A method for predicting prestress loss after cracking of concrete reinforcement

A concrete and prestressed technology, applied in the direction of measuring devices, special data processing applications, instruments, etc., to achieve reliable calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The invention discloses a method for predicting the prestress loss of concrete after cracking along the reinforcement, including the following steps:

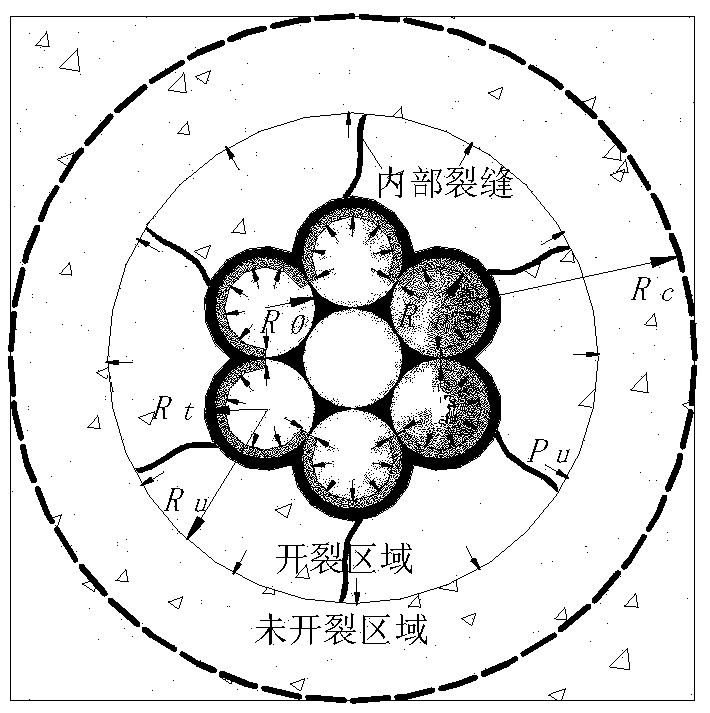

[0060] (1) Predict rust swelling and cracking of concrete: According to the basic size of the component, determine the value of the geometric parameters, and use the thick-walled thin tube theory to simulate the rust swelling and cracking of concrete. The binding force of cracked concrete predicts the rust swelling force;

[0061] (2) Analysis of the degradation of the bond strength of the corroded steel strand: establish the expressions of the adhesive force, binding force and rust expansion force between the steel strand and the concrete interface, analyze the influence of the corrosion of the steel strand on the above factors, and then calculate the corrosion of the steel strand strand bond strength;

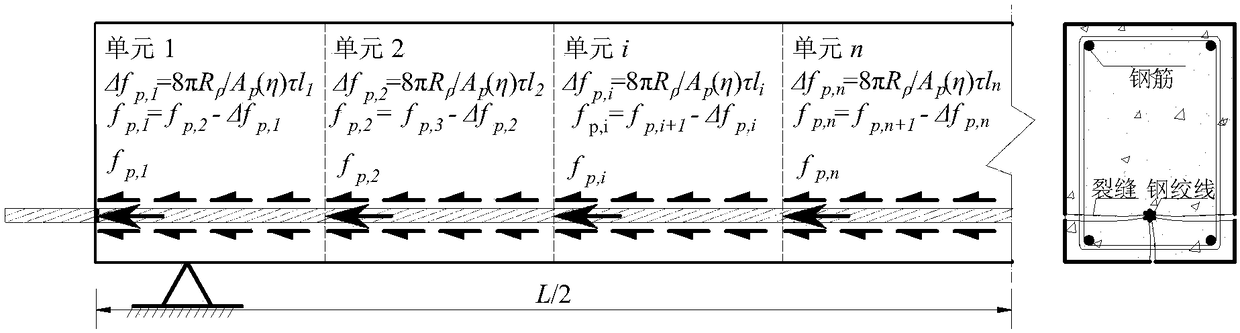

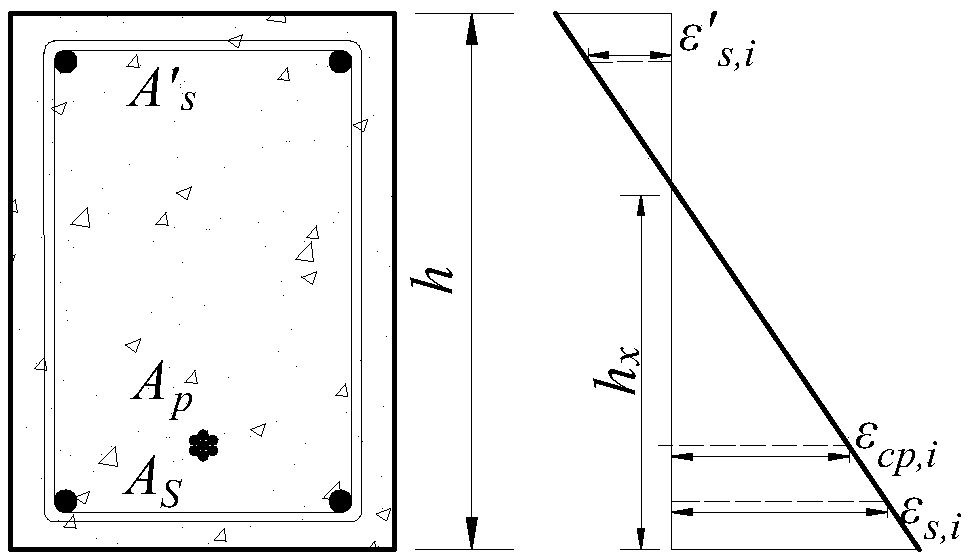

[0062] (3) Evaluate the loss of prestress caused by corrosion: discretize the pre-tensioned concrete member into mul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com