Ink cartridge fluid flow device

A fluid flow device, ink cartridge technology, applied in printing and other directions, can solve problems such as difficulty in detecting the ink level of the ink chamber, lack of information transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

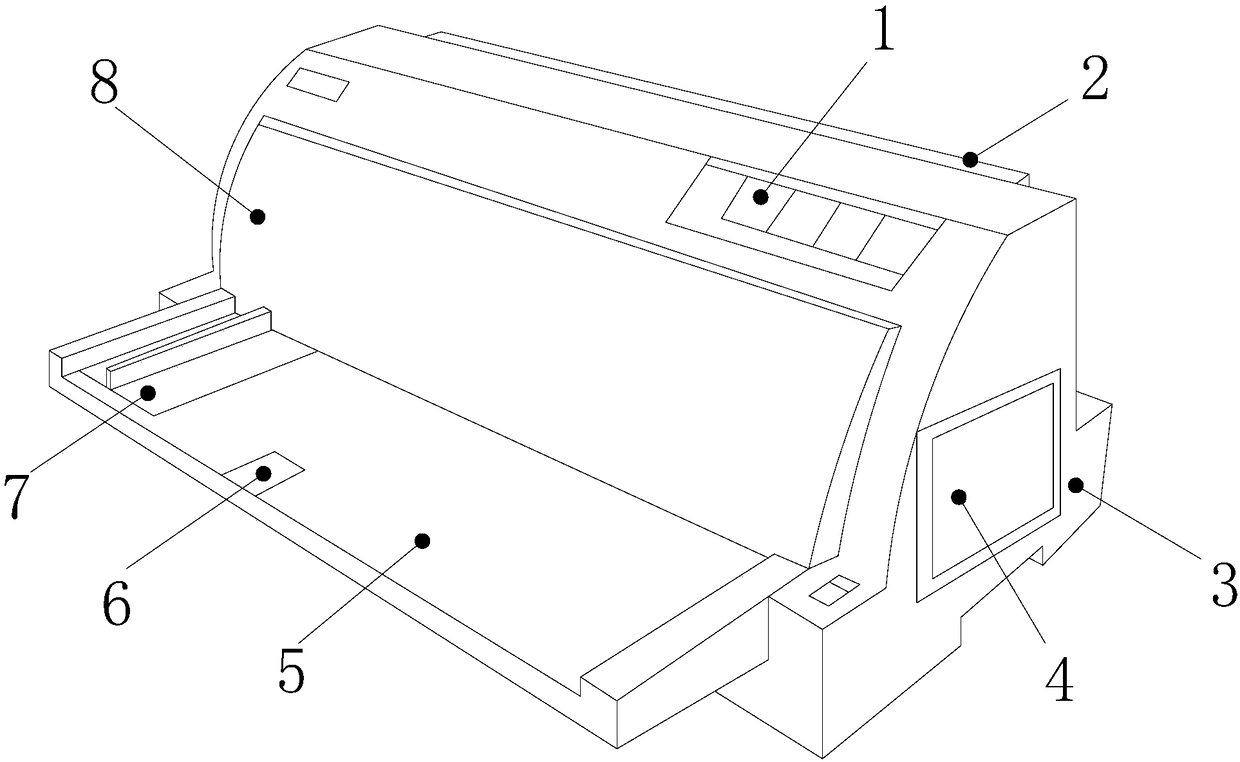

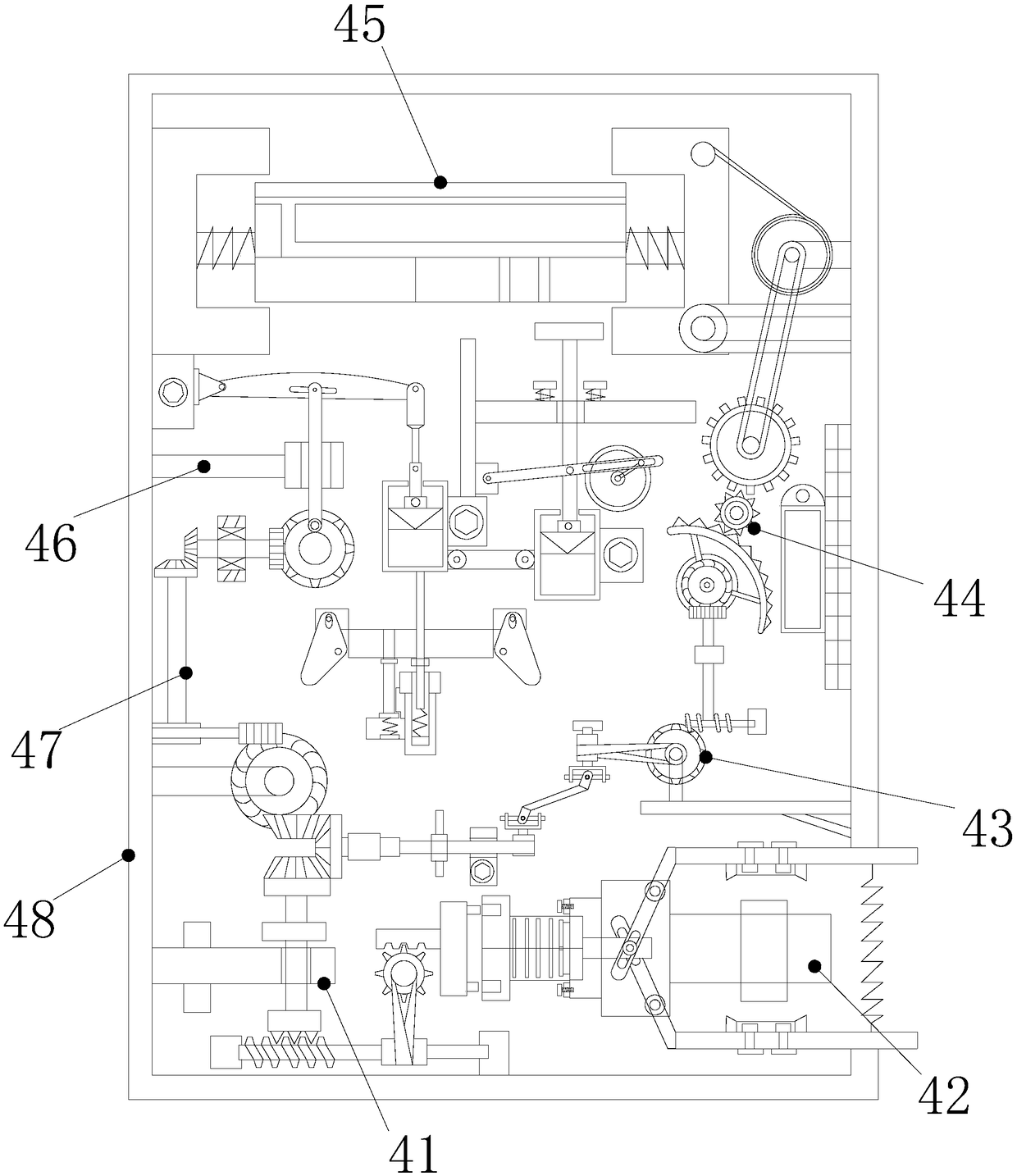

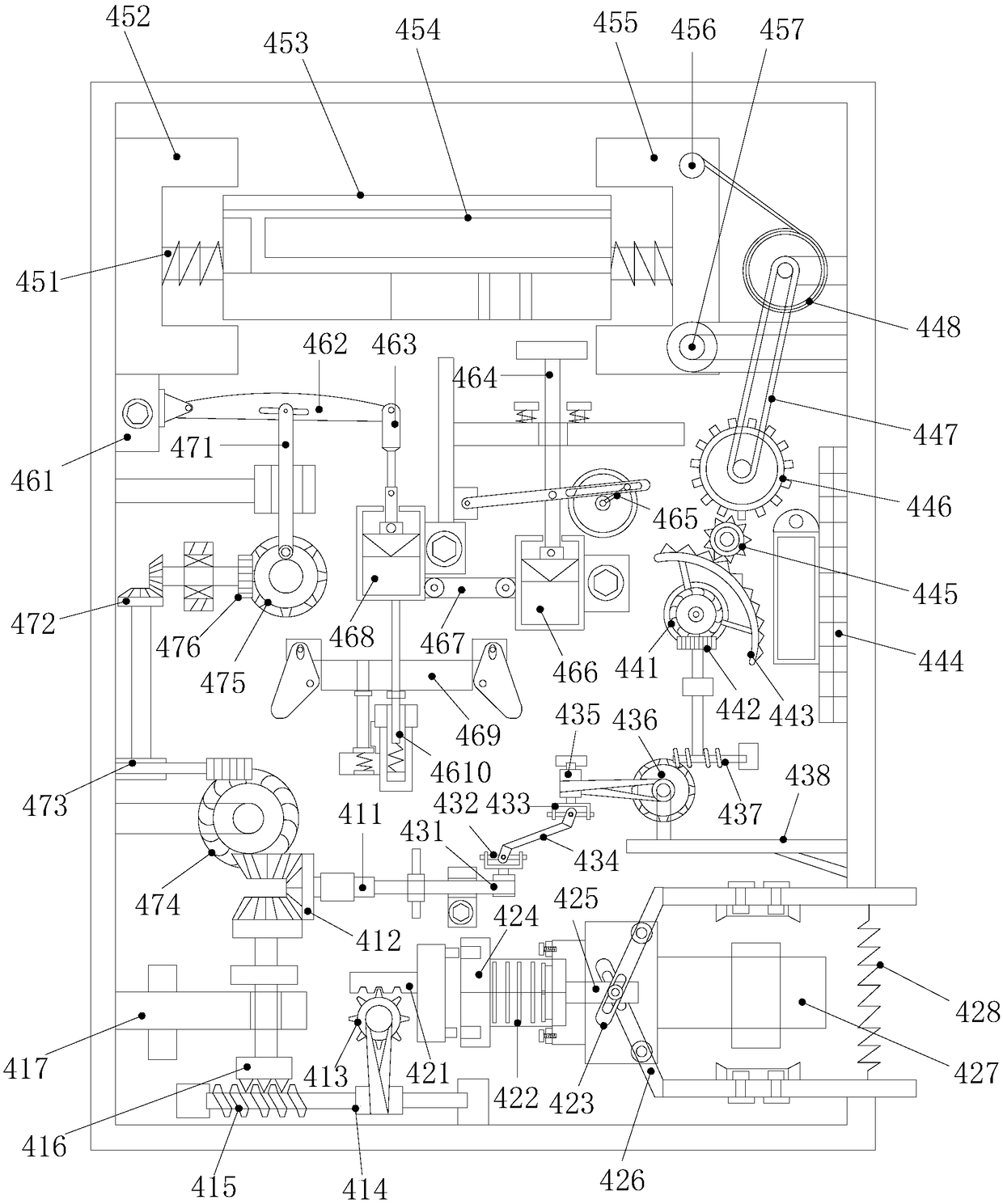

[0023] see Figure 1-Figure 4, the present invention provides an ink cartridge fluid flow device: its structure includes a mode adjustment button 1, a paper storage port 2, a printer body 3, an automatic ejection mechanism 4, a print outlet 5, a limit block 6, an isolation plate 7, and an ink cartridge cover 8 , the mode adjustment button 1 is provided with more than two and is respectively inlaid on the upper right of the surface of the printer body 3, the ink cartridge cover 8 is fixed on the center of the surface of the printer body 3 by a screw, and the limit block 6 is fixed on the surface of the printer body 3 by a screw. Above the print outlet 5, the paper storage port 2 is fixed behind the printer body 3 by rivets, the isolation plate 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com