Linear pebble laying device for garden

A cobblestone and straight line technology is applied in the field of linear cobblestone laying devices for gardens, which can solve the problems of easy fatigue of laying personnel, heavy workload and poor laying effect, and achieve the effect of good laying effect and preventing blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

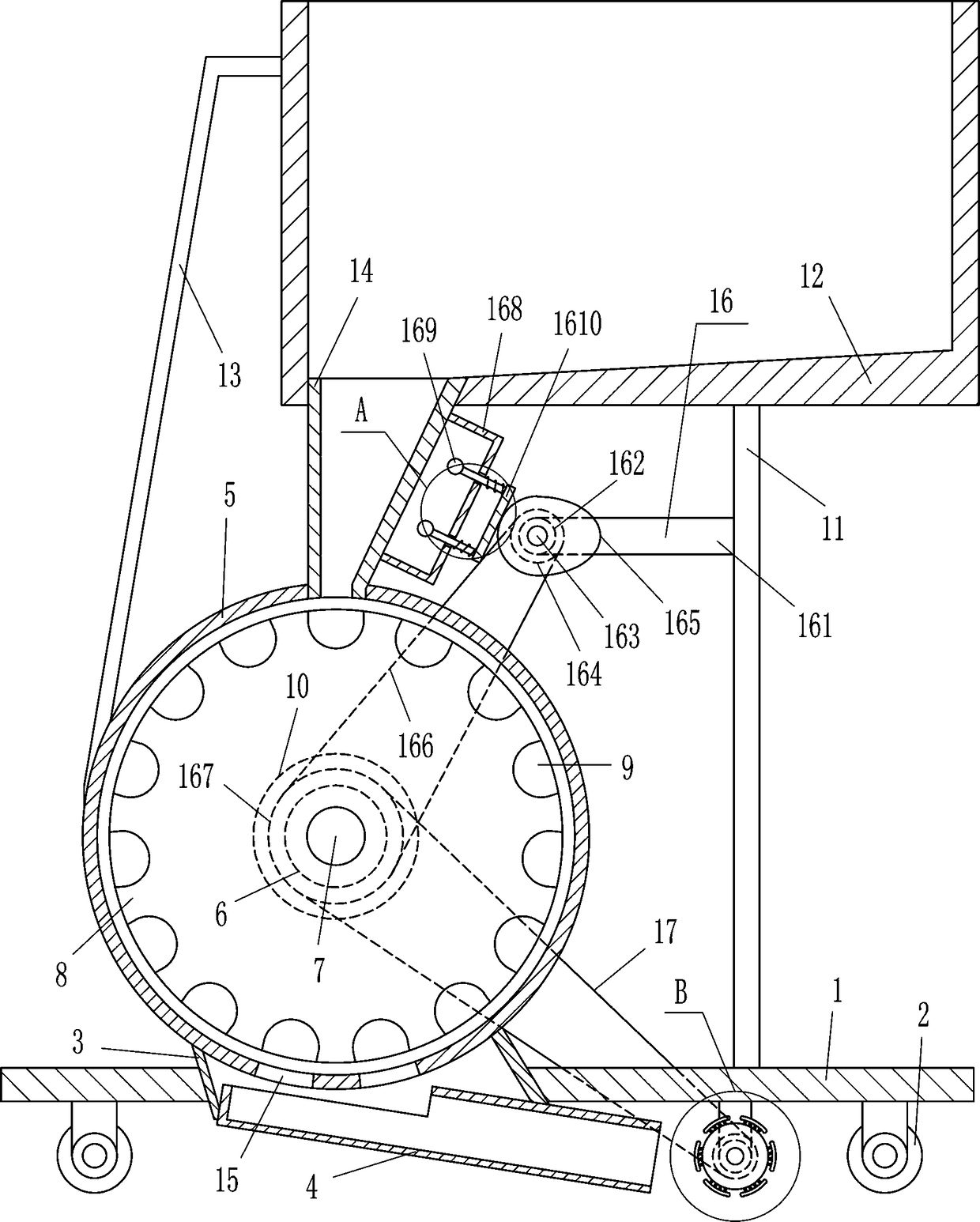

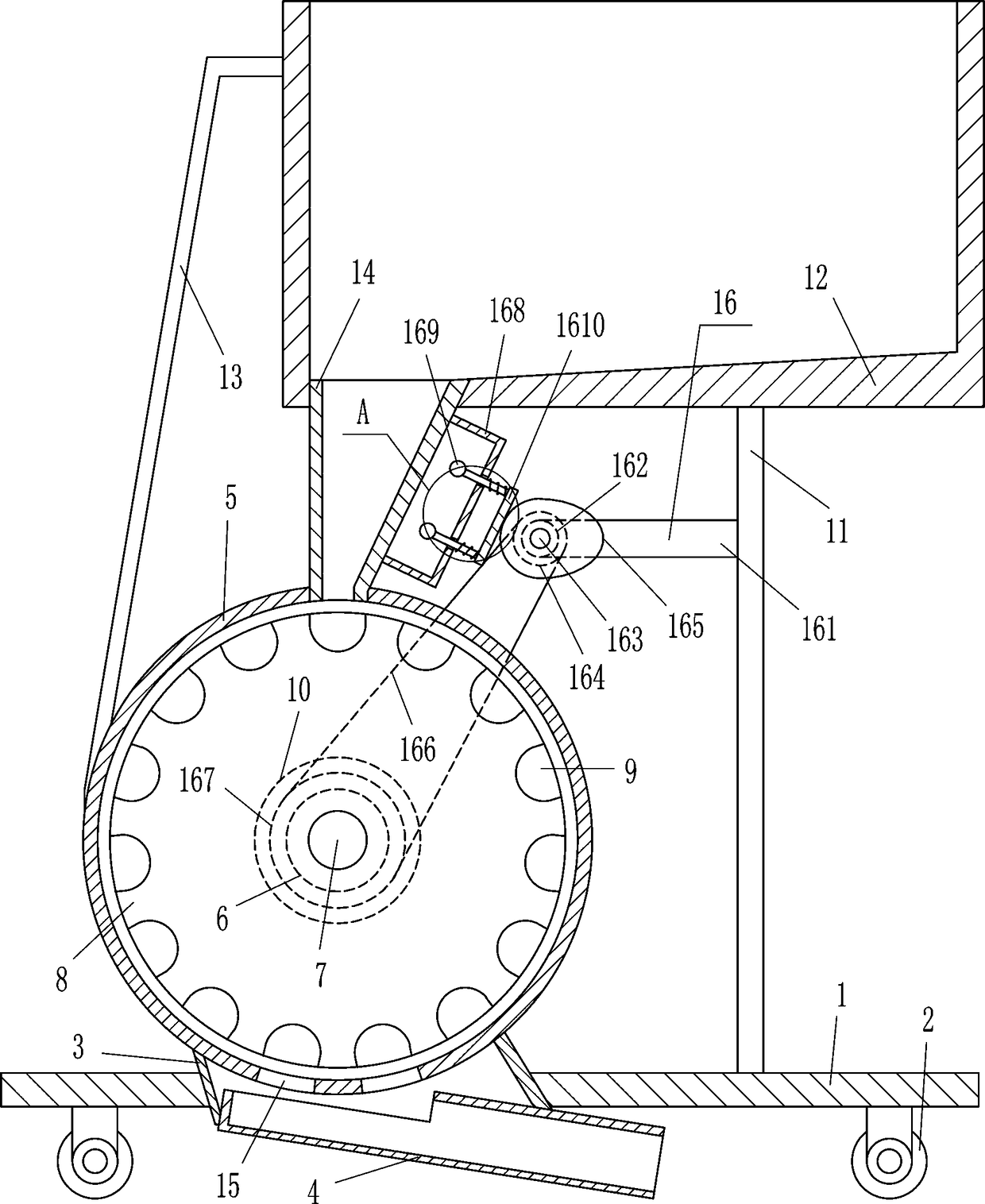

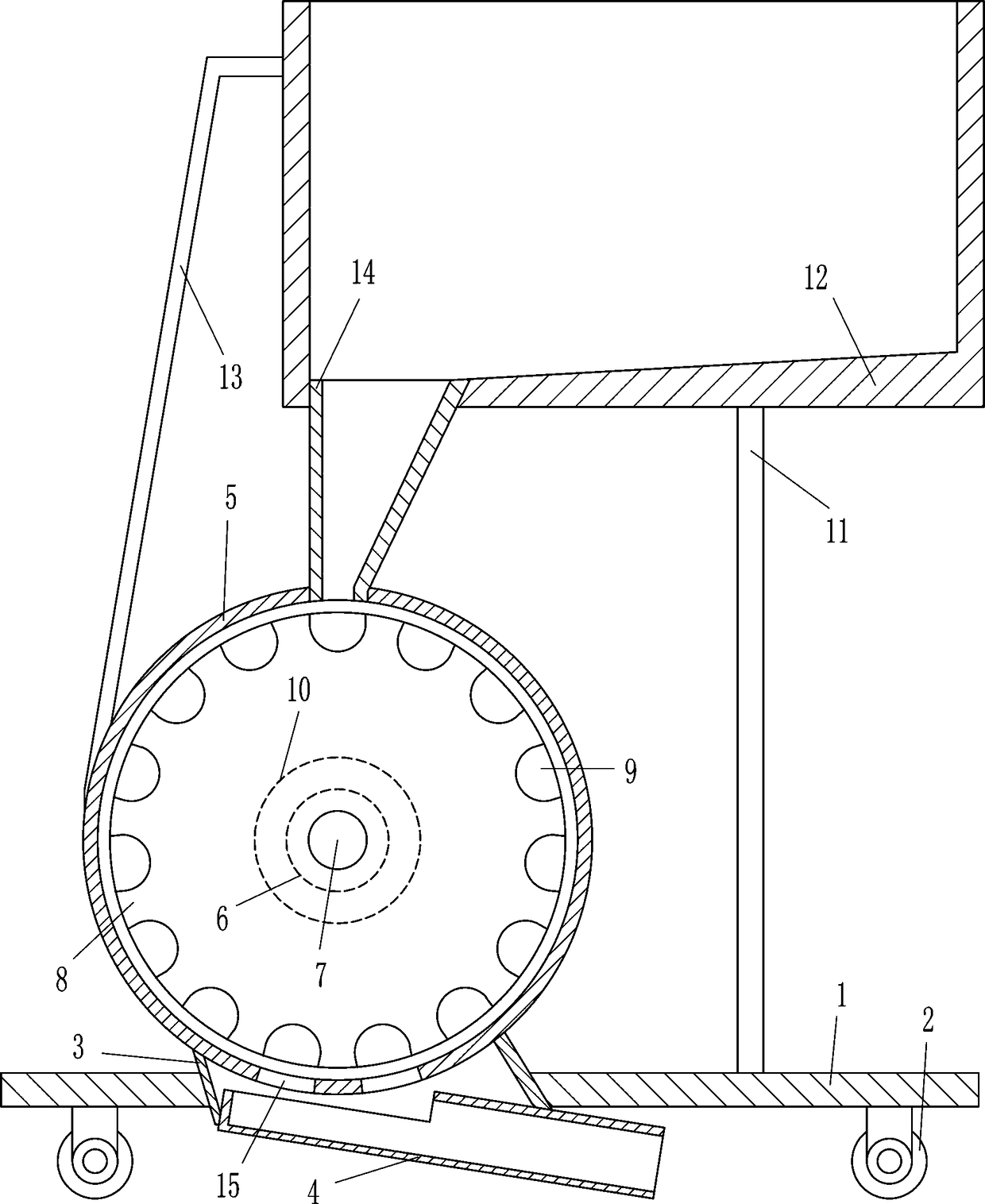

[0019] A device for laying cobblestones in a straight line for gardening, such as Figure 1-5 As shown, it includes bottom plate 1, wheel 2, hollow cylinder 3, discharge frame 4, cylinder body 5, first bearing seat 6, first rotating shaft 7, first turntable 8, motor 10, support rod 11, placement frame 12 , connecting rod 13 and lower hopper 14, wheels 2 are installed symmetrically on the left and right sides of the bottom of the bottom plate 1, a hollow cylinder 3 is installed on the left side of the bottom plate 1, and a discharge frame 4 is installed on the bottom of the hollow cylinder 3, and the discharge frame 4 and the hollow The cylinder 3 is connected inside, and the top of the hollow cylinder 3 is equipped with a cylinder body 5. The first bearing seat 6 is embedded in the center of the cylinder body 5 at the front and rear sides, and the first rotating shaft 7 is connected between the first bearing seats 6 at the front and rear sides. , the middle part of the first r...

Embodiment 2

[0021] A device for laying cobblestones in a straight line for gardening, such as Figure 1-5 As shown, it includes bottom plate 1, wheel 2, hollow cylinder 3, discharge frame 4, cylinder body 5, first bearing seat 6, first rotating shaft 7, first turntable 8, motor 10, support rod 11, placement frame 12 , connecting rod 13 and lower hopper 14, wheels 2 are installed symmetrically on the left and right sides of the bottom of the bottom plate 1, a hollow cylinder 3 is installed on the left side of the bottom plate 1, and a discharge frame 4 is installed on the bottom of the hollow cylinder 3, and the discharge frame 4 and the hollow The cylinder 3 is connected inside, and the top of the hollow cylinder 3 is equipped with a cylinder body 5. The first bearing seat 6 is embedded in the center of the cylinder body 5 at the front and rear sides, and the first rotating shaft 7 is connected between the first bearing seats 6 at the front and rear sides. , the middle part of the first r...

Embodiment 3

[0024] A device for laying cobblestones in a straight line for gardening, such as Figure 1-5 As shown, it includes bottom plate 1, wheel 2, hollow cylinder 3, discharge frame 4, cylinder body 5, first bearing seat 6, first rotating shaft 7, first turntable 8, motor 10, support rod 11, placement frame 12 , connecting rod 13 and lower hopper 14, wheels 2 are installed symmetrically on the left and right sides of the bottom of the bottom plate 1, a hollow cylinder 3 is installed on the left side of the bottom plate 1, and a discharge frame 4 is installed on the bottom of the hollow cylinder 3, and the discharge frame 4 and the hollow The cylinder 3 is connected inside, and the top of the hollow cylinder 3 is equipped with a cylinder body 5. The first bearing seat 6 is embedded in the center of the cylinder body 5 at the front and rear sides, and the first rotating shaft 7 is connected between the first bearing seats 6 at the front and rear sides. , the middle part of the first r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com