Automatic assembling machine for toy car

An automatic assembly machine and toy car technology, applied in toy cars, toys, entertainment, etc., can solve the problems of cumbersome processing and achieve the effects of not easy to fall off, high degree of assembly automation, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

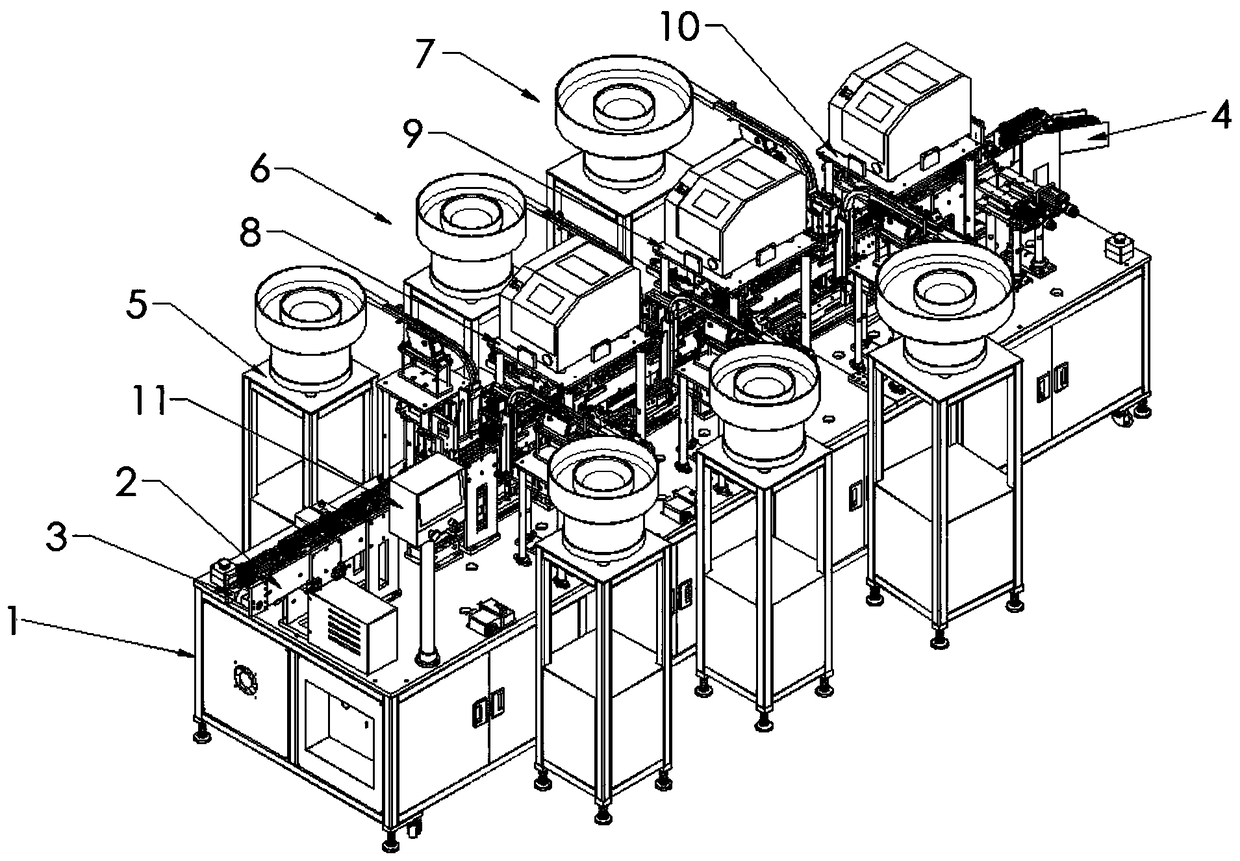

[0015] Please refer to the figure, in an embodiment of the present invention, a toy car automatic assembly machine includes a frame 1, a feeding mechanism 2 and a control touch screen 11, the feeding mechanism 2 is horizontally arranged on the frame 1, and the feeding mechanism 2 is composed of a speed regulating motor, The synchronous wheel and the synchronous belt are formed, the toy car is placed on the synchronous belt of the feeding mechanism 2, and the synchronous wheel is driven by the speed regulating motor to rotate to realize the movement of the synchronous belt, and the toy car on it is moved horizontally; the control touch screen 11 is fixedly installed On the frame 1, the equipment is controlled by controlling the start-up and shutdown of the internal structure of the assembly machine by controlling the touch screen 11; one end of the feeding mechanism 2 is set as the material inlet 3, and the other end is set as the material outlet 4, so that the toy car Enter the...

Embodiment 2

[0020] Both sides of the feeding mechanism 2 are provided with rear small tire feeding structure 5, rear small tire upper tire stud structure 8, medium and small tire feeding structure 6, medium and small tire upper tire stud structure 9, and front large tire feeding structure. The structure 7 and the tire stud structure 10 on the front big tire are arranged symmetrically on both sides corresponding to the same structure, and the two sides are assembled simultaneously.

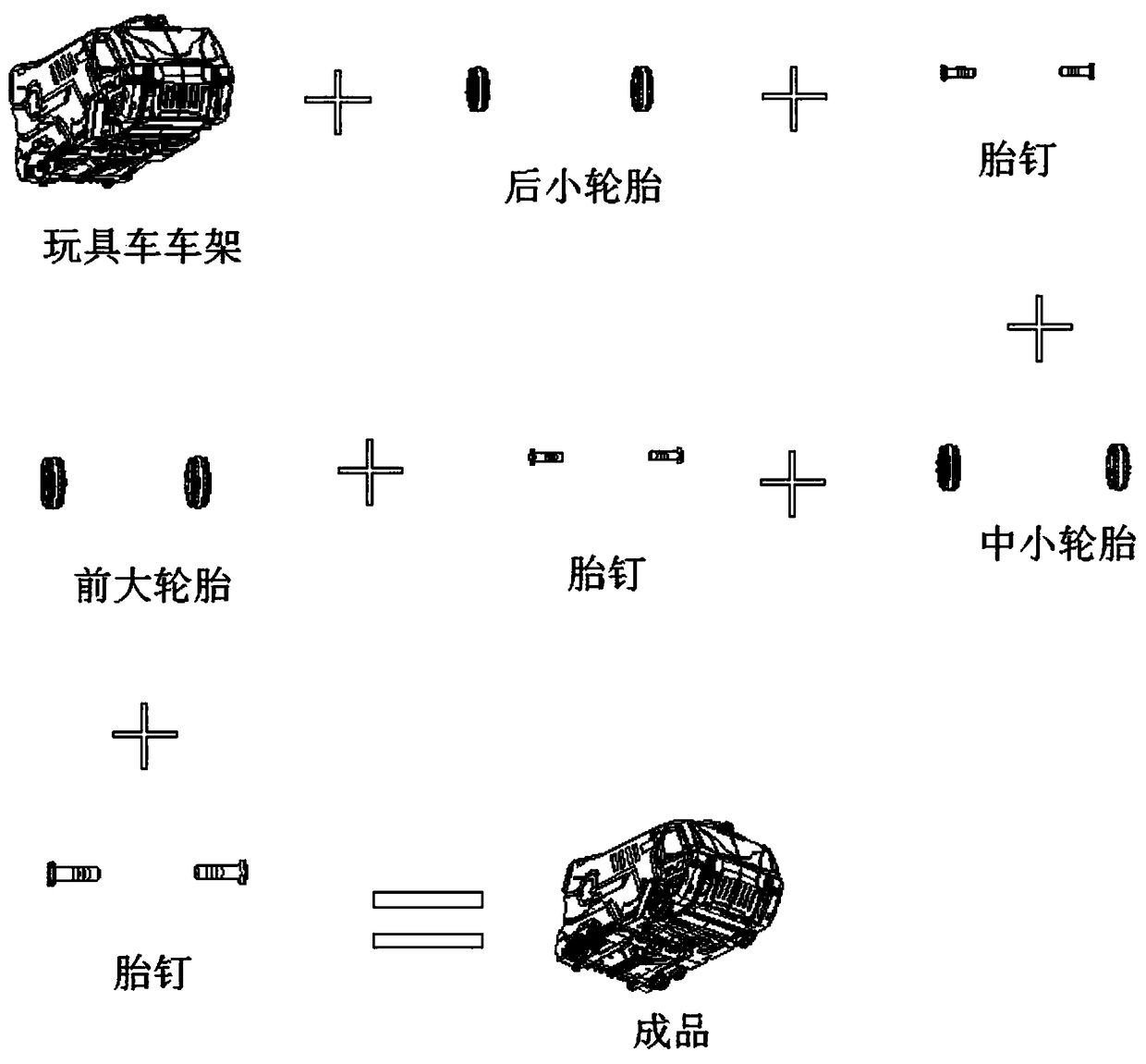

[0021] Put the toy car that needs to be assembled on the feeding mechanism 2 from the material inlet 3, and the toy car is transported on the feeding mechanism 2, and then passes through the rear small tire feeding structure 5, the rear small tire upper stud structure 8, and the middle and small tires. Material structure 6, small and medium tire upper tire stud structure 9, front large tire feeding structure 7, front large tire upper stud structure 10, realize the assembly of rear small tires, medium and small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com