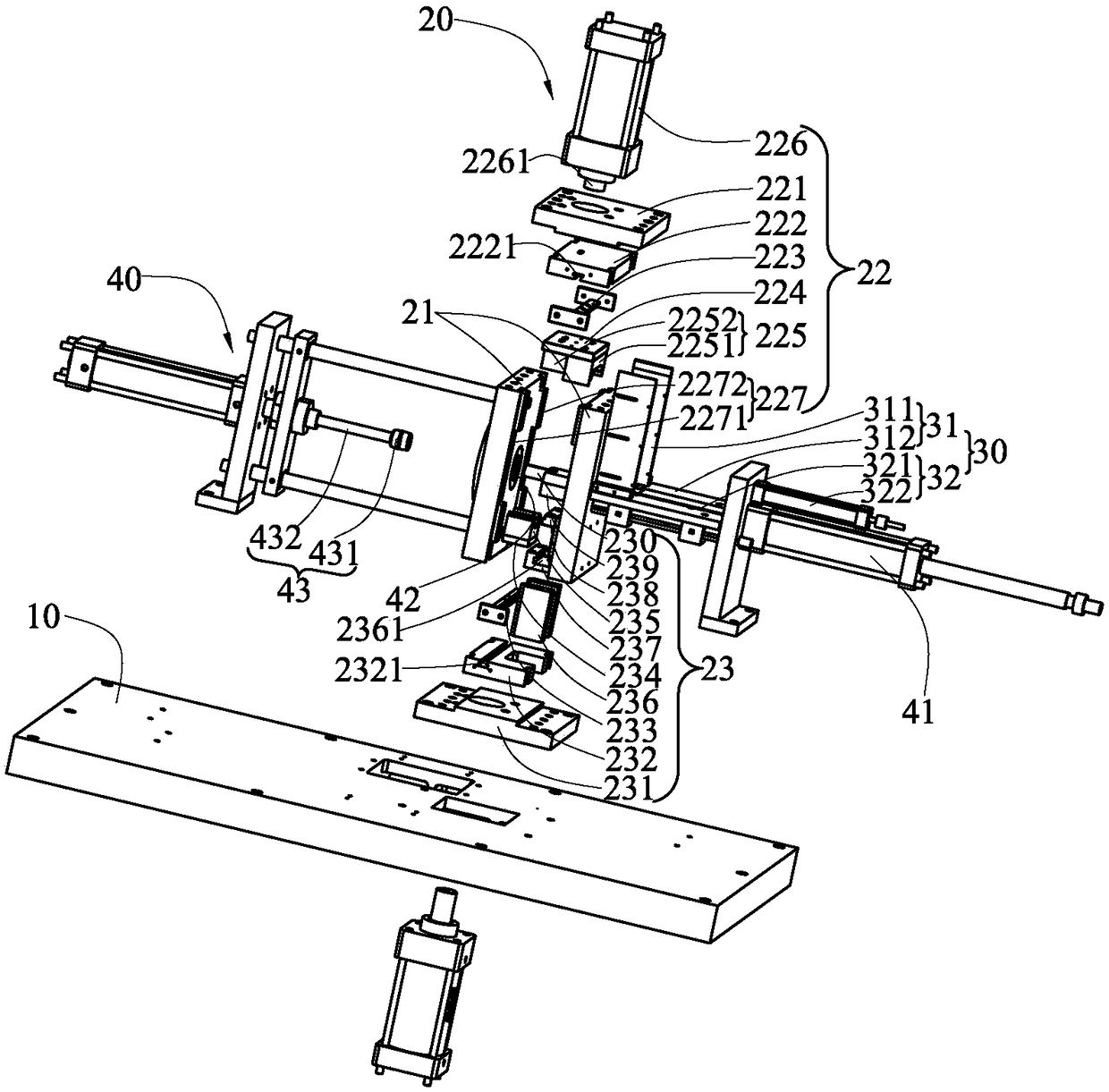

[0020] like Figure 1 to Figure 3 As shown, it is a structural schematic diagram of the new automatic bearing processing equipment provided by the present invention. The new automatic bearing processing equipment includes a frame 10, a rolling mechanism 20 arranged on the frame 10, a feeding mechanism 30 arranged on the frame 10, and a rolling mechanism 20 arranged on the frame 10. The shaping mechanism 40 on the top, and a control device 50 that controls the orderly operation of the rolling mechanism 20, the feeding mechanism 30, and the shaping mechanism 40. It is conceivable that, as a device for processing shaft sleeves, it also includes other functional modules, such as installation components, motor fixing com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com