A fully automatic foaming machine

A foaming machine, fully automatic technology, applied in the field of foaming machines, can solve problems such as mixing ratio adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

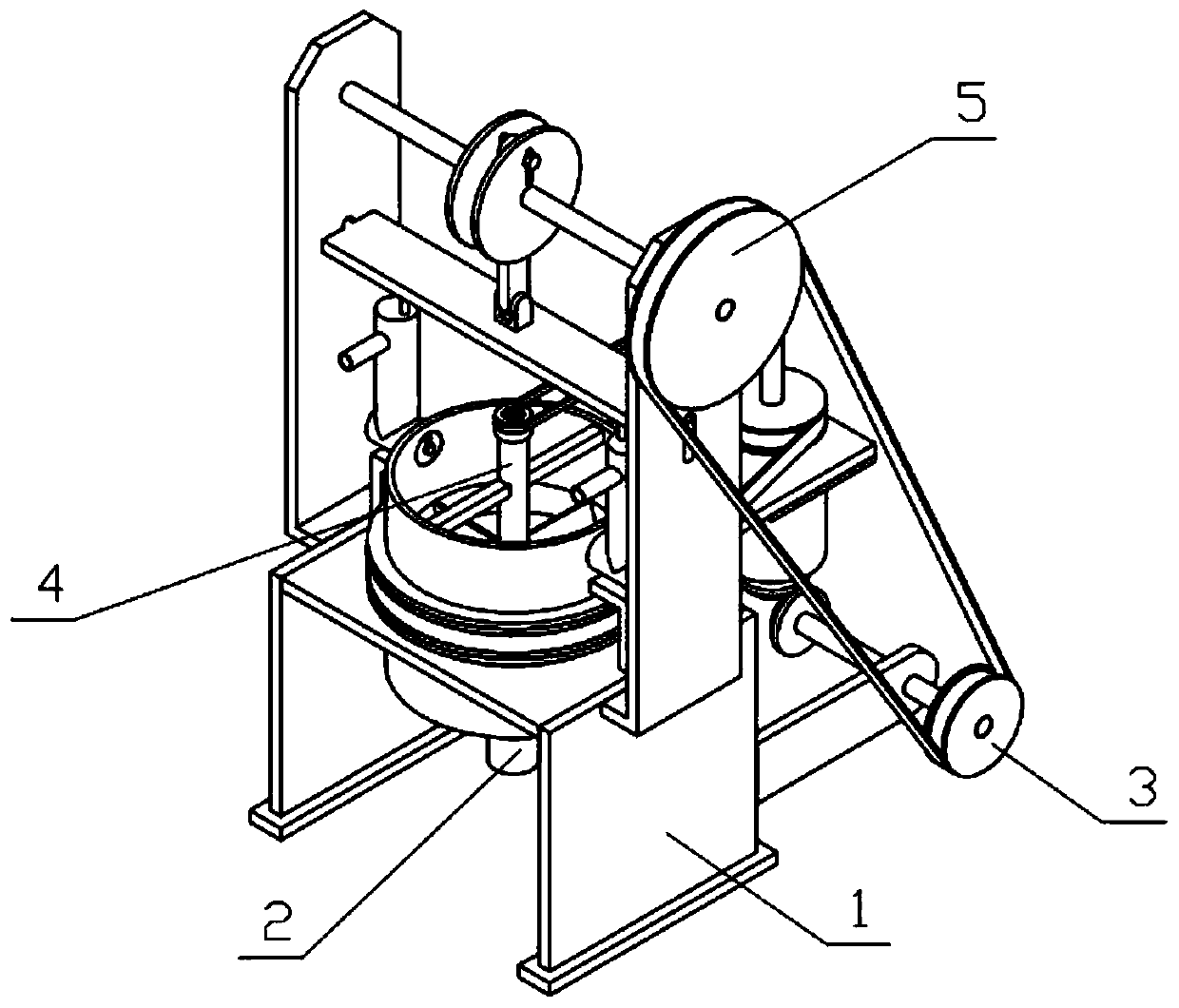

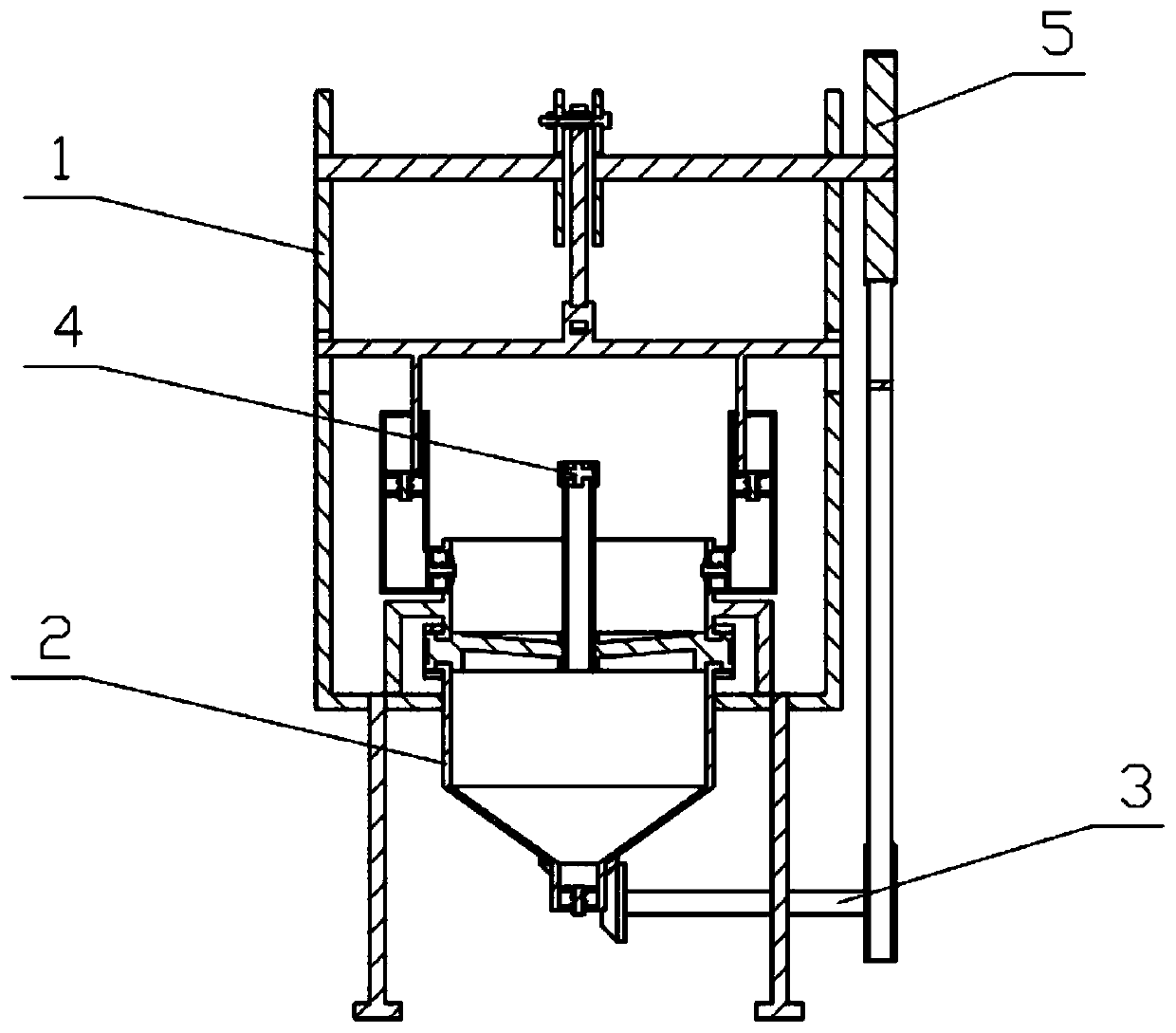

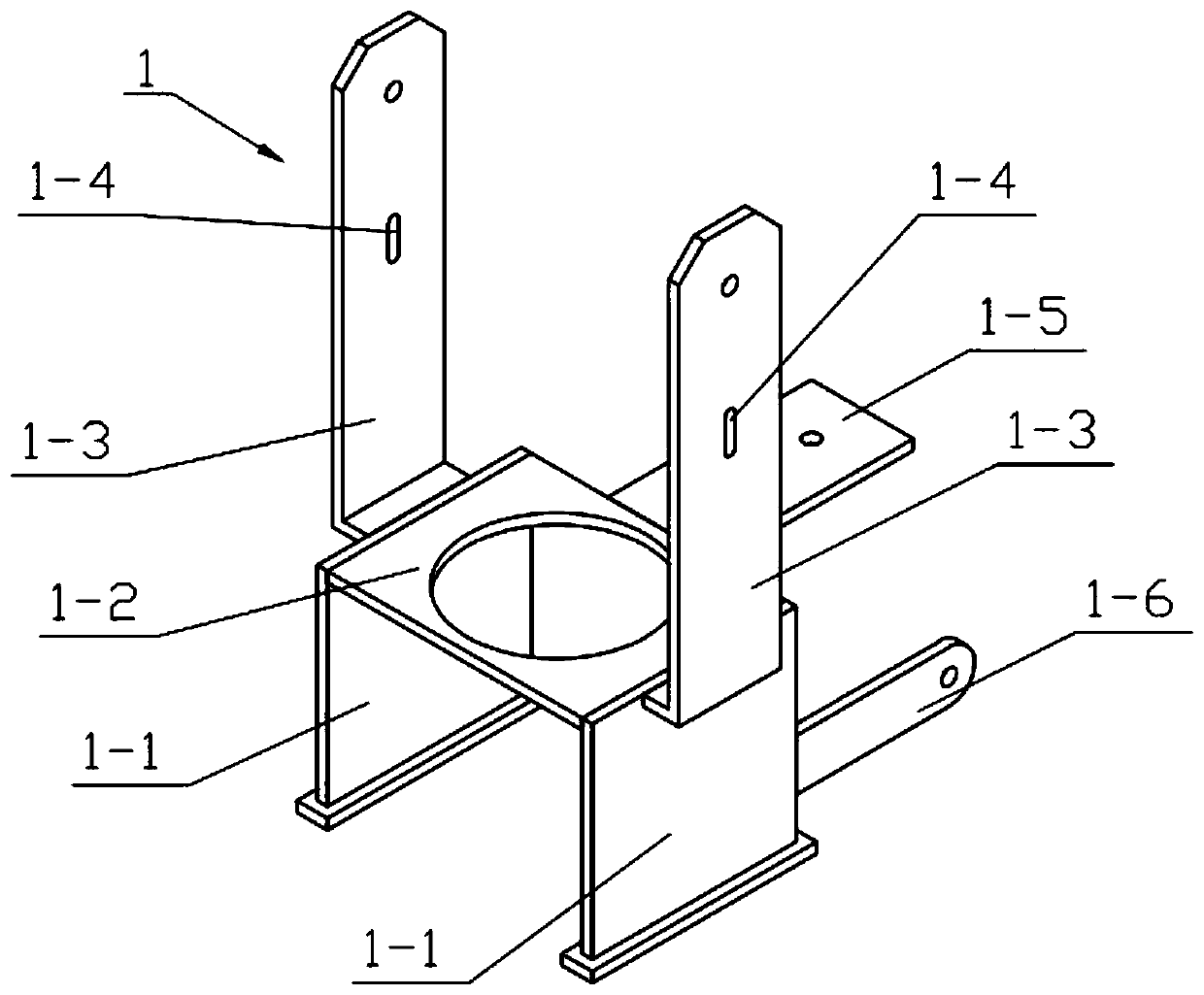

[0036] Combine below Figure 1-15 Describe this embodiment, a fully automatic foaming machine, including a complete machine support 1, a stirring support 2, a power mechanism 3, an air intake mechanism 4, and a pushing mechanism 5, which can pass through the power pulley II 3-3 and the intake pulley 4 -3 have the same diameter, and the diameter of the push pulley 5-3 is greater than the diameter of the drive pulley 3-7 so that the transmission ratio of the power mechanism 3 changes, so that the rotational speed of the motor 3-1 output is suitable for the intake mechanism 4 and the push mechanism 5, the air intake mechanism 4 squeezes the air into the stirring support 2 when it is working, and the pushing mechanism 5 squeezes the foaming agent into the stirring support 2, and the foaming agent is mixed with air and water in the mixing drum I2-1 Stirred under the action of the stirring wheel 2-4, by adjusting the sliding position of the screw 5-7 on the sliding hole 5-4, the pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com