Grouting or piling completeness detection device

A detection device and technology of completion degree, which is applied in the testing of infrastructure, construction, infrastructure engineering, etc., and can solve the problems of low quality, inaccurate measurement results, and limited space for piling holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

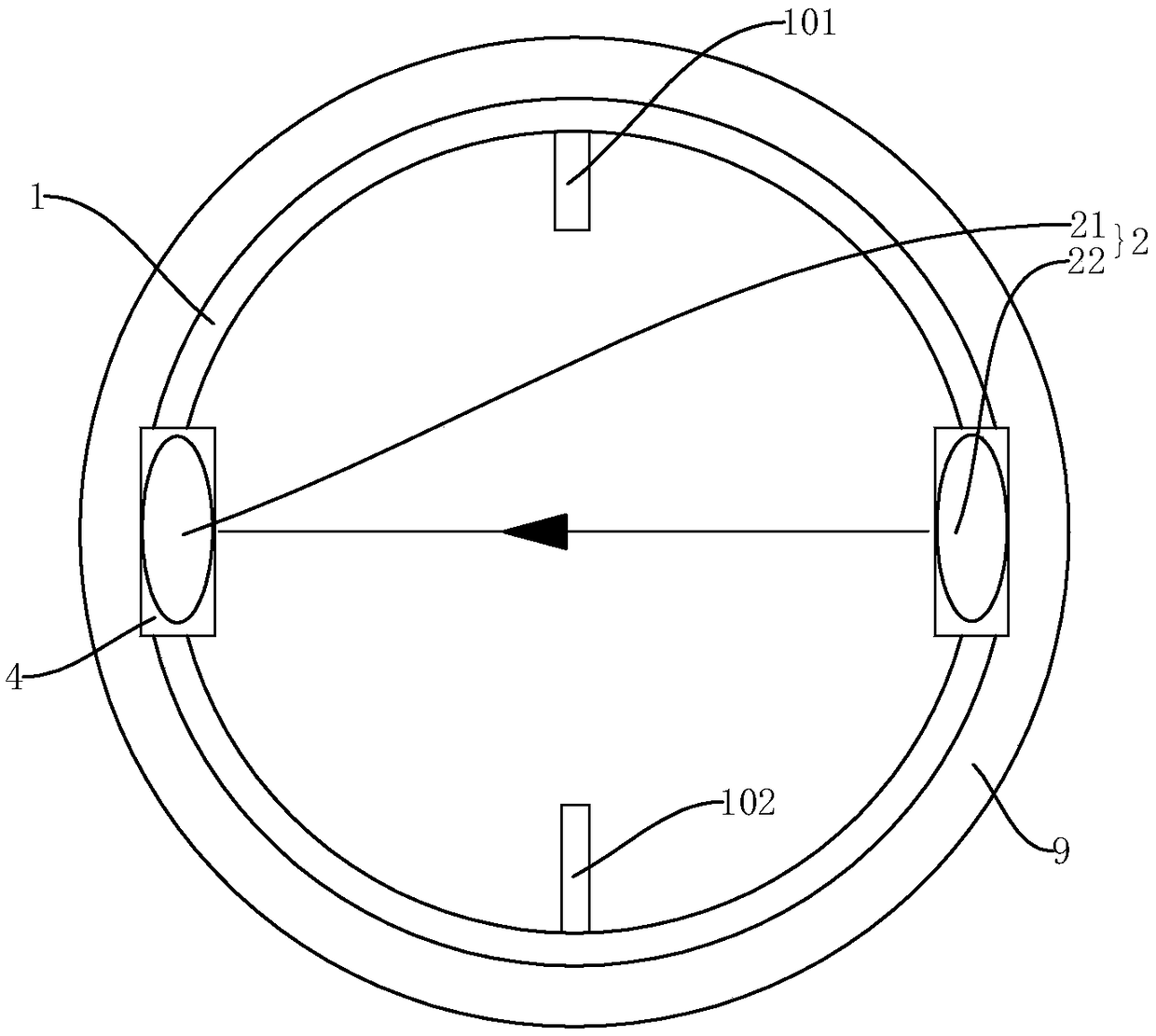

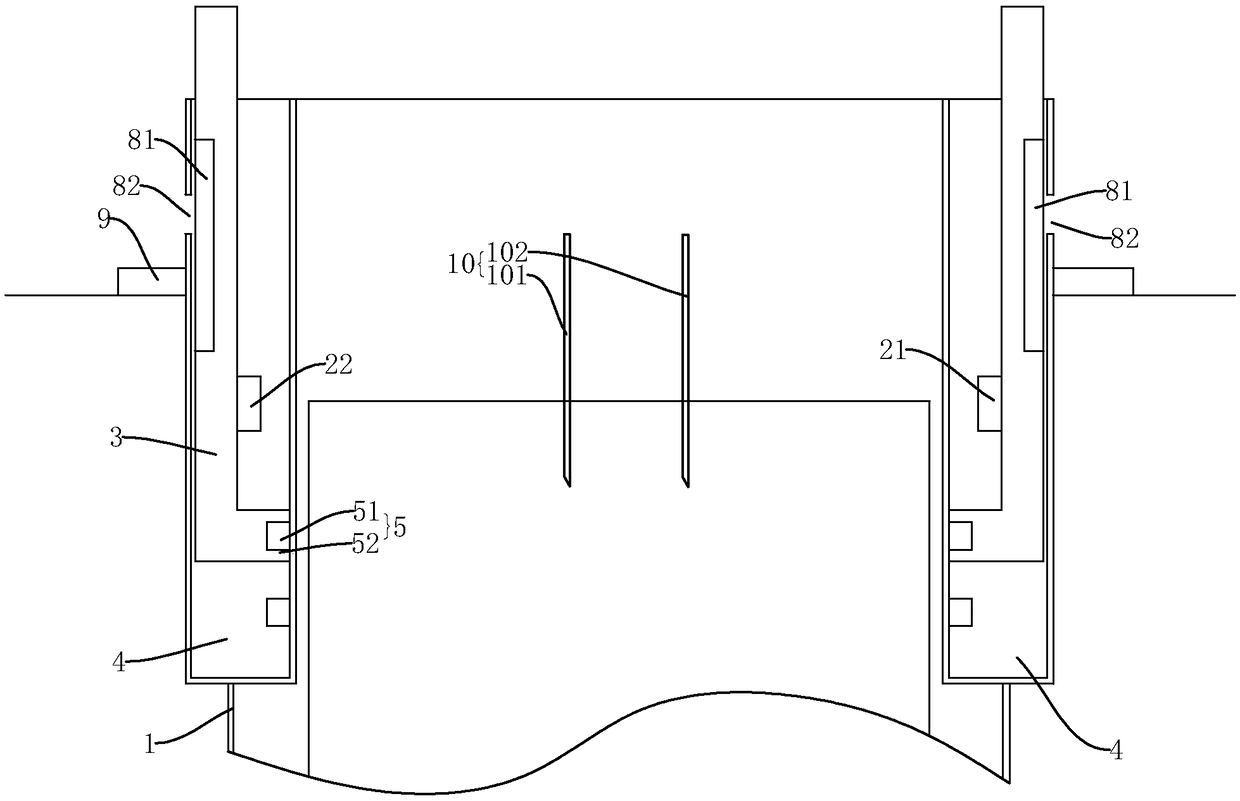

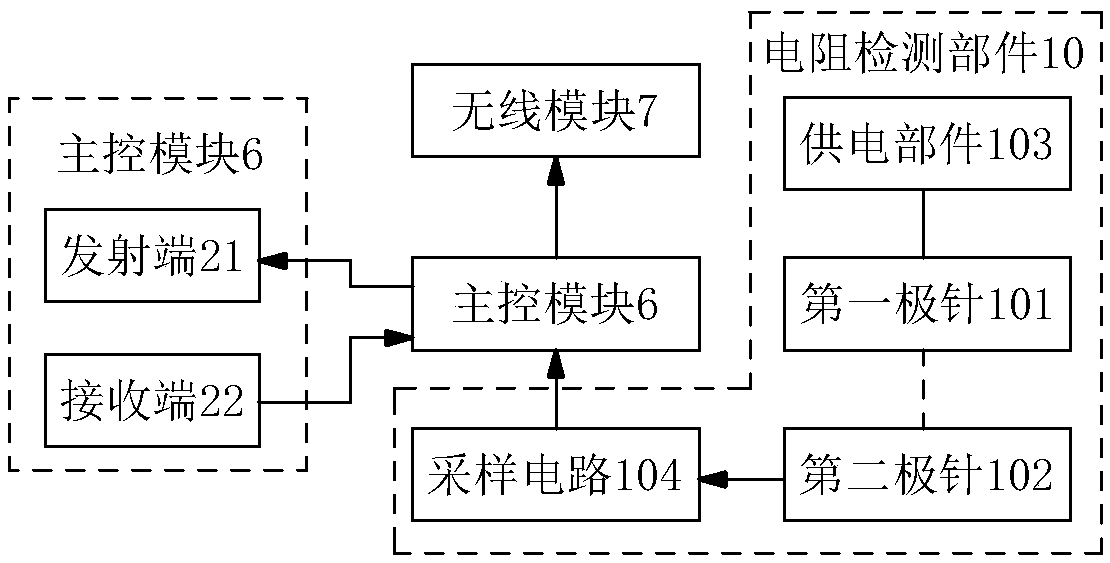

[0018] Such as Figure 1-Figure 3 As shown, the detection device of the present invention includes a fixed bracket 1 for being installed inside the piling hole / grouting hole, a photoelectric sensor 2, and a shelf 3 for placing the photoelectric sensor 2. The side of the fixed bracket 1 is provided with a The light-transmitting cavity 4 inserted into the frame 3, the inside of the light-transmitting cavity 4 is provided with a height adjustment mechanism 5, and the rack 3 is connected with the light-transmitting cavity 4 through the height adjustment mechanism 5 to be able to adjust the light output height of the photoelectric sensor 2; The main control module 6 and the wireless module 7 capable of connecting the main control module 6 with external devices through wireless communication, the main control module 6 is electrically connected with the photoelectric sensor 2 and the wireless module 7 respectively.

[0019] Wherein, the main control module 6 may be composed of MCU or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com