Novel deep ploughing machine capable of performing automatic sowing and using method thereof

A deep tiller, a new type of technology, applied in applications, agricultural machinery and implements, devices for capturing or killing insects, etc. The effect of simplifying the inter-farm labor process, avoiding uneven ploughing, and using good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

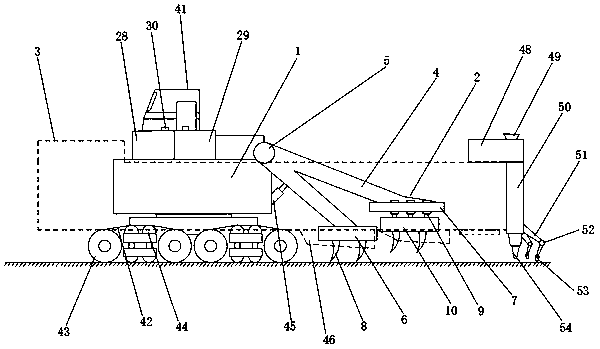

[0039] As shown in the accompanying drawings of the description, a new type of deep tiller capable of automatic sowing includes a car body 1, a plow tool 2, a soil collection and feeding device 3 and a control system; the top of the car body 1 is provided with an operating room 41 , the bottom is provided with four groups of crawler moving mechanisms 42; the plow tool 2 mainly includes a connecting fork frame 4, a front plow share 6, a connecting plate 7 and a rear plow share 10; one end of the connecting fork frame 4 is hinged on the car body 1 The rear part of the hinge is provided with a rotating motor 5, and the other end is divided into two forks, which are respectively connected to the front plow share 6 and the connecting plate 7; three groups of hydraulic cylinders 9 are arranged on the connecting plate 7; the hydraulic cylinders The end of 9 is connected to the rear plow share 10; the bottoms of the front plow share 6 and the rear plow share 10 are all arranged front a...

Embodiment 2

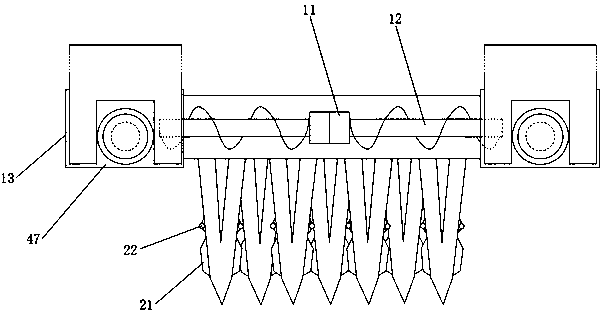

[0050] Embodiment 2 is basically the same in structure and principle as Embodiment 1, except that a filling baffle 21 is provided on the side where the front end of the coulter 8 is narrowed. The function of the filling baffle plate 21 is to supplement the gap between the coulters 8, so that the cultivated land is plowed more evenly.

Embodiment 3

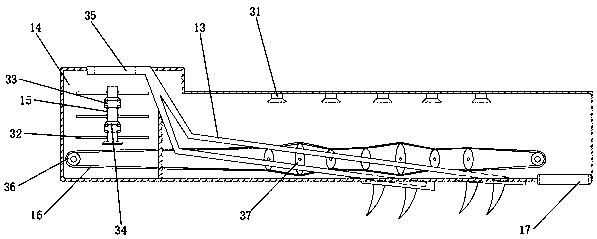

[0052] Embodiment 3 is basically the same in structure and principle as Embodiment 1, except that an inclined block 34 is provided on the top of the fertilizer spraying port 33 . The function of the soil retaining inclined block 34 is to block the fallen soil and protect the fertilizer spraying port 33 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com