Drilling device for abrasion-resisting building material machining

A technology for building materials and drilling devices, applied in boring/drilling, metal processing equipment, drilling/drilling equipment, etc., can solve problems such as waste of manpower, poor shock absorption effect, and inability to adjust height, and achieve improved The degree of automation, the effect of prolonging the service life and reducing the vibration phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

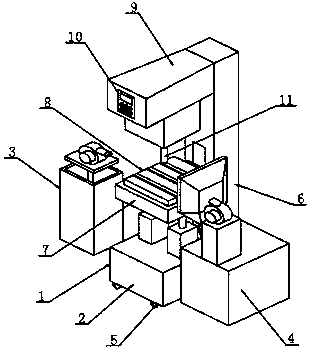

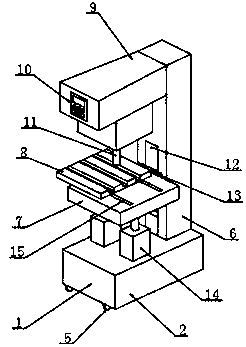

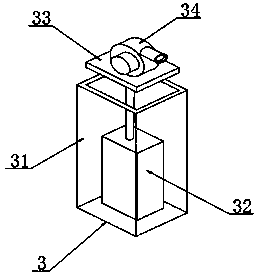

[0025] see Figure 1~5 , in an embodiment of the present invention, a drilling device for processing wear-resistant building materials includes a drilling machine body 1, a fixing seat 2 is installed on the bottom of the drilling machine body 1, and one side of the drilling machine body 1 is set There is a blowing device 3, the other side is provided with a dust collecting device 4, the lower surface of the fixed seat 2 is fixedly equipped with a shock absorbing wheel 5, and the upper surface rear side of the fixed seat 2 is fixedly provided with a column 6, and the front of the column 6 The surface is vertically provided with a slide rail 12, and a workbench 7 is installed on the front side of the column 6, and a fixed plate 13 that can slide up and down is fixedly installed at the joint between the column 6 and the workbench 7, and the lower end of the workbench 7 is located at the fixed seat 2 A lifting cylinder 14 is fixedly installed at the front side of the upper surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com