Deep cultivator and method of use thereof

A technology for deep tillage machines and conveying motors, applied in the field of deep tillage machines, can solve the problems of inability to turn the soil, shallow fertilization depth, and lack of pesticide and insecticidal functions, and achieve the effect of avoiding uneven plowing and deepening the plowing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

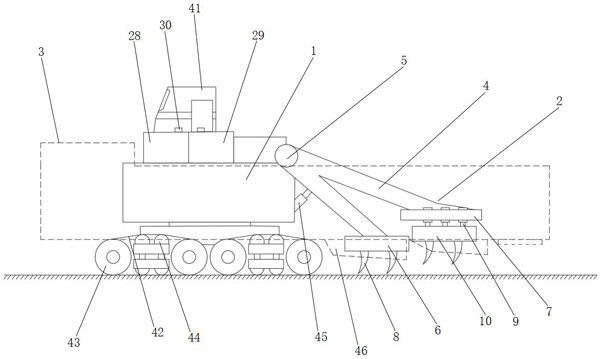

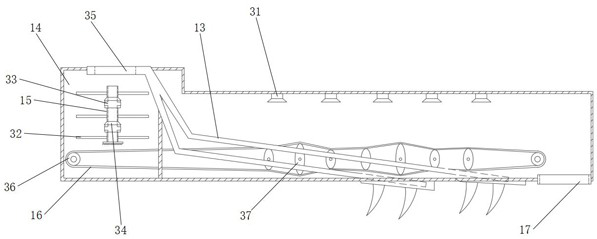

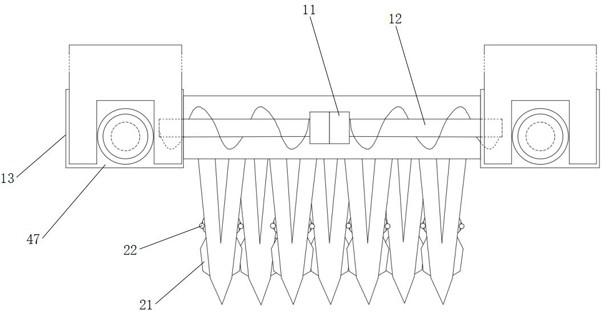

[0036] As shown in the drawings of the description, a deep tiller includes a car body 1, and also includes a plow 2, a soil collection and feeding device 3 and a control system; the top of the car body 1 is provided with an operating room 41, and the bottom is provided with four A crawler moving mechanism 42; the plow tool 2 mainly includes a connecting fork frame 4, a front plow share 6, a connecting plate 7 and a rear plow share 10; one end of the connecting fork frame 4 is hinged at the tail of the car body 1, and A rotating motor 5 is provided, and two forks are separated from the other end, and are respectively connected to the front plow share 6 and the connecting plate 7; three sets of hydraulic cylinders 9 are arranged on the connecting plate 7; the ends of the hydraulic cylinders 9 are connected to Rear plow share 10; The bottoms of the front plow share 6 and the rear plow share 10 are arranged front and rear with two rows of head-down coulters 8; A group of conveying...

Embodiment 2

[0046] Embodiment 2 is basically the same in structure and principle as Embodiment 1, except that a filling baffle 21 is provided on the side where the front end of the coulter 8 is narrowed. The function of the filling baffle plate 21 is to supplement the gap between the coulters 8, so that the cultivated land is plowed more evenly.

Embodiment 3

[0048] Embodiment 3 is basically the same in structure and principle as Embodiment 1, except that an inclined block 34 for retaining soil is provided on the top of the fertilizer spraying port 33 . The function of the soil retaining inclined block 34 is to block the fallen soil and protect the fertilizer spraying port 33 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com