Sedimentation tank desilting device

A technology of dredging device and sedimentation tank, which is applied in the direction of sedimentation separation, feeding/discharging device of sedimentation tank, chemical instruments and methods, etc. It can solve the problems of many turnover sedimentation tanks, unsolved dredging problems, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

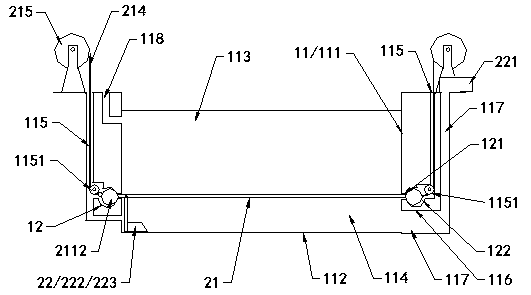

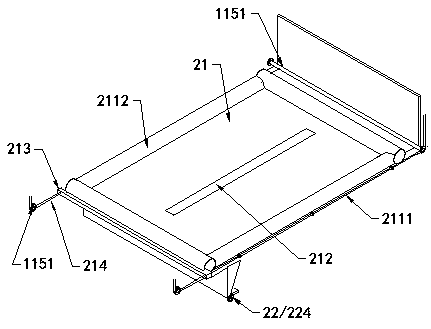

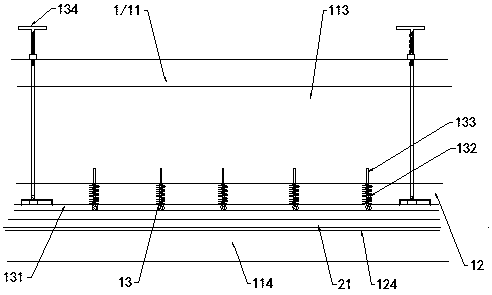

[0025] The present invention includes a sedimentation tank 1 and a silt discharge mechanism 2 .

[0026] Such as figure 1 As shown, the sedimentation tank 1 is rectangular, the bottom 112 of the pool body 11 is surrounded by a vertical wall 111, and the upper end of the pool body is provided with a sewage inlet pipe 118, which is used to introduce sewage to be treated. After the sewage is treated, it settles in the pool. Divided into a water purification layer 113 and a sedimentation layer 114, the vertical wall between the water purification layer and the sedimentation layer is provided with a horizontal groove sandwiching channel 12, the grooves in the front end and the vertical walls on both sides are connected at an angle, and the rear The lower end of the side vertical wall is provided with a partition 116, and the upper surface of the partition is flush with the lower plate 124 of the grooves on both sides. Annular groove clamping channel.

[0027] The upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com