Flat cable lifting device for stacker

A flat cable and stacker technology, applied in the direction of lifting devices, etc., can solve the problems of interfering with the operation of other parts, reducing the service life of cables, and the failure of the cargo platform to work normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

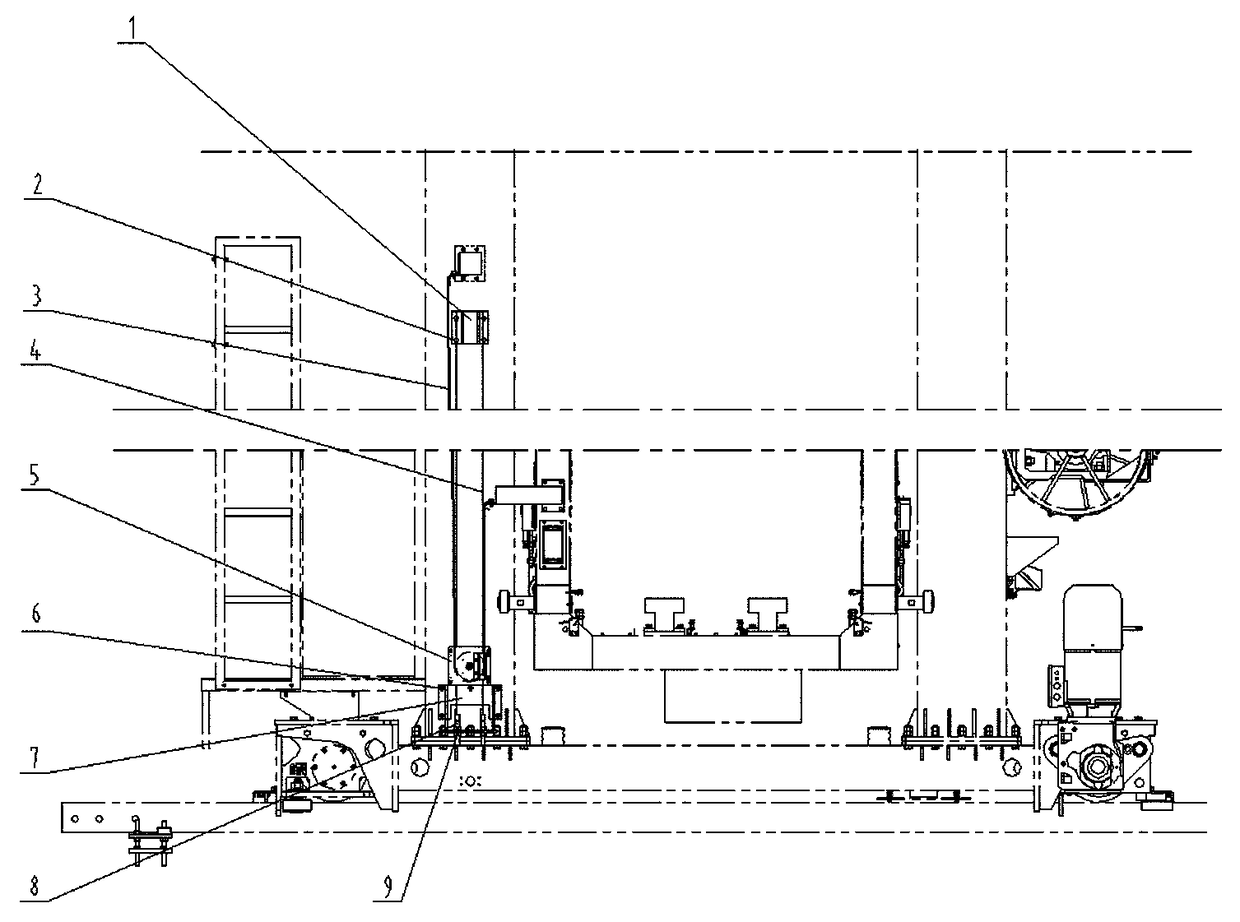

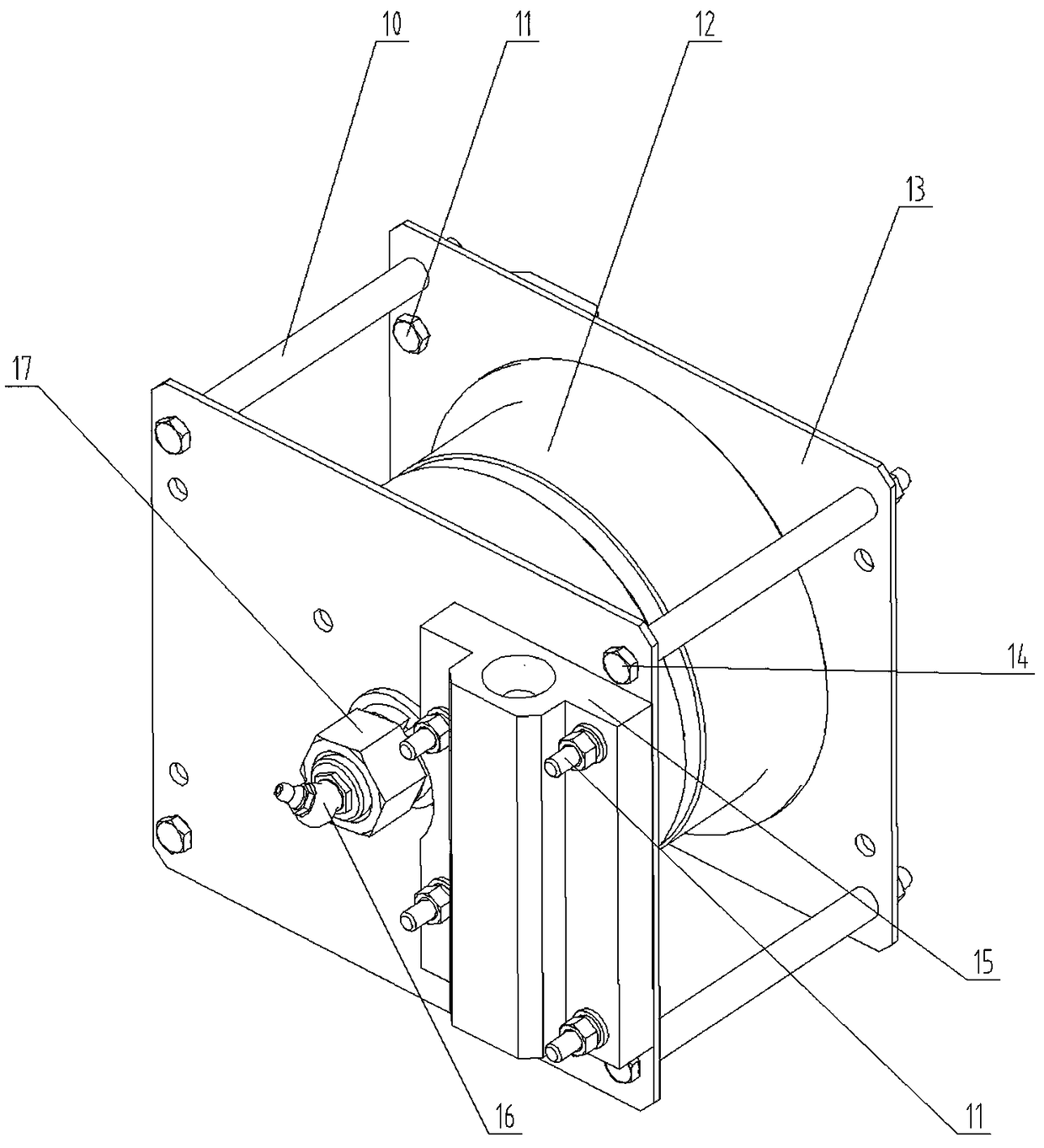

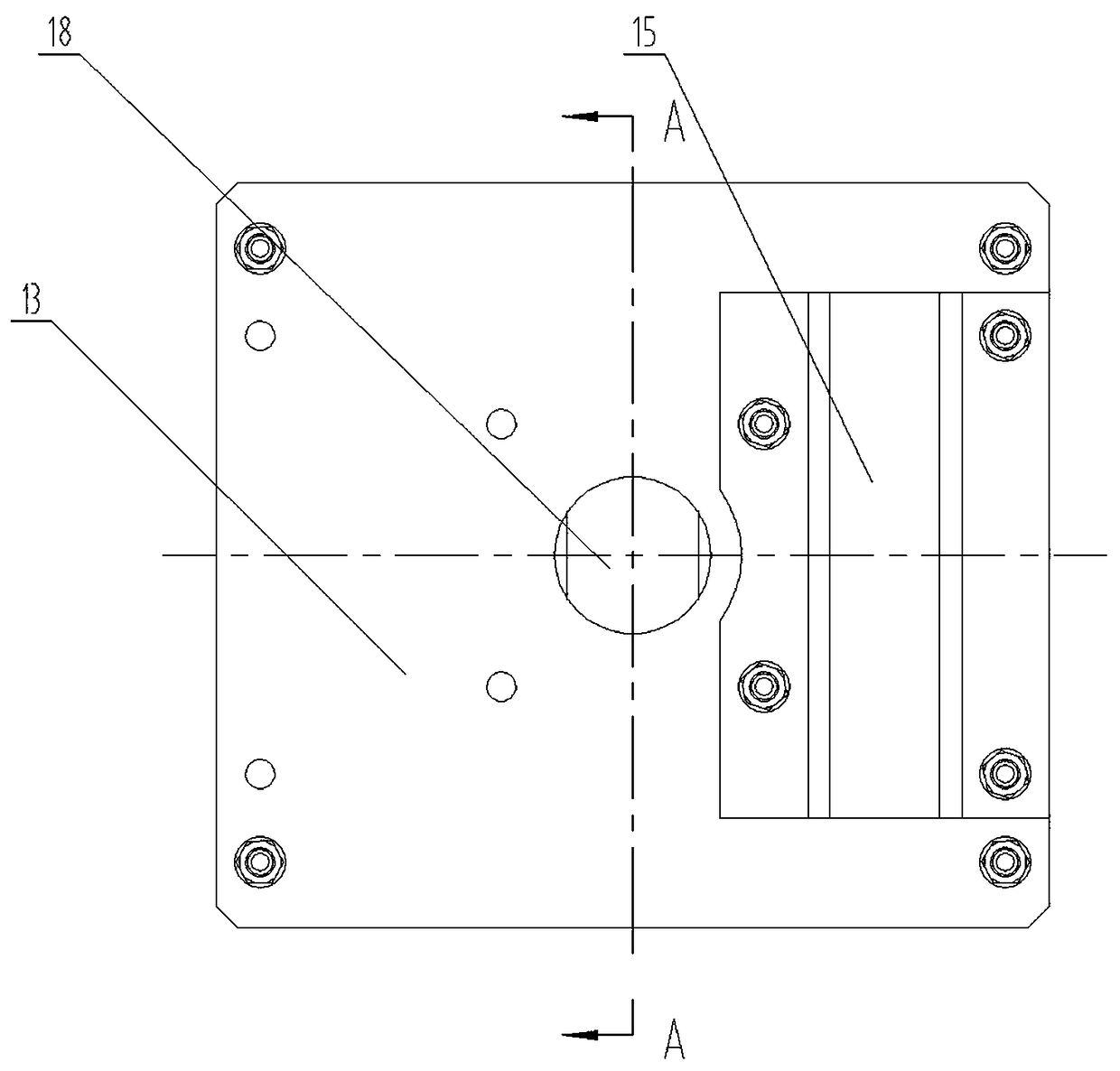

[0013] As shown in the figure, the present invention mainly includes bracket (1) 1, screw 2, flat cable 3, steel wire rope 4, lifting wheel assembly 5, screw 6, bracket (2) 7, pull rod 8 from top to bottom; bracket (1) 1 and support (two) 7 are installed in the middle lower end position of stacker column 24 with screw 2,6 respectively, and support (two) 7 installations can fix the pull bar 8 of wire rope 4, and fix with nut. The lifting wheel assembly 5 includes a pulley mounting sleeve 10, bolts 11, pulleys 12, pulley mounting plates 13, bolts 14, wire rope guide sleeves 15, oil cups 16, nuts 17, pulley shafts 18, bearings 19, pulley shaft spacers 20 The pulley 12 is installed on the pulley shaft 18 through the deep groove ball bearing 19, the pulley shaft spacer 20 of the compression bearing 19 is installed at the two ends of the pulley shaft 18, and the pulley shaft 18 is inserted in the center position between the two pulley mounting plates 13, The leftmost end is fixed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com