Combined firework emitter cold pressing combined die

A technology of combining fireworks and combining molds, which is used in fireworks, offensive equipment, weapon types, etc., can solve the problems of rough surface of the cylinder, easy pulling of the wall of the cylinder cavity, low production efficiency, etc., to ensure quality, reduce production costs, and assembly. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

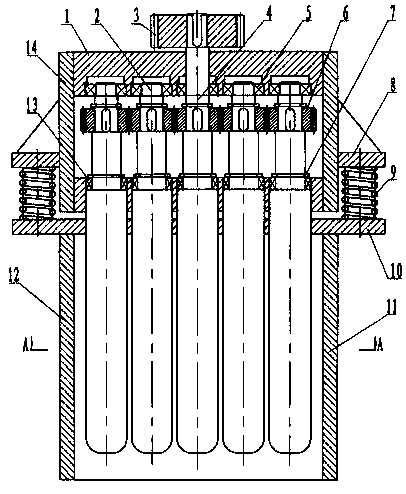

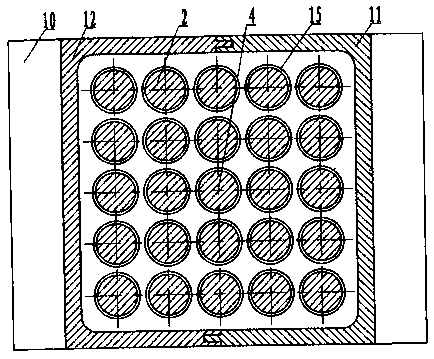

[0020] Below, the present invention will be described in more detail with reference to the accompanying drawings and preferred embodiments.

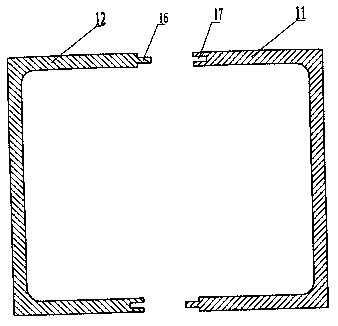

[0021] Combined firework launcher cold-press combined mold of the present invention, as figure 1 , figure 2 , image 3 As shown, it has a structure consisting of a cover plate 1, a passive shaft 2, a transmission device 3, a driving shaft 4, an upper bearing 5, a rotating device 6, a retaining spring 7, a spring seat 8, a spring 9, and a demoulding plate 10. The right outer mold 11, the left outer mold 12, the lower bearing 13, the casing 14, the projection 16, the groove 17 and the fasteners are assembled to form a combination mould.

[0022] The structural features are: the cover plate 1 is fixedly connected to the box body 14, and the several passive shafts 2 and one active shaft 4 are penetrated in the inner cavity of the box body 14 and formed by the right outer mold 11 and the left outer mold 12. In the cavity, the upper parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com