Cylindrical transport frame for transporting steel forms

A technology of transport racks and steel formwork, applied in the field of transport racks, can solve the problems of difficult products being delivered to the final destination and poor surrounding protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

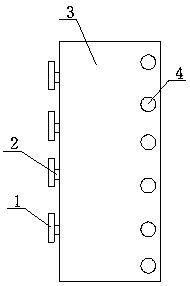

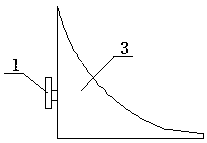

[0012] like figure 1 and figure 2 As shown, the columnar transport frame used for transporting steel formwork includes a disc 1, a support frame 2, an arc frame 3 and a through hole 4, and the arc frame 3 is a triangular prism-like structure with one side concave. A plurality of support frames 2 are fixed on a rectangular surface of the arc frame 3 , the disk 1 is placed on the support frame 2 , and a plurality of through holes 4 are opened on one side of the concave surface of the arc frame 3 .

[0013] The disc 1 is parallel to the arc frame 3 .

[0014] The through holes 4 are located on the same straight line and arranged at equal intervals.

[0015] When in use, the arc frame 3 is placed on the car, the fastening screws are fixed through the through holes 3, and the disc 1 and the car wall are ensured to fit together, and the columnar part is placed on the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com