Preparing and stirring device for pickled vegetables

A technology for pickles and mixers, which is applied to mixer accessories, transportation, packaging, and dissolution. It can solve the problems of potential safety hazards, pickles spilling outside the outlet bucket, and loss, so as to eliminate potential safety hazards and increase mixing efficiency. , the effect of avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

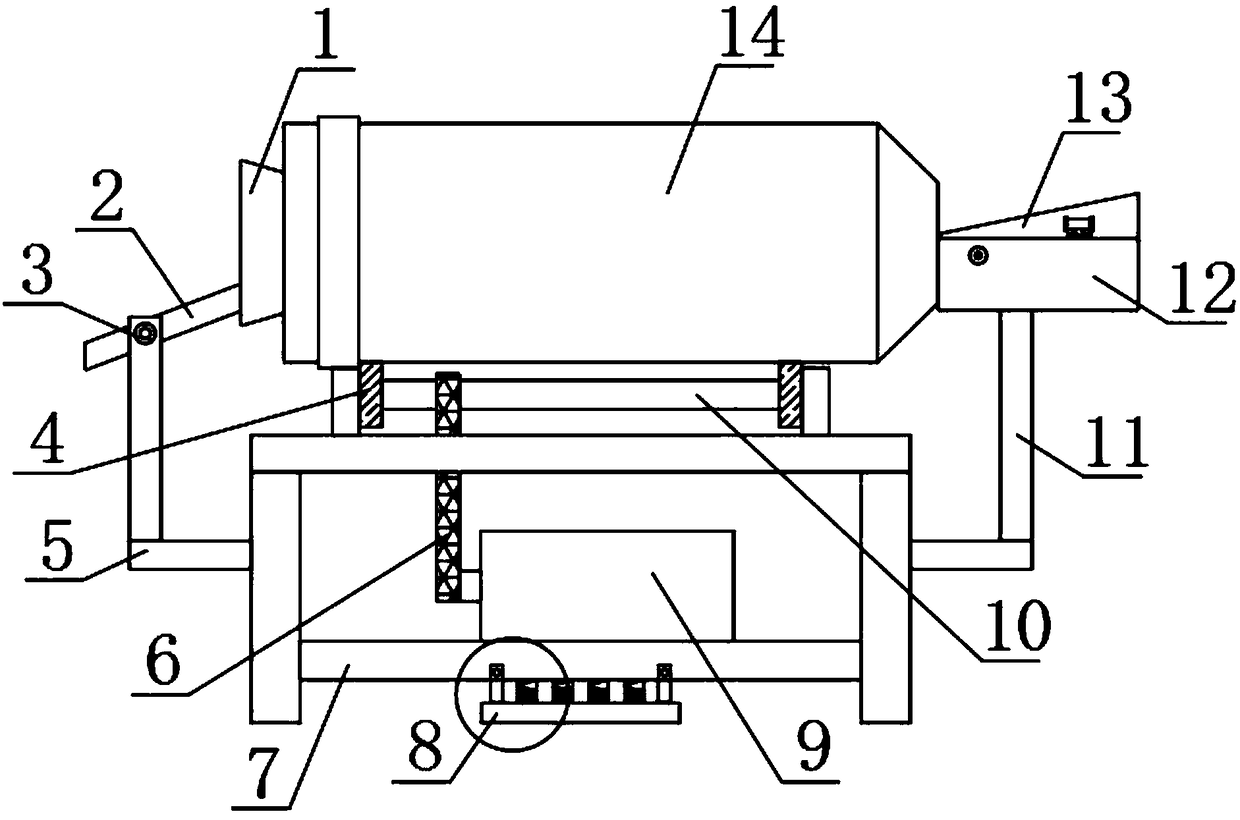

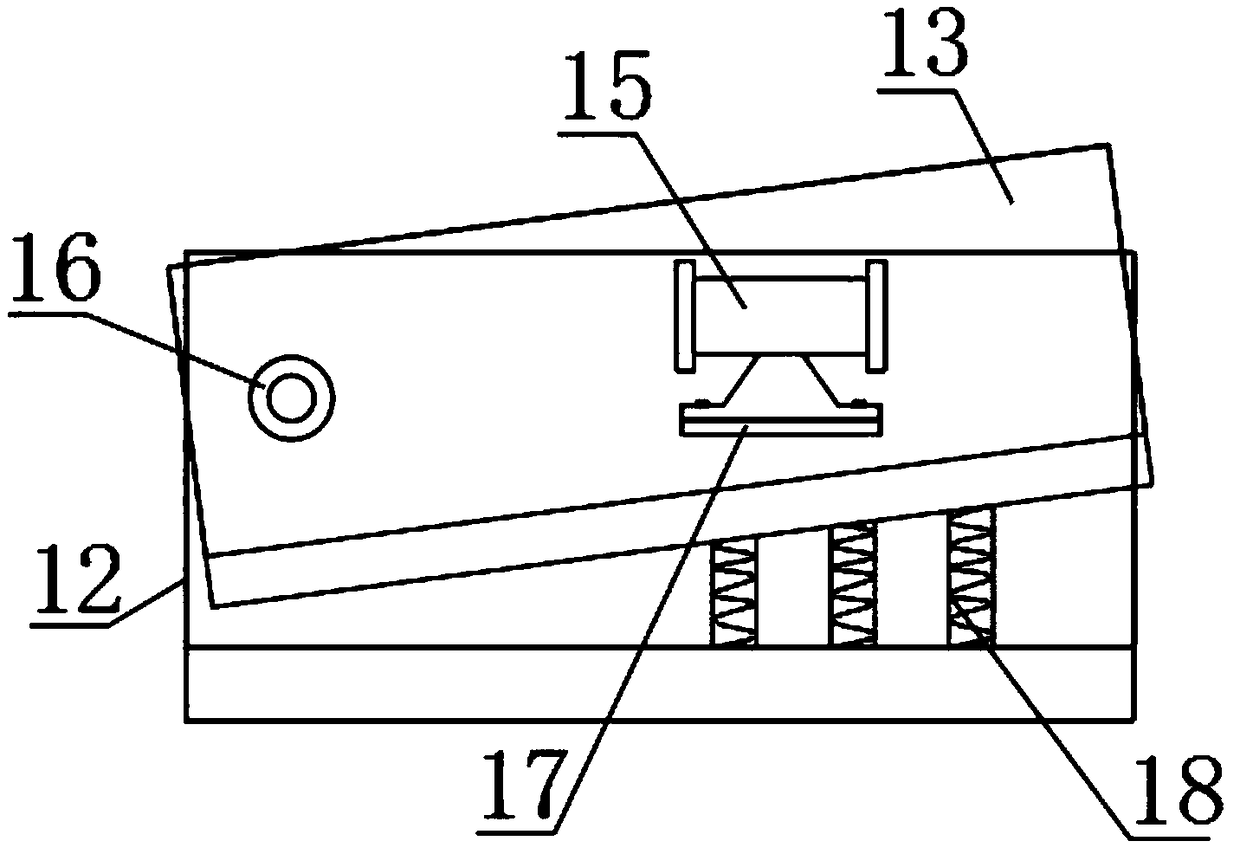

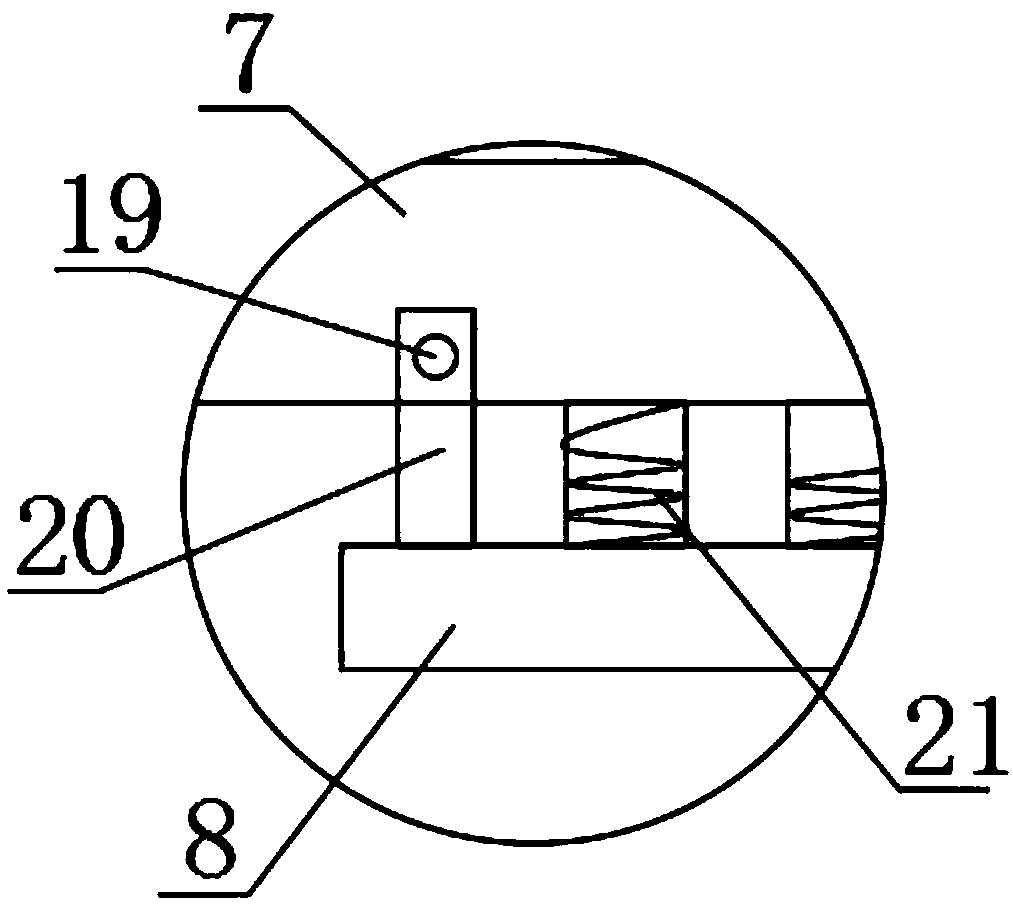

[0021] see figure 1 , figure 2 , image 3 and Figure 4 , the present invention provides a kind of technical scheme: pickles preparation and mixing device, comprise pickles mixing machine body, also comprise feeding mechanism, discharge mechanism and cushioning mechanism, pickles mixing machine body include mixing bucket 14 and mixing bucket 14 bottoms Driven wheel 4, feeding mechanism is installed on one end of mixing bucket 14, and feeding mechanism comprises the feeding inner bucket 13 of mixing bucket 14 one ends, and the bottom of feeding inner bucket 13 is provided with fixed outer bucket 12, and feeding inner bucket 13 and The connection position of the fixed outer bucket 12 is provided with a second rotating clamp shaft 16, the outer surface of the feeding inner bucket 13 is provided with a vibrating motor 15, and the bottom of the vibrating motor 15 is provided with a motor base 17, and the feeding inner bucket 13 is connected to the fixed outer bucket. Vibration ...

Embodiment 2

[0027] see figure 1 , figure 2 , image 3 and Figure 4 , the present invention provides a kind of technical scheme: pickles preparation and mixing device, comprise pickles mixing machine body, also comprise feeding mechanism, discharge mechanism and cushioning mechanism, pickles mixing machine body include mixing bucket 14 and mixing bucket 14 bottoms Driven wheel 4, feeding mechanism is installed on one end of mixing bucket 14, and feeding mechanism comprises the feeding inner bucket 13 of mixing bucket 14 one ends, and the bottom of feeding inner bucket 13 is provided with fixed outer bucket 12, and feeding inner bucket 13 and The connection position of the fixed outer bucket 12 is provided with a second rotating clamp shaft 16, the outer surface of the feeding inner bucket 13 is provided with a vibrating motor 15, and the bottom of the vibrating motor 15 is provided with a motor base 17, and the feeding inner bucket 13 is connected to the fixed outer bucket. Vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com