A tool for installing and disassembling long bolts inside equipment

A long bolt assembly and disassembly technology, which is applied in the field of long bolt assembly and disassembly tools inside the equipment, can solve the problems of difficulty in the accurate installation position of bolts, affecting the efficiency of maintenance work, and inconvenient installation and disassembly of bolts, so as to ensure the reliability of work and service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

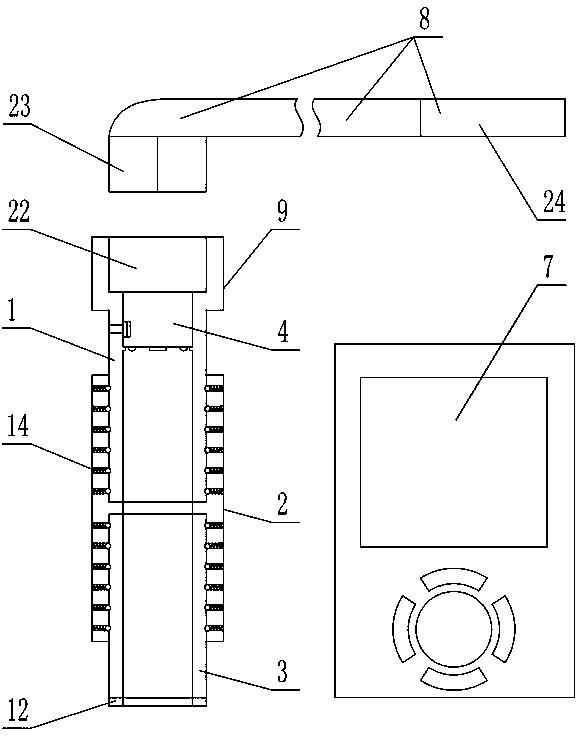

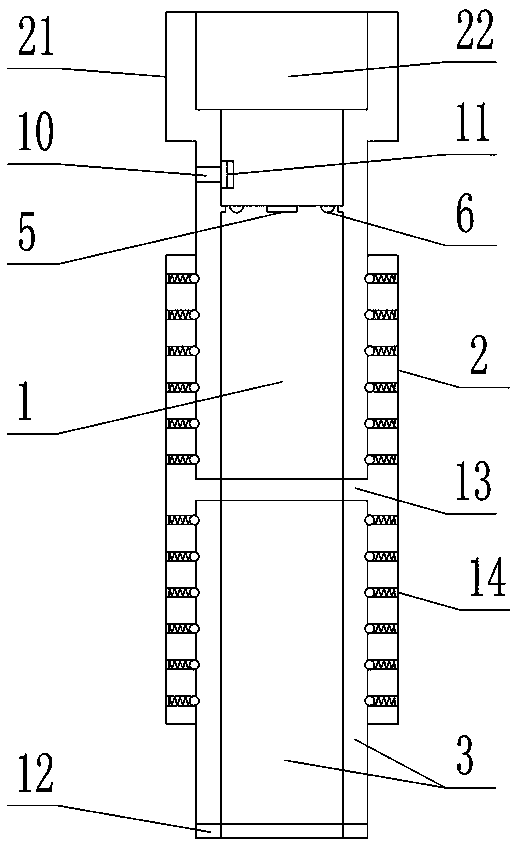

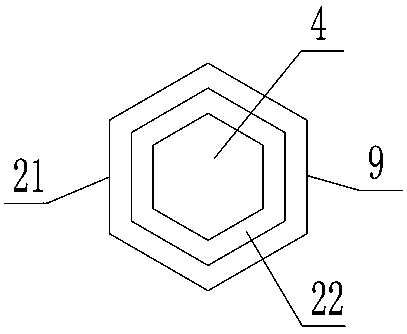

[0030] As shown in the figure, the tool for installing and disassembling long bolts inside the device includes an input sleeve 1 , a connecting sleeve 2 and an output sleeve 3 that extend in the same direction and are hollow. The inner wall of the output end of the output sleeve is a regular hexagon that fits with the nut. The input sleeve is fitted with the input section of the inner cavity of the connecting sleeve and the two can only slide in the relative axial direction. The output sleeve and the connecting sleeve The output section of the inner chamber is plug-fitted and the two can only be slid relative to each other in the axial direction. A wireless monitor 4 is installed in the inner cavity of the input end of the input sleeve, a camera 5 facing the inner cavity of the output sleeve is installed on the wireless monitor, and a supplementary light 6 facing the inner cavity of the output sleeve is also installed on the wireless monitor. . This patent also includes a wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com