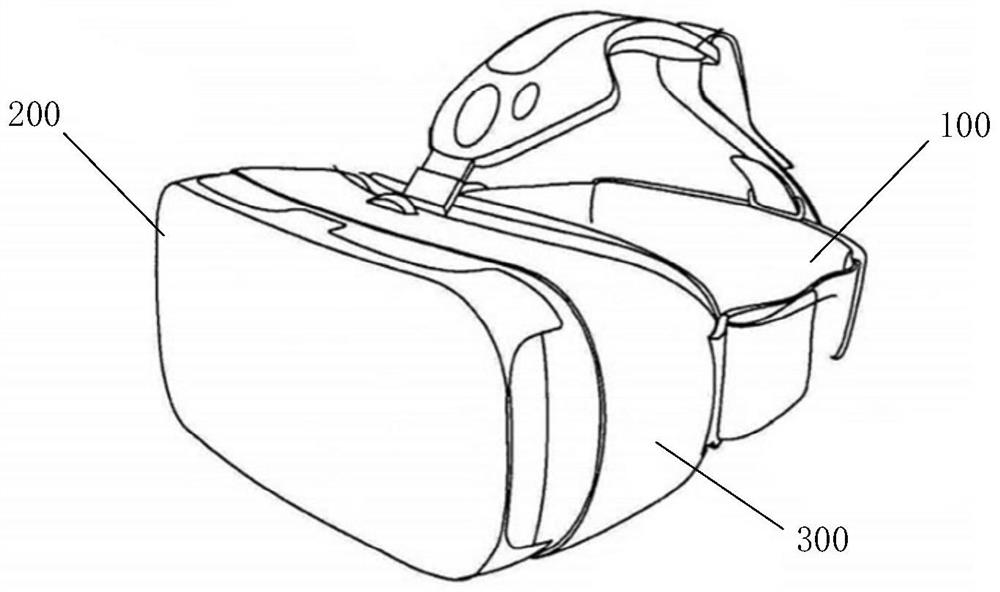

A composite shading cloth and a shading component of a virtual reality device

A technology of virtual reality and shading cloth, applied in the field of optics, can solve the problems of increased weight of virtual reality equipment and poor shading effect of the hood 300, and achieve good shading effect, improved comfort, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

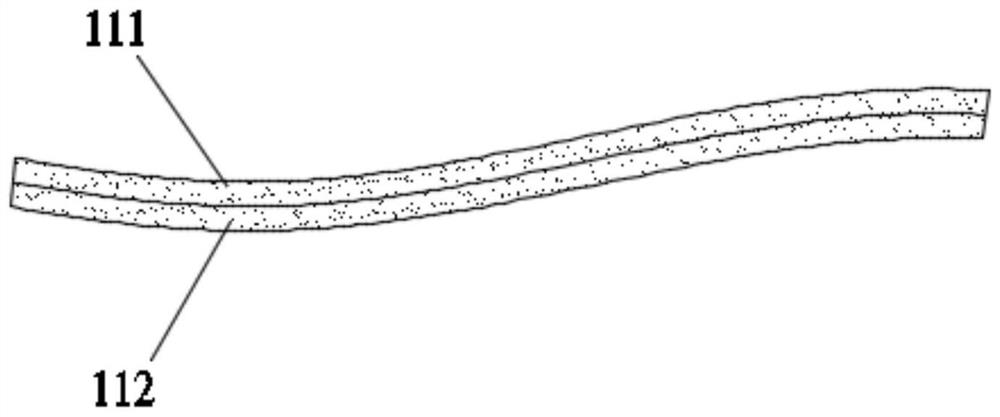

[0036] figure 2 It is a schematic structural diagram of a composite shading cloth provided in Example 1 of the present application.

[0037] The embodiment of the present application provides a composite shading cloth, such as figure 2 As shown, it includes a first knitted layer 111 and a second knitted layer 112;

[0038]Wherein, the first knitted layer 111 is made of 3% spandex and 97% milk silk, and the thickness of the first knitted layer 111 is 0.25mm; the second knitted layer 112 is made of 3% spandex and 97% Made of milk silk, the thickness of the first knitted layer 111 is 0.25mm; the first knitted layer 111 and the second knitted layer 112 are glued together by water-based glue, and the texture of the first knitted layer 111 It forms a certain angle with the texture of the second knitted layer 112 .

[0039] Spandex is a polyurethane fiber with strong elasticity. It can stretch up to 600% and can return to its original shape. It is stronger, more breathable and m...

Embodiment 2

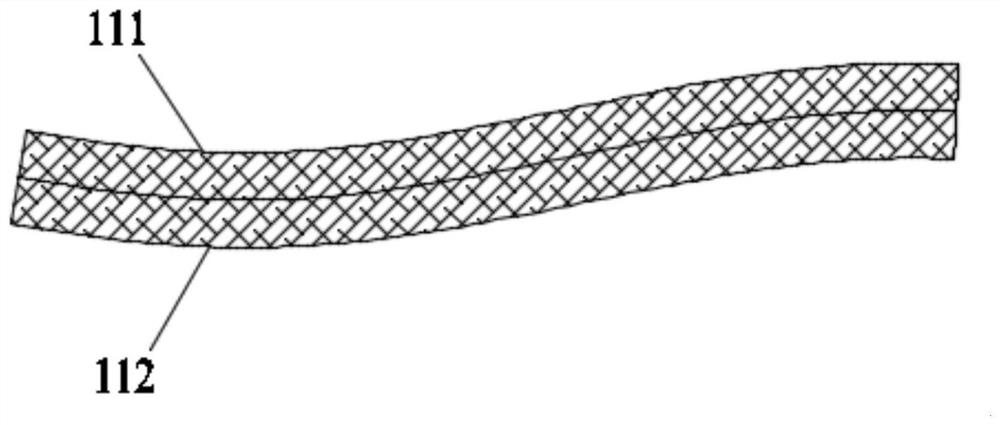

[0042] image 3 It is a schematic structural diagram of a composite shading cloth provided in Example 2 of the present application.

[0043] The embodiment of the present application provides a composite shading cloth, such as image 3 As shown, it includes a first knitted layer 111 and a second knitted layer 112;

[0044] Wherein, the first knitted layer 111 is made of 3% spandex and 97% rayon, the thickness of the first knitted layer 111 is 0.6mm; the second knitted layer 112 is made of 3% spandex and 97% Made of rayon, the thickness of the first knitted layer 111 is 0.6mm; the first knitted layer 111 and the second knitted layer 112 are glued together by water-based glue, and the texture of the first knitted layer 111 It forms a certain angle with the texture of the second knitted layer 112 .

[0045] In the second embodiment of the present application, different from the first embodiment, the thicknesses of the first knitted layer 111 and the second knitted layer 112 ar...

Embodiment 3

[0047] Figure 4 It is a schematic structural diagram of a composite shading cloth provided in Embodiment 3 of the present application.

[0048] The embodiment of the present application provides a composite shading cloth, such as Figure 4 As shown, it includes a first knitted layer 111 and a second knitted layer 112;

[0049] Wherein, the first knitted layer 111 is made of 15% spandex and 85% milk silk, and the thickness of the first knitted layer 111 is 0.25mm; the second knitted layer 112 is made of 15% spandex and 85% Made of milk silk, the thickness of the second knitted layer 112 is 0.6mm; the first knitted layer 111 and the second knitted layer 112 are glued together by water-based glue, and the texture of the first knitted layer 111 It forms a certain angle with the texture of the second knitted layer 112 .

[0050] In the third embodiment of the present application, the first knitted layer 111 and the second knitted layer 112 are both composed of 15% spandex and 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com